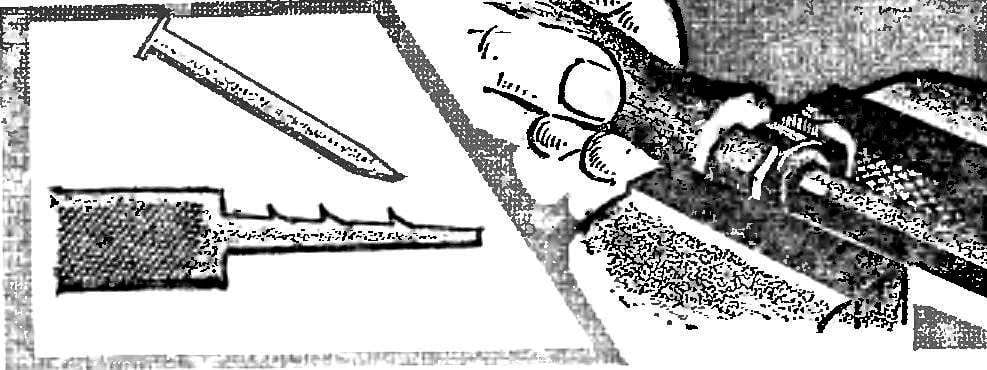

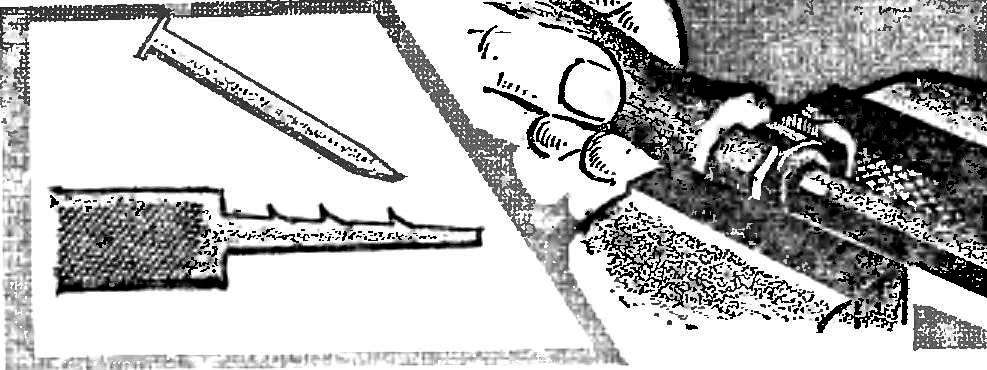

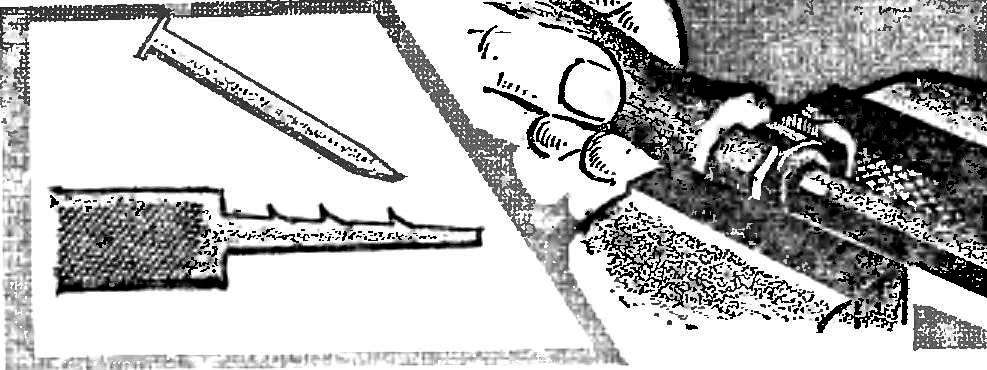

Wood handle plumbing tools will eventually fail and require replacement. Buying or making a new one, not in a hurry to wear it. First, on the shank of the chisel rasp, make several oblique notches — they firmly hold the handle of a jump-out, and that lasts a little longer, put it on the front neck of the metal bushing and squeeze in the vise with the cut on the large diameter nut.

Wood handle plumbing tools will eventually fail and require replacement. Buying or making a new one, not in a hurry to wear it. First, on the shank of the chisel rasp, make several oblique notches — they firmly hold the handle of a jump-out, and that lasts a little longer, put it on the front neck of the metal bushing and squeeze in the vise with the cut on the large diameter nut.

Recommend to read

COMBINATION LOCK

COMBINATION LOCK

About code locks wrote more than once. However, most of them are difficult to repeat. Design suggested by our Bulgarian friends (the journal "Radio Television Electronics"), devoid of... NUCLEAR MISSILE KILLER

NUCLEAR MISSILE KILLER

(Continued. The beginning in № 3 2005) Supersonic strategic bomber CONVAIR B-58 HUSTLER. Not waiting for the completion of flight tests, August 1, 1960 the U.S. air force has...

Wood handle plumbing tools will eventually fail and require replacement. Buying or making a new one, not in a hurry to wear it. First, on the shank of the chisel rasp, make several oblique notches — they firmly hold the handle of a jump-out, and that lasts a little longer, put it on the front neck of the metal bushing and squeeze in the vise with the cut on the large diameter nut.

Wood handle plumbing tools will eventually fail and require replacement. Buying or making a new one, not in a hurry to wear it. First, on the shank of the chisel rasp, make several oblique notches — they firmly hold the handle of a jump-out, and that lasts a little longer, put it on the front neck of the metal bushing and squeeze in the vise with the cut on the large diameter nut.