Multifunctional device consisting of copier, printer and scanner (hereinafter, MFP), it is useful not only for home or office desktop. In practice, there are times when a copier, printer or scanner is required to literally “here and now”. For example, they are often necessary for a “hike” in state institutions. The device is so popular in modern life, when visits to bureaucratic offices require copies of the documents becomes irreplaceable. It can be used to scan the same documents and prepare them for sending via e-mail.

Multifunctional device consisting of copier, printer and scanner (hereinafter, MFP), it is useful not only for home or office desktop. In practice, there are times when a copier, printer or scanner is required to literally “here and now”. For example, they are often necessary for a “hike” in state institutions. The device is so popular in modern life, when visits to bureaucratic offices require copies of the documents becomes irreplaceable. It can be used to scan the same documents and prepare them for sending via e-mail.

Such a possibility appears in the “upgrading” of the home computer peripherals when the old, but in good working MFP is replaced by a more modern model remains, so to speak, “out of business”. So, given the small mass of the MFP (for example my F2180) and easy transport, it is possible to give a new “offline” life.

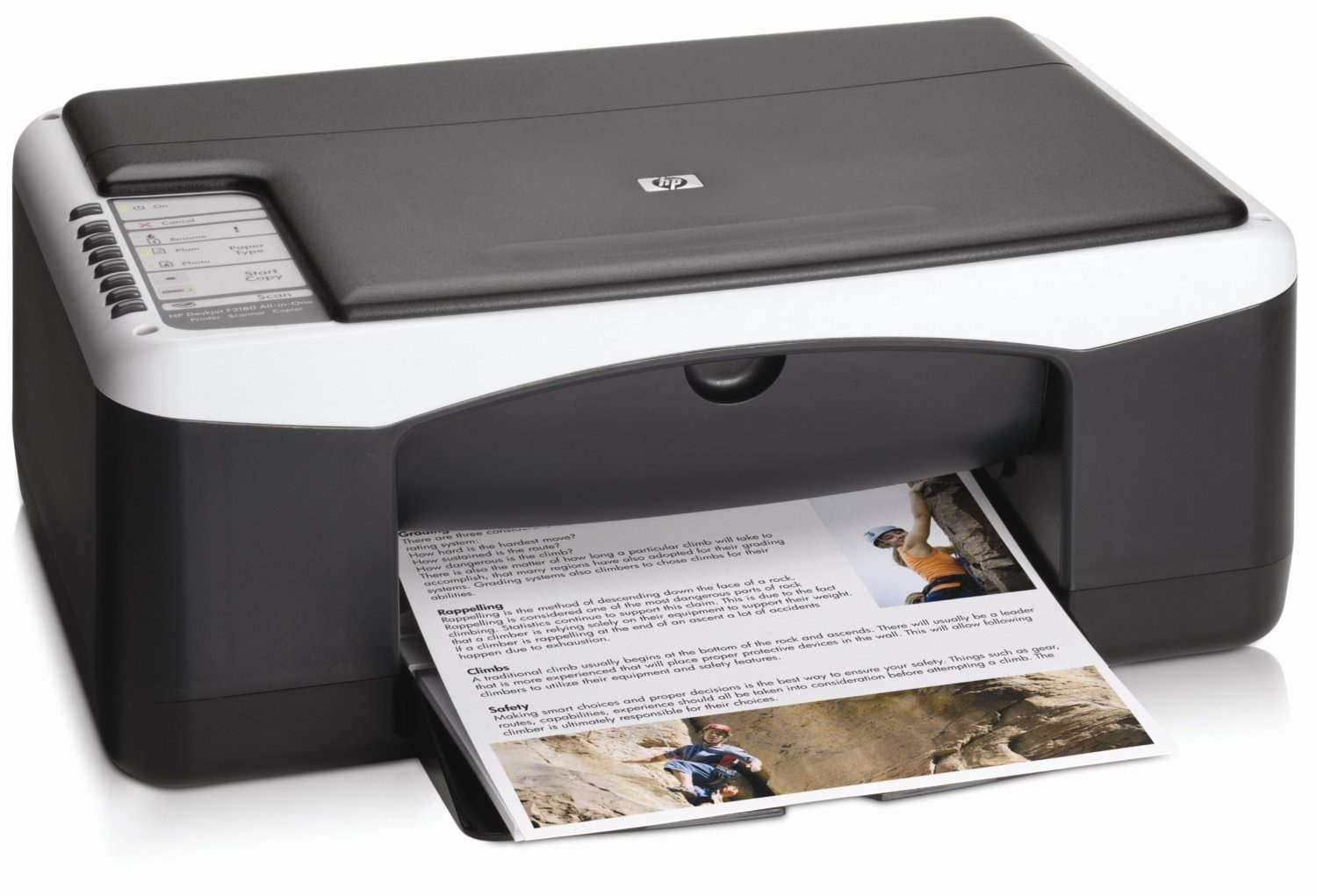

Almost all such devices for household purposes feed a variable voltage from the lighting network 220 V with a frequency of 50 Hz. Here’s my MFP HP Deskjet F2180 model is powered by 220 V via adapter, giving two modified output voltage required to operate the device: 16 (max current consumption in the circuit is 500 mA) and 32 (maximum current is 300 mA). But here’s the problem: how to enable (power) MFP where 220 V no?

The DECISION

At first glance, the simplest solution is to ensure the autonomy of the IFIs in the car (and everywhere, where is not possible to connect to a lighting network 220 V, but there is power supply from the DC power supply 12-16V) is to connect it through the adapter-inverter 12 – 220 V (for example, the model of Porto HT-E-350S DC12V/AC220V 350 W photo).

Its specifications, including form of the output signal is”pure sine”, is it possible to do it: output voltage: -220 V±5%, output frequency – 50Hz ±1 %, for short periods (starting) power is 600 W, the efficiency is 85%.

Adapter voltage Converter is protected against overload, short circuit, overheat, over/under input voltage, works well under ambient temperature from -10°C to +50 °C. Has a forced cooling (fan) and the idle current less than 0.4 A (no load connected).

MFP installed in the car

For the considered in this article purpose suit and the other voltage Converter “DC-AC” 12V/220V with similar electrical characteristics. Having output power of 350 W, the Converter can solve the problem with power different devices connected to the vehicle by its owner, such as laptop and tablet computer, mobile phone and even multifunction centre that turns the car into a mobile office. But, unfortunately, such consumers as electric kettle and coffee maker will not run from this Converter as consume more current (and power). So that “power” of the MFP in the car, you need to connect your device using recommended and proven Converter 12/220 V power over 300 watts. But this raises another question: is it possible to make the power of the MFP is fully Autonomous and independent even from the onboard network of the car?

INDEPENDENT POWER

It turns out that you can. For this it is necessary to provide voltage equivalent to 10 V (minimum input voltage at which the Converter Porto HT-E-350S DC12V/AC220V working effectively and provides at the output of the network voltage and is required to power the MFP power). Experiment with battery 12 V power consumption 7.2 Ah showed that this is possible.

But the battery СТ1207 quite heavy though, instead, it will fit another, for example AGM VRLA Delta DT12012 (12 V, 1,2 Ah), the mass of which only 300, But it is inconvenient to mount on the Converter housing, and moreover, no battery, no Converter can not “squeeze” into the housing of the MFP.

Converter connected to the battery Delta ST 1207

Therefore, for the realization of the idea, I bought three plastic box for AA battery (batteries) AA-size batteries; each box includes four battery/element is connected in series. These boxes, or as they are called, “4АА compartments, closed with shutdown and power connector” have different (not standardized) modifications and designations, so I do not cite names. Importantly, this fits the battery compartment four batteries (or battery) and the voltage at the conditions of the serial connection of all batteries/ battery compartments, respectively 18/14,4 V. the Difference is due to the fact that the nominal battery voltage is 1.5 V, and the battery of the same size is 1.2 V. I focused on the fact that the boxes will be laid exactly Ni-Mh rechargeable batteries the energy capacity of 2000 mA·h (experimented with battery firms Minamoto). Therefore, and found 4 boxes of “stock” voltage.

Special attention should be given to how to strengthen the boxes (battery compartments) to the aluminum enclosure. Indeed, not every glue will create a reliable connection of the two difficult (based on the set in the boxes battery) devices.

INDISPENSABLE GLUE

If you need to glue the two surfaces so that they survive the weight on the gap of about 120 kg, without my recommendation is not enough. But today let’s stick together “forever” plastic box and adapter-voltage Converter Porto HT-E-350S glue Fix-it, since no other adhesive has after drying such a “powerful” qualities. He can even glue the stones. Technical characteristics of the adhesive connection is highly resistant to water and frost (ambient temperature of -40 °C) and heat (+100°C).

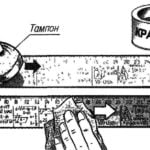

Both surfaces clean (degrease optional) and apply from a tube large drop of glue thickness of 2…3 mm. This is the case, if the surface is not flat (sloping panel), therefore a drop of glue should be impressive.

The method of applying the adhesive on the surface

Installation boxes for batteries on the body of the adapter-Converter

Such a drop should be applied and on the battery compartment. Then surfaces must be lightly pressed to each other so that their adhesive layers “vzaimoponimanie”. On the surface it is necessary to separate (explode) a few seconds apart, and again to connect and hold for 2 – 3 minutes, perched on top of, for example, iron. For high-quality crimping surfaces you can also use a vise or clamp.

Bonding time is 24 hours. During the day the bonded parts need to be fixed; to do this, they must be tough to fix. As a striker you can apply the appropriate clamping plastic or metal clamps, clamp, home Vice, and simple pressing on top of more heavy stone – depending on the specific situation and shape of bonded parts.

Adhesive ability of the glue of the imagination. The binder is synthetic rubber in a light grey colour. The glue – almalikski solvent mixed with hydrocarbons. The shelf life of the adhesive stored in the package, two years. This glue is indispensable in the car and wherever you need reliable connection previously unprocessed parts.

ATTENTION!

The glue is flammable, irritating to skin. When involuntary inhalation may dizziness. May cause adverse effects in the aquatic environment.

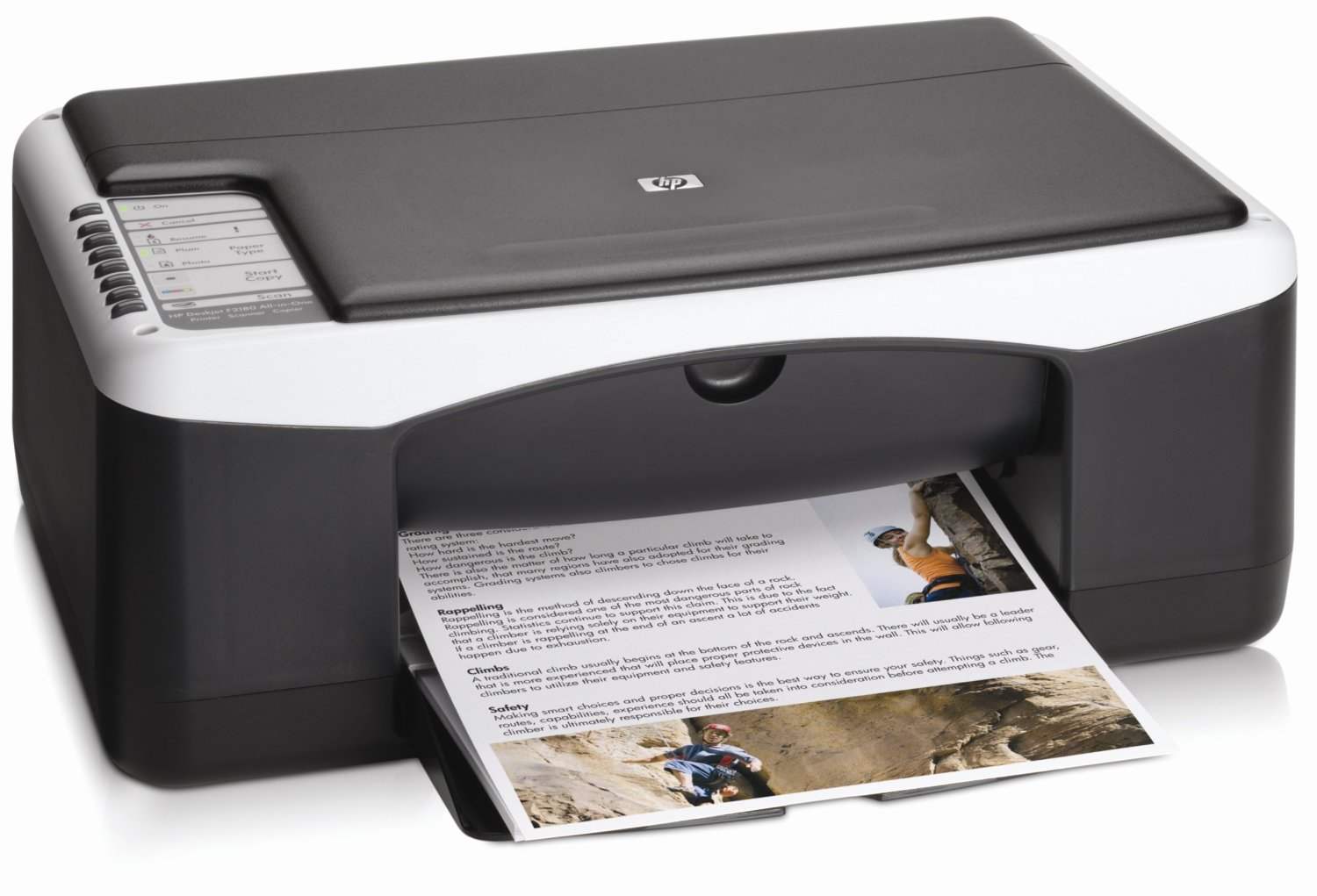

Thus through a simple Converter Porto HT-E-350S was transformed into an Autonomous source of network alternating voltage of 220 V, which can be universal and apply regardless even of the printer (MFP). Given the fact that the transducer is placed four boxes for batteries (battery) with a supply voltage in Autonomous form, it can run for up to one year -with frequency of use (on MFP) once a week. It is tested in practice.

The final drive unit battery compartments looks as a single device.

The photo shows the real work of MFP with implemented idea for improvement – in my car.

MFP can carry in the car. The space it occupies is little, and the benefits from it most: the car turns into the office during visits to state bodies when they want to make a lot of copies of documents, and sometimes to provide them in electronic form.

On vacation, you can print photos, which is very convenient on vacation (when you install the MFP with a color or photo cartridge). So, in the specific case of my old MFP comes to the rescue and saves the budget.

It must be borne in mind that in the cold season, when the air temperature falls below +5°, the MFP must be carried out in a warm place (home) to save not only his mechanical parts, battery, and cartridge with ink in it in negative temperatures to change their properties and may even freeze.

A. KASHKAROV, g .Saint Petersburg