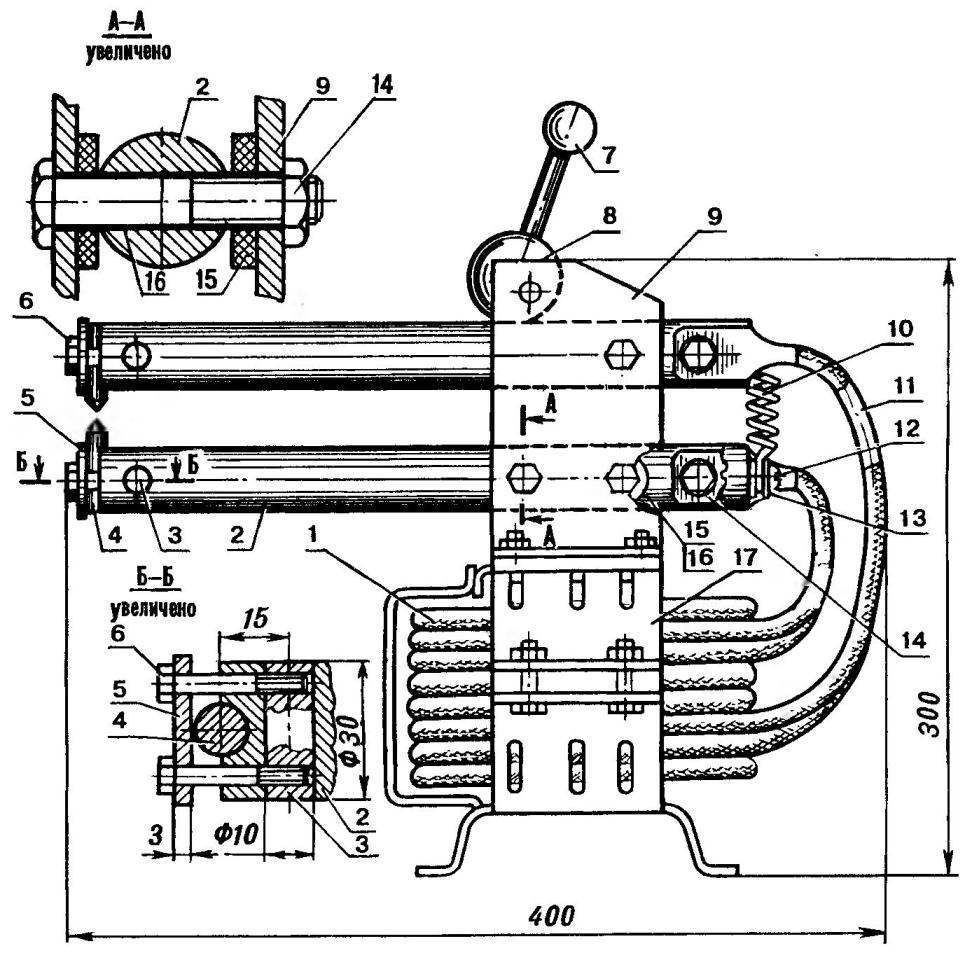

Holders recommend electrodes made of duralumin, isolated from cheeks textolite washers and mounting bolts M8 — varnished cloth or protective adhesive tape on cotton basis. The electrodes themselves are advised to use copper with a diameter of 12 mm, fixing them in the holders with rectangular brass washers and two M6 screws for which the special steel inserts prudently made appropriate thread.

In the initial position holders with electrodes divorced a spring with suitable dimensions (for example, from old beds-Raspadsky). But we must make sure that the spring did not create a short circuit on the terminals of the secondary winding during operation of the welding transformer. One of the acceptable technical solutions is, in particular, the variant with application of the separation of the plastic sleeve, secured in the fixed end of the electrode holder screw M6. The lower end of the spring is electrically isolated from all other parts “svarochnik” under any, even the most incredible situations.

Apparatus for spot welding sheet steel:

1 — transformer OSM-1,0 finalized; 2 — conductor (aluminum rod Ø30, L 300, 2); 3 — liner (steel rod Ø10, L30, 2pcs); 4 — electrode (copper rod Ø12, L50, 2pcs); 5 — puck brass (2 PCs); 6,12 – M6 screws; 7 — handle; 8 – eccentric; 9 — cheek (2 PCs); 10 — spring; 11 — the withdrawal of half of the secondary winding (4 PCs.); 13 — textolite bushing (with groove under the end loop of the spring); 14 — bolt M8 (6 PCs); 15 — the textolite washer (4 PCs); 16 — insulating coating (varnished cloth or protective adhesive tape on fabric base, 2); 17 — a casing of the transformer.

Wiring diagram of the apparatus to a household outlet.

Connect the welding machine to the network, preferably by the well-proven wiring diagram (see Fig.) through the automatic 20-amp breaker. On a similar (at least!) current must be calculated and the meter. Well, direct control of “svarochnik” — with the help of magnetic starter K1, turn on the pedal with the button S2 of the type “fungus”. The housing and the secondary winding of the transformer must be grounded.

To turn on and off a “svarochnik” it is only necessary to tight the electrodes. Failure to observe this simple rule can lead to the occurrence of intense sparking, which leads to burning of the electrodes with highly undesirable consequences.

And one more, verified by practice, the Board. Since forced cooling is not provided to the transformer or conductors and electrodes during the welding should continuously monitor temperature. As necessary to do breaks in work, but in any case, to prevent overheating of the equipment.

GAVRILOV, G. G mistletoe, Republic of Belarus

Recommend to read

SPEED JIGSAW

SPEED JIGSAW

Existing jigsaw has a number of disadvantages. Minor fluctuations in the amplitude of the nail (5 mm) does not allow to increase the speed of cutting both thin and thick plywood. Machine... THE CORRUGATED BOARD MOTOR

THE CORRUGATED BOARD MOTOR

Not so long ago in the journal "modelist-Konstruktor" was about the simplest model of a glider made from a conventional packaging corrugated Board material although not aeromodelling,...

I made welding machine is a well-proven in practice a modernized version of the device description and drawings of which are published in the journal “modelist-Konstruktor” No. 3, 1966. Most importantly — new “svarochnik” significantly more powerful than its predecessor, easier to manufacture and operate. In the absence of the kind of “bells and whistles” it allows you to securely connect steel sheet with thickness up to 3 mm. However, the mode of operation is one of the most necessary most homebrew spot welding.

I made welding machine is a well-proven in practice a modernized version of the device description and drawings of which are published in the journal “modelist-Konstruktor” No. 3, 1966. Most importantly — new “svarochnik” significantly more powerful than its predecessor, easier to manufacture and operate. In the absence of the kind of “bells and whistles” it allows you to securely connect steel sheet with thickness up to 3 mm. However, the mode of operation is one of the most necessary most homebrew spot welding.