2 . It has a quite satisfactory capacity to fill it is easy, fuel is not harmful to children. Today in the Moscow city station of young technicians developed several types of models for competition of Junior high school students and first control line racing, Svobodnaya the replica model and timer model airplane. Today we introduce readers to “M-K” with “timerkey”, which showed very good results in numerous experimental runs.

Wing model aircraft with a single-spar, with a single pine shelf. Section shelf 6X1,5 mm at the root and 3X0,8 mm at the wing tip. “The forehead” of the wing sewn on top of the balsa with thickness of 1 mm. Distance between the shelf and the balsa covering is filled with balsa with thickness of 1.2 mm. the Front and rear edge of lime. The front edge has a cross section of 4X1 mm and the rear is wedge-shaped in cross-section, its width 10 mm. All the ribs are made of balsa with thickness of 1.2 mm, with the exception of docking (4 mm thick) and three root of mm plywood. At the root ribs at the locations of the holes for the pins of the hinges consoles pasted celluloid of a thickness of 1 mm. Finished wing upholstered Mylar film with a thickness of 0.01 mm.

Stabilizer. Beam flange phony, cross section 0,9X3 mm in the center and 0,5X1,5 at the ends. Ribs of balsa wood 1 mm-thick Central rib is balsa, with a thickness of 4 mm. also the Front edge of the balsa as the rear. The width of the edges of respectively 3 and 6 mm.

Kiel. Its front and rear edges of the balsa with a width of 5 mm. Ribs — balsa with thickness of 2 mm. After Assembly, the keel vyshkurivaetsya to a thickness of 3 mm at the root and 2mm at the end. The rudder is balsa attached to the keel by means of aluminium plates with a thickness of 0.2 mm. Cording to the keel and stabilizer — also of the Mylar film with a thickness of 0.01 mm.

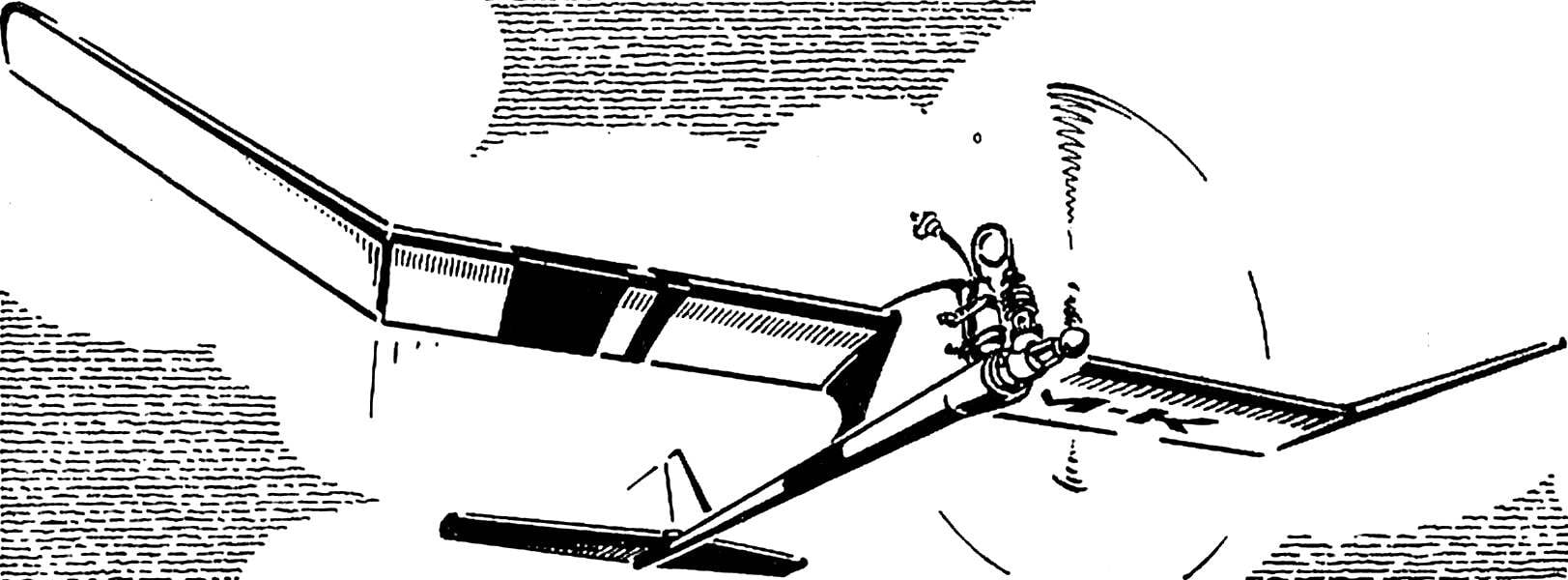

Timer model with pneumatic engine:

1 — rib wings (balsa with thickness of 1.2 mm), 2 — the lining of brow wing (balsa 1 mm thick), 3 — pins of the hinge wing (wire grade optical fiber; front — Ø 1,5 mm, rear Ø 1 mm), 4 — wing, 5 — reinforcing the gusset plate, 6 — motor with gas tank, 7 — screws of fastening of the engine (M2), 8 — pins fastening the gas tank (bamboo, Ø 2 mm), 9 — timer, 10 — tail boom (Vileika from steklosetkami epoxy resin), 11 — Kiel, 12 — stabilizer, 13 — pylon wing, 14 — a wall of the spar, 15 — shelf side member (pine section 6X1,5 mm at the root and 3X0,8 mm at the wing tip), 16, 17 — the front edge of the wing (Linden) 18 — the trailing edge of the stabilizer (balsa cross section 8X1,5 mm), 19 — rib stabilizer (balsa 1 mm thick), 20 — beam flange of the stabilizer (lime cross section 0,9X3 mm on the symmetry axis and 0,5X1,5 mm on the ends) 21 — the leading edge of the stabilizer (balsa section 2,5X2,5 mm) 22 — tip of the stabilizer (balsa), 23 — wing tip (balsa).

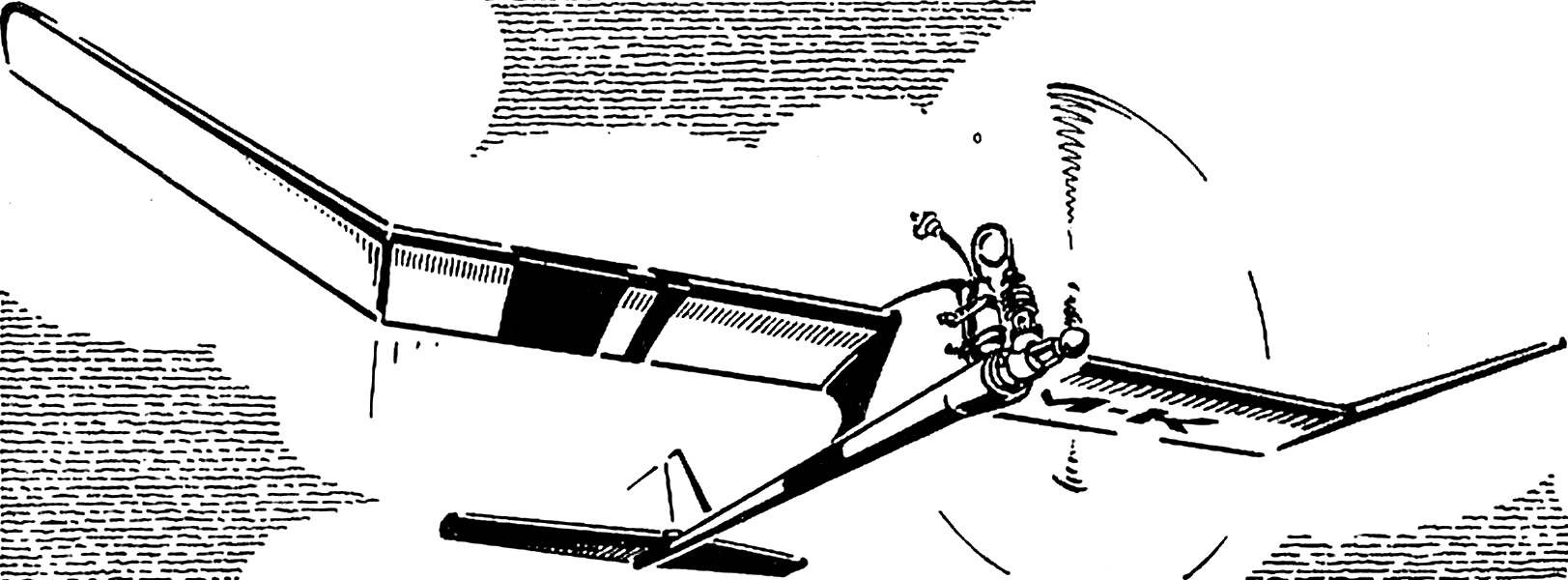

The composite wing for Tierney of aircraft (dimensions correspond to the balsa wing version):

1 — strengthening of the wing (carbon fiber with a thickness of 0.12 mm), 2 — the body of the hinge wing (balsa), 3 — foam based wing, 4 — wing (fiberglass thickness of 0.03 mm), 5 — cover hinge wing (plywood with a thickness of 1 mm).

Many readers of the “M-K” balsa “dimerco” we are not hoping that this option will be massive. Of course, balsa is the material for this model is beautiful, but not the worst and the foam modification.

If you have a good granulated foam all planes can be made from this material. Their production technology is the following. Templates hot current of nichrome wire Ø 0.2 mm is cut out of the foam billet. The current in the circuit of the heater-wire is selected in such a way as to allow minimal burning of foam and the best surface finish. Further to the ends of the workpiece are glued balsa ribs, and the billet center section is inserted into the glue on the attachment points of the pins of the hinges consoles. After final contouring of the wing — profiling of the foam surface pasted with fiberglass with a thickness of 0.02 mm on epoxy resin. To ensure the rigidity and strength of the wing trailing edge at the time of pasting laid strips of carbon fiber. Then the fiberglass is overlaid with Mylar film with a minimum thickness of 0.2 mm and the whole “sandwich” is clamped via desyatiballnoy between the foam left after cutting out the foam pieces and flat sheets of particle Board or thick plywood. After curing of the resin is glued to the balsa leading edge.

The fuselage model is a conical hollow tube, which consists of two layers of carbon fiber and one layer of fiberglass with a thickness of 0.02 mm, wound with epoxy resin on a tapered mandrel. The diameter of the mandrel at the ends 16 and 5 mm. by the Way, not necessarily that she was turned. If you can not handle it on a lathe, you can manually make the mandrel of lime or straight grained pine.

Technology vyklicky on a wooden mandrel next. First you have to wound on a mandrel with an overlap at 5-10 mm Mylar tape with a width of 40-50 mm. the ends of the tape to secure the tape. To hide imperfections of the mandrel, the thickness of the polyester should be not less than 0.03 mm. Further to the surface of the glass laid on top of each other blanks in the following sequence: polyester, fiberglass, two layers of carbon fiber. Patterns should be done with a margin of 10-15 mm on the side. After impregnation of such a “sandwich” with epoxy all patterns are cut with a knife along the ruler to the size ensuring overlap of 3-4 mm After the removal of the scraps from the surface of the glass mandrel is rolled pattern simultaneously winding them on the mandrel. Then everything is clamped vinyl chloride tape wound turn to turn with overlap of 2-3 mm. in Front of the winding tape must the edge of the Dacron, which falls inside the overlap, move out. After curing of the resin tape is unwound, remove the top layer of Dacron and finished beam is removed with the crank in the direction of the turns of the lower layer of Dacron, which is then removed from the larger diameter beam.

The pylon model is assembled from balsa strips with a thickness of 6-8 mm and glued balsa with veneer thickness of 1.2 mm. In place of fastening pins of the hinges consoles are pasted dural sleeve. The front pin is made of wire OVS Ø 1.5 mm and has a total length of 100 mm. Rear pin — from wire OVS Ø 1 mm long 100 mm. For mounting gas tank in the pylon glued bamboo pins Ø 2 mm. From the engine side to the I-beam is glued balsa boss. Under the screws on the engine are pasted “fungi” with thread M2. On this model, used timer by “Graupner”, but it can be done independently from the clock mechanism from the camera “Kiev”. A timer activates a system of forced landing.

Hub folding single blade propeller:

1 — hub body, 2 — the butt cracker, 3 — spring 4 — nut-limiter, 5 — counterweight, 6 — bushing.

The blade of the screw:

1 — the blade (Linden), 2 — pin (aluminum), 3 — nut (duralumin).

Propeller. Staff, which is attached to a motor that has satisfactory characteristics at temperature of air not below +18°C. At lower temperatures the screw for the engine is “too heavy”. In addition, it provides a large aerodynamic drag in the gliding mode. On our own, “tierce” was used much more effective a single blade foldable propeller providing the launch of the model at temperatures of +5°C. the adjustable step allows to achieve the maximum efficiency of the screw in any weather. The presence of one of the blades simplifies this adjustment in the field. The blade screw is made of basswood. In the inboard portion affixed dural pin with thread M3. After processing the templates and profiling the blade is covered with two layers of Amalita macalintal and glued colored paper. Hub body screw made of alloy MA-8 on a lathe with subsequent milling and metal processing. From the same material machined billet inboard biscuit blades. After milling it together with the housing drilled hole Ø 2.5 mm under the dural sleeve. Further inboard, the biscuit is cut the limiter of rotation of the blade in working position. The spring providing the folding of the blades is bent from wire OVS Ø 0.3 mm and has three turns. Lead counterweight is fixed after balancing the screw on the terminal housing with the aid of duralumin nuts-limiters. Fixation of the screw pitch is the same nut. After final Assembly the end of the sleeve raskladyvaetsya (it is only necessary to see that the blade was formed easily).

So should be cut from foam billet wing:

1 — cutting the thread (nichrome wire, Ø 0.2 mm), 2 — the root template, 3 — rubber shock absorber, 4 — foam block, 5 — terminal pattern 6 — wood machine tormaresca.

The scheme of forming the tail boom. A wooden mandrel (1), protected polyvinyl tape (2). B — preparation of materials for vyklicky tail boom:

1 — carbon, 2 — carbon, 3 — glass, 4 — Mylar film, 5 — substrate (glass).

The scheme of forming composite wing:

1 — chipboard, 2 — foam (trimming), 3 — foam, 4 — Mylar film, 5 — fiberglass with a thickness of 0.02 mm, 6 — foam – wing, 7 — strips of carbon fiber with a thickness of 0.12 mm.

V. EISYMONT, head of model and technical Department of MGST, master of sports of the USSR

Recommend to read ETERNAL SCOOP No words, plastic dustpan easier and more hygienic than metal. But its working edge for strength are made thick, and it is an insurmountable barrier for dust: not just a broom, even... WRITTEN FROM THE DINING In my family there was a situation when my daughter went to first grade, and hence it took for her workplace, where they could prepare lessons. However, the area and the interior rooms... Scroll back to top

Without the engine the model doesn’t fly. But to rely on the ice today is not necessary: the mass of the motors is just terrible. You can, of course, many years ago, to do “resinator” but now this model guys inspire difficult. Meanwhile, there is the engine, capable of becoming the progenitor of a range of models for beginners air (though why not a car or ship) modelers. This is a pneumatic engine, working on liquefied carbon dioxide WITH2. It has a quite satisfactory capacity to fill it is easy, fuel is not harmful to children. Today in the Moscow city station of young technicians developed several types of models for competition of Junior high school students and first control line racing, Svobodnaya the replica model and timer model airplane. Today we introduce readers to “M-K” with “timerkey”, which showed very good results in numerous experimental runs.

Without the engine the model doesn’t fly. But to rely on the ice today is not necessary: the mass of the motors is just terrible. You can, of course, many years ago, to do “resinator” but now this model guys inspire difficult. Meanwhile, there is the engine, capable of becoming the progenitor of a range of models for beginners air (though why not a car or ship) modelers. This is a pneumatic engine, working on liquefied carbon dioxide WITH2. It has a quite satisfactory capacity to fill it is easy, fuel is not harmful to children. Today in the Moscow city station of young technicians developed several types of models for competition of Junior high school students and first control line racing, Svobodnaya the replica model and timer model airplane. Today we introduce readers to “M-K” with “timerkey”, which showed very good results in numerous experimental runs.