Holes in wood, plastic or duralumin parts are usually done in two steps: first, through drilling, and then chamfering with the core drill or drill bits of large diameter. I suggest a simple device that allows you to combine these operations.

Holes in wood, plastic or duralumin parts are usually done in two steps: first, through drilling, and then chamfering with the core drill or drill bits of large diameter. I suggest a simple device that allows you to combine these operations.

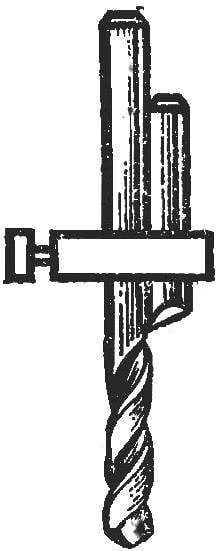

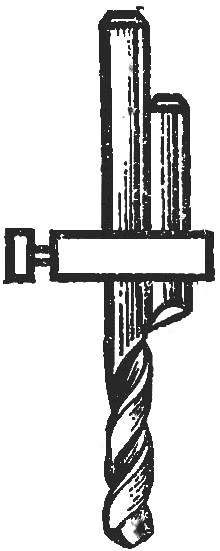

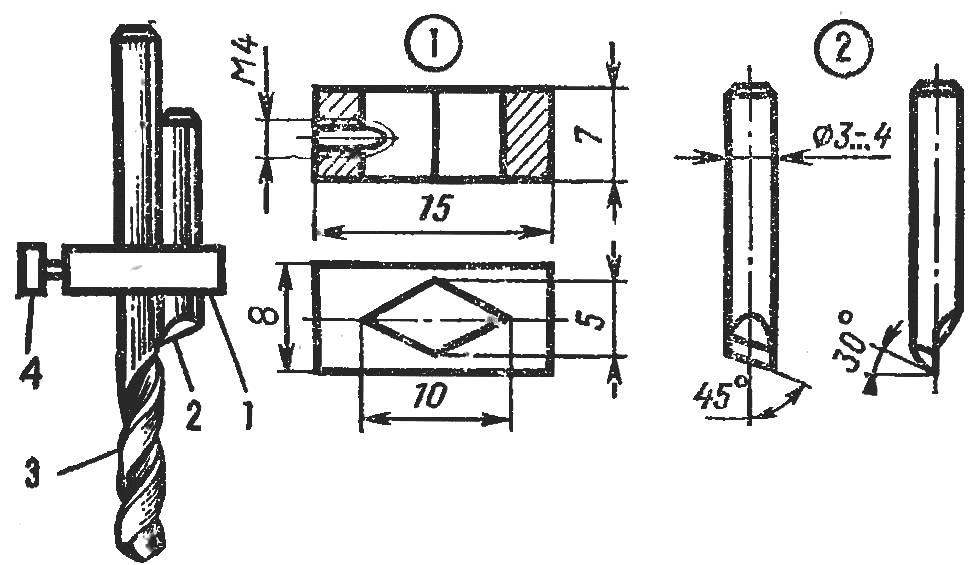

A device for simultaneously drilling with chamfer:

1 — mandrel, steel 40H, 2 — cutter, 3— check, 4 — fixing screw M4

A small chisel made from a piece of drill or tap is fixed on the working tool by means of a spindle with a diamond-shaped hole. After the drill bit deepens the distance specified by the position of the cutter, the edge is removed chamfer.

And, ALIMOV, Moscow