For turning. woodwork on the spindle is installed chetyrehochkovym cartridge, and on the bed — removable tailstock. The cartridge screws onto the spindle and contra nut. As the Cams are M8 bolts. The tailstock consists of a bracket, the center of which (welded nut) moves the screw with the handle. At its free end fits over the revolving center or a Chuck to clamp drill bits. The dimensions of the cartridge on the spindle and tailstock should be consistent with the magnitude of the publications that involve lathing and sizes and seats available or purchased parts, live center and a Chuck for drills. You need to keep in mind that for some turning wood cartridge CA. the spindle is not needed, you can limit to a simple “plug”.

On sale now almost all the needs of Amateur and sharpening the cutting tool, circular SAW blade diameter from 200 mm, the same wheels different zernistost”. Not in the manufacture of the frame it is necessary to provide possibility of installation on the spindle of circles Ø 300 mm with glued on them with emery cloth to perform the polishing work.

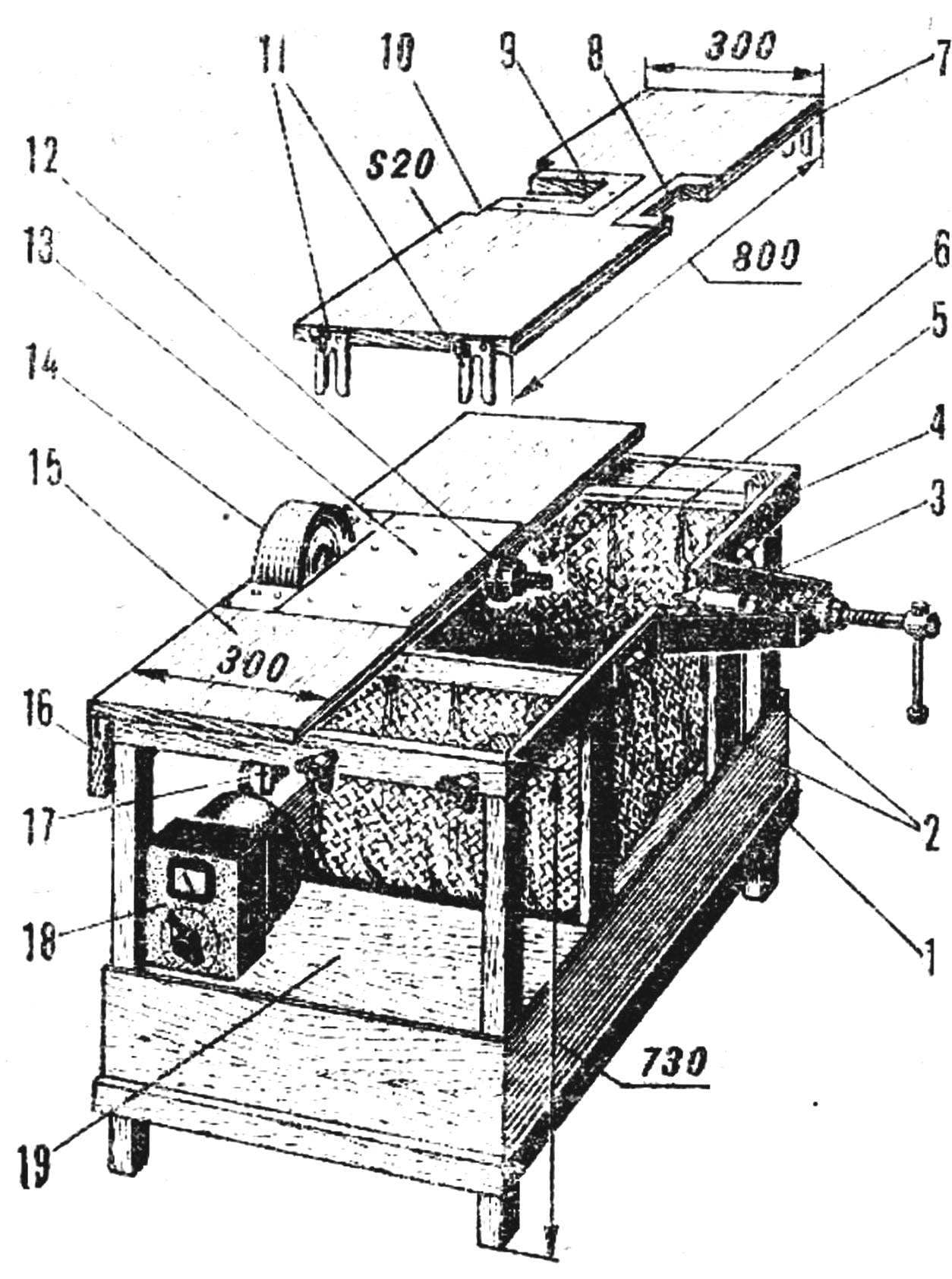

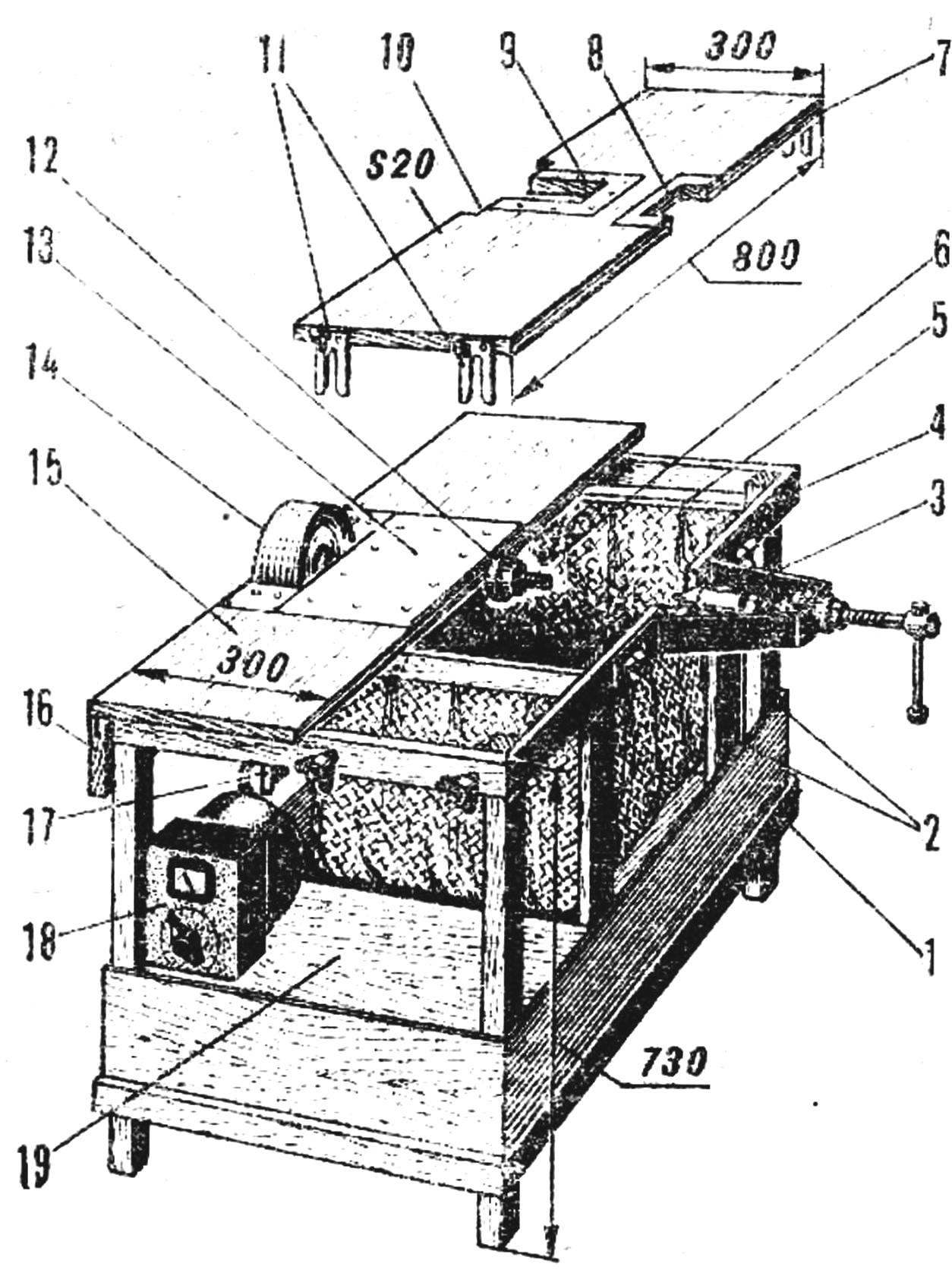

The design of the proposed “tank makes it easy to turn it into a electric plane. To do this, fabricate, steel cutter drum knives. For reel will fit the 20 steel, the knives should be made of khvg steel grades, P-9, 9KH5VF or R-5 (85Х4В4Ф) with heat treatment of LDCs 55-59. To simplify the manufacture of knives, you can cut them from the cloth wide chisel with a cutting stones on the same machine.

Usually the cutter drums mounted on two supports, and it may seem that the reliability of the proposed design of the drum — console — falls. However, if we compare the circumferential force of the electric motor, which is equal to 2.4 kg, with a force of hands employed, which shall be equal to 15-16 kg, with the slightest acceleration of the feed motor will stop. Small engine torque reliably protects the machine from any overload that could cause any damage.

For high quality wood planing is very important the correct sharpening of the knives. At a high angle of taper increases resistance, which leads to overload and overheat the motor, and at small angles sharply reduced resistance of knives, and they quickly tupjatsja. It is very important that the tool has been sharpened equally along the entire length. Holding the knife in his hand, right to sharpen it almost impossible. It is therefore necessary to produce a simple device. It is mounted on two wooden sockets, and the device is self-explanatory. For the correct installation of the grinding angle to the lower socket is attached to the protractor. This device can be used for sharpening other tools.

Fig. 4. Planer drum:

1 — knife 2 — the drum housing.

Fig. 5. Chuck to the spindle.

Fig. 6. Wiring the machine has a reverse switch.

Fig. 7. Device for sharpening knives:

1 — base 2 — hinged bracket 3 bracket mounting knife, 4 — knife.

To perform such operations as the selection of pile, quarters and of every kind, slots, installed lifting table, which can be performed in different ways, depending on available materials. It should be noted that the slots on the brackets of the lift table is not the same machine using abrasive cutting discs. For planing work it is advisable to have a separate table with a more fundamental attachment to the frame, as you may experience vibration during operation, which leads to the formation of ripples on planed surface.

The collection of wood chips and sawdust during the operation of the machine is provided with waste bins, suspended under the Desk top. He is made from dense fabric or imitation leather. The noise level during operation can be significantly reduced if the electrical circuit autotransformer voltage regulator to power at least 250 watts. Works such as sharpening tools, grinding, polishing, sample of quarters and piles can be executed when the power to the motor with a voltage of 70-90 V, the spindle develops this 1300— 1500 Rev/min For longitudinal and transverse sawing, cutting and turning works quite 100-120 V (respectively 1700-2000 rpm). For planing works, 115-127 (2500-3000 rpm). It is clear that depending on the operating mode of the motor is selected and the corresponding feed rate.

If the working conditions the machine noise is of vital importance not imeet the motor supply voltage 127 V. to Include it in the network voltage of 220 V is impossible, as it quickly overheats and starts “Fresnos”.

Needless to say that the work on the proposed machine requires strict adherence to safety rules. So, on the disk cutter and the shaving head needs to be fencing around the common type; grinding, grinding and cutting wheels are closed by a frame with plexiglass. Special attention requires the shaving head. Before you start, you need to check the attachment of separate parts, screw connections and sharpening knives. Sharpening — if necessary — should be made only on the back edge of the knife on a special fixture, and in any case to prevent overheating. To avoid violating balancing and occurrence of vibration of the drum knives with details of their attachment are selected so that the weight of one set different from the second weight by more than 5%, Correct setting is checked with a ruler pressed against the working edge of the table. In this cutting edge should be installed at a depth of cut less than 2 mm. After alignment of knives, previously poorly drawn screws to their footprints, the mounting screws are tightened “vtupuyu” starting in the middle.

In all other respects should follow the General rules for the operation of machine tools.

B. POPOV, engineer

Recommend to read NAGS D-6 A happy event — acquisition the garden plot is often overshadowed due to the lack of supply on this undeveloped territory. In such situation I have made with chain sawing machine to... VOLTAGE ± 5% If during the day to measure the mains voltage, the voltmeter each time will be different. This is due to you can enable or disable individual power consumers, changing mode of operation...  (UNIVERSAL MACHINE). Replacement of manual mechanical tools is of great importance not only in manufacturing, but in the home work of the designer-lover, embodies with wood and metal in their designs. Sometimes even the most simple fixture, primitive stanochki significantly speed up the work, facilitate it and to dramatically improve the quality of the product. That is why in recent years an increasing number of miniature machine tools for processing wood and metal, designed for hobbyists and tinkerers.

(UNIVERSAL MACHINE). Replacement of manual mechanical tools is of great importance not only in manufacturing, but in the home work of the designer-lover, embodies with wood and metal in their designs. Sometimes even the most simple fixture, primitive stanochki significantly speed up the work, facilitate it and to dramatically improve the quality of the product. That is why in recent years an increasing number of miniature machine tools for processing wood and metal, designed for hobbyists and tinkerers.