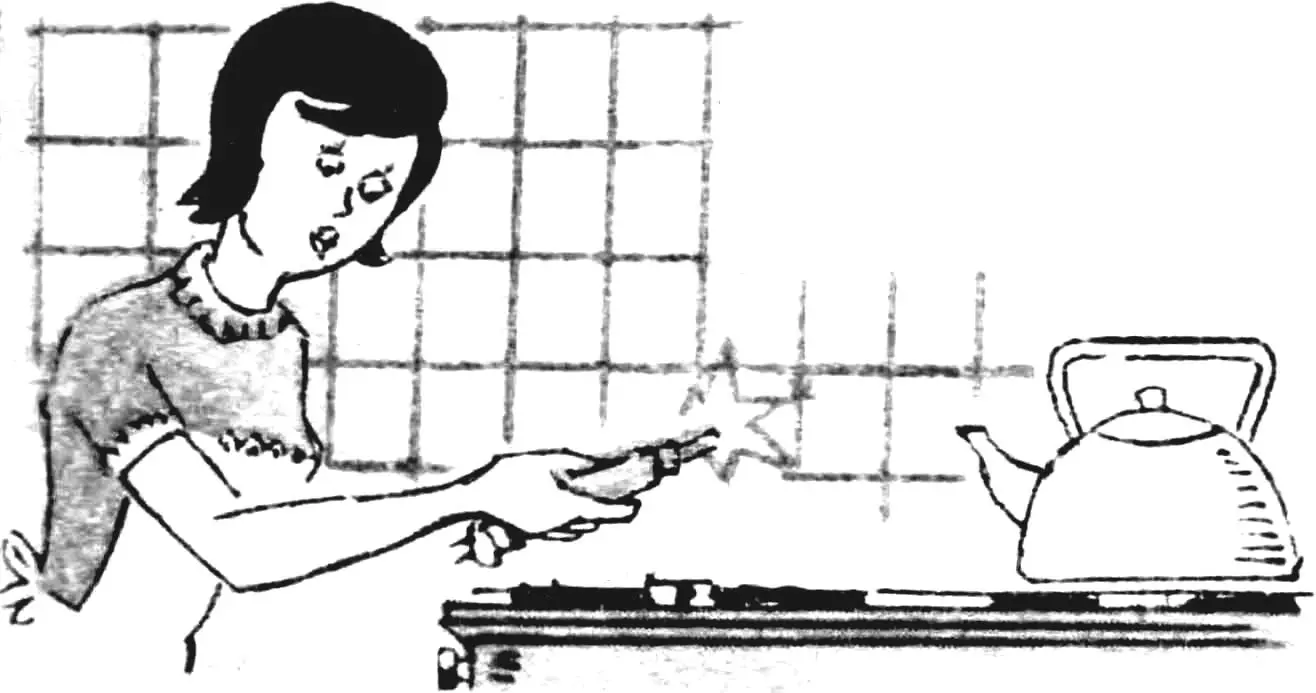

They say you can’t save much on matches, and yet… A simple and practical electronic “match,” the description of which we offer to readers’ attention, will free you from the need to constantly monitor that matchboxes don’t remain empty.

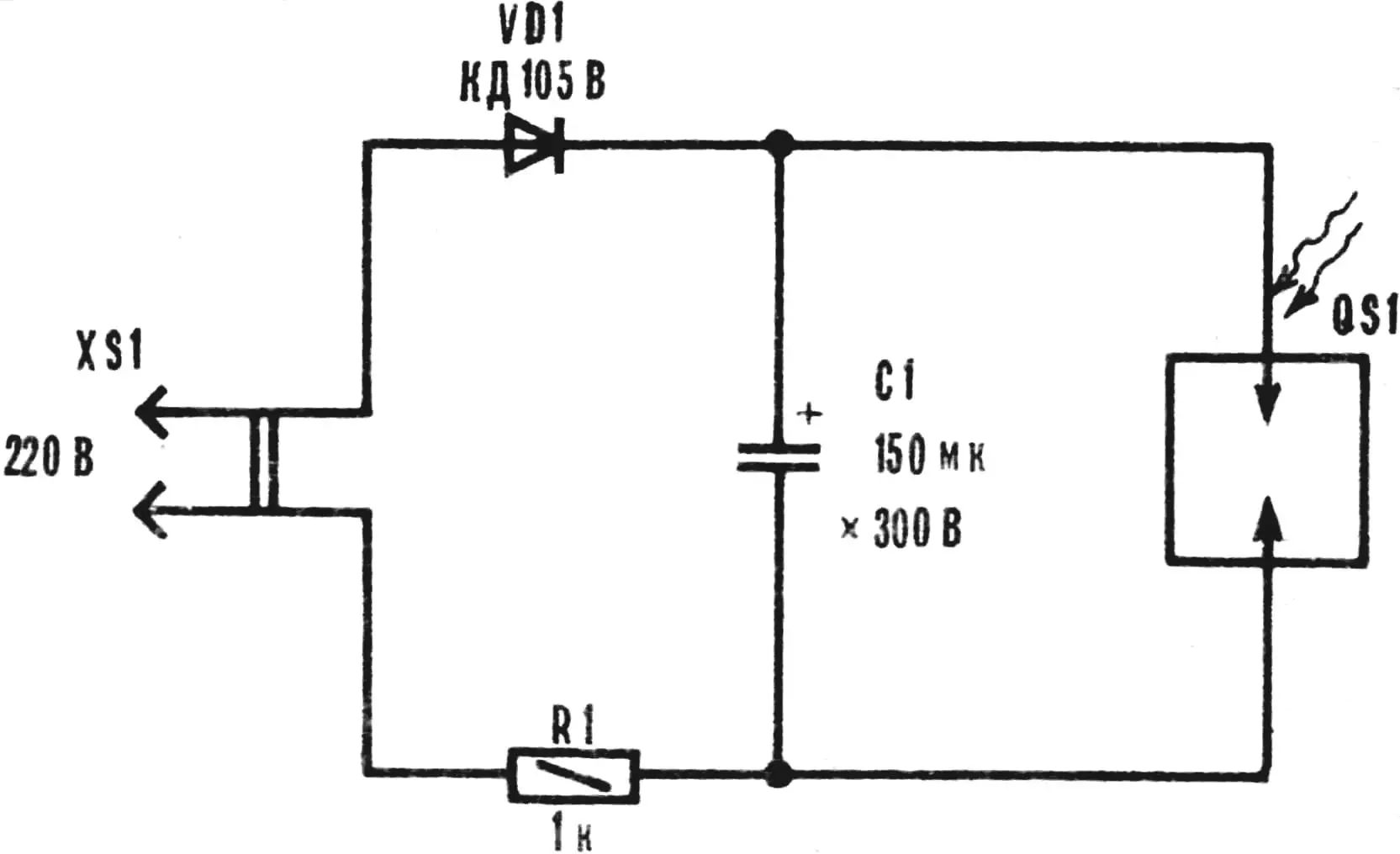

The “match” works as follows. The electrical energy accumulated by capacitor C1 (see the schematic diagram) from the 220 V mains is converted into a spark, which ignites the gas in the burner of a kitchen stove. The time to charge C1 to the peak mains voltage is 2—3 s, and only 0.1 s is sufficient for its discharge.

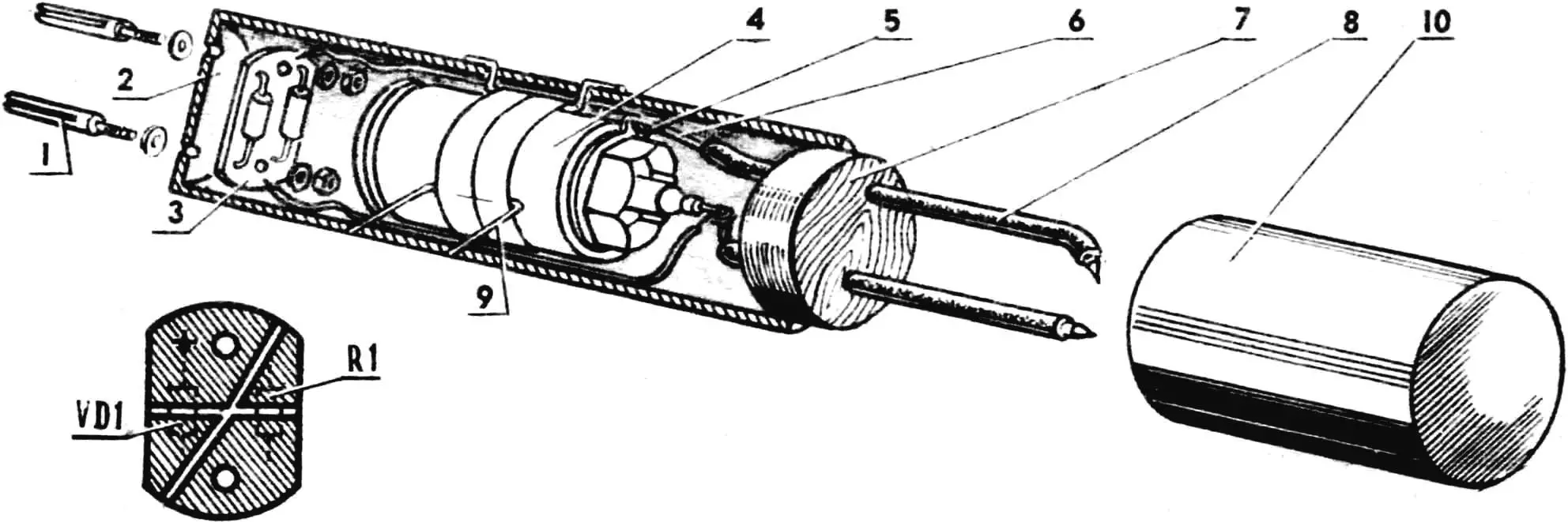

Structurally, the “match” is made in the form of a cylinder consisting of two halves (see fig.). Radio components are placed inside one, the other protects the spark gap ends from accidental shorting, otherwise the “match” connected to the mains immediately damages diode VD1, which protects against a shock from capacitor C1 discharge (when touching the plug’s current collectors after removing it from the mains socket), since relative to the voltage polarity on it, the diode is connected in reverse direction.

The “match” is assembled from any available materials. Plastic shampoo bottles 100 mm long are used as the composite housing. Part dimensions are selected to fit their dimensions.

Two holes are drilled in the housing bottom for current collectors from a standard mains plug, the distance between which is calculated for the corresponding socket. Six more Ø1 mm holes are made on the side—two each with a 120° spacing—for mounting the capacitor.

Next, a mounting board is made from foil-clad fiberglass 1…1.5 mm thick. The foil is cut with a knife into 4 segments (see fig.), to which the diode and resistor are soldered, as well as multi-strand insulated wires 150 mm long for connection to the capacitor. The board is fastened to the inner side of the housing using the current collectors and nuts.

The spark gap is made from welding electrodes Ø2.5 mm. Chlorovinyl tubes are put on them and inserted into holes in a wooden holder. The spark gap electrodes are sharply sharpened with a file at one end, and at the other end they are soldered to the capacitor leads. Moreover, the electrode sections intended for soldering are pre-wrapped with tinned copper wire Ø0.2 mm.

1 — current collectors, 2 — housing, 3 — mounting board, 4 — capacitor, 5 — wire winding for soldering, 6 — electrode, 7 — wooden holder, 8 — chlorovinyl tube, 9 — fixing bracket, 10 — cap

Using electrical tape, three brackets made of Ø1 mm copper wire are fastened to the capacitor housing with a 120° spacing, with a “reserve” in length. Wires coming from the board are soldered to the capacitor, and then, threading the bracket ends through holes on the side of the housing, the capacitor together with the spark gap is inserted into it to half the length of the wooden holder. A layer of “Moment” glue is pre-applied to this section to secure the holder in the housing. In addition, the bracket leads are bent along it from the outside, thereby fixing the “innards” of the construction. Their excess is cut to length, and the remaining bracket ends are glued to the housing or wrapped with electrical tape.

A protective cap is put on the other half of the electrode holder, which is outside the housing.

The “match” can be permanently plugged into the mains socket, so it is always ready for use. To light a gas stove burner, the “match” is removed from the socket, the protective cap is taken off, it is brought to the burner, the gas is turned on, and the spark gap is squeezed until the sharply sharpened electrode ends make contact—a spark occurs. When the spark gap is released, the elastic electrodes return to their original position. The protective cap is put on, and the “match” is inserted back into the mains socket until next time.

With prolonged use, the electrode surfaces eventually become “pitted.” Therefore, it is periodically necessary to clean the places of their mutual contact with a file, so that the spark gap ends are always sharply sharpened to concentrate the capacitor discharge energy in a narrow area.

The diode can be replaced with any other with similar parameters.

A. KUBAREV, A. CHUMAKOV