Dear editors! Send a description of simple tools that may be needed in the manufacture of furniture Think it will appeal to many I have it used successfully for years.

Dear editors! Send a description of simple tools that may be needed in the manufacture of furniture Think it will appeal to many I have it used successfully for years.

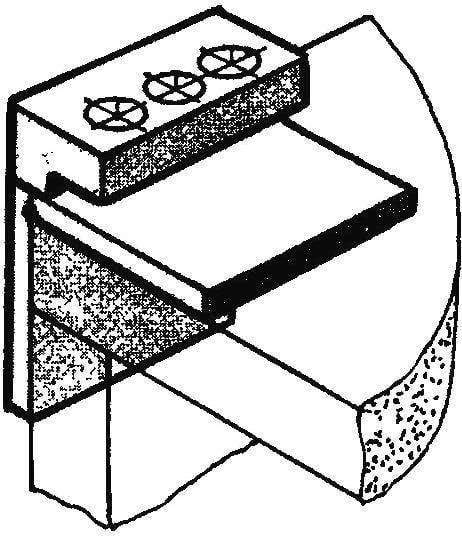

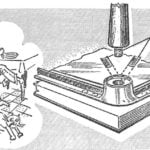

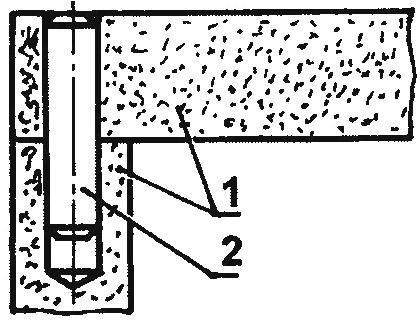

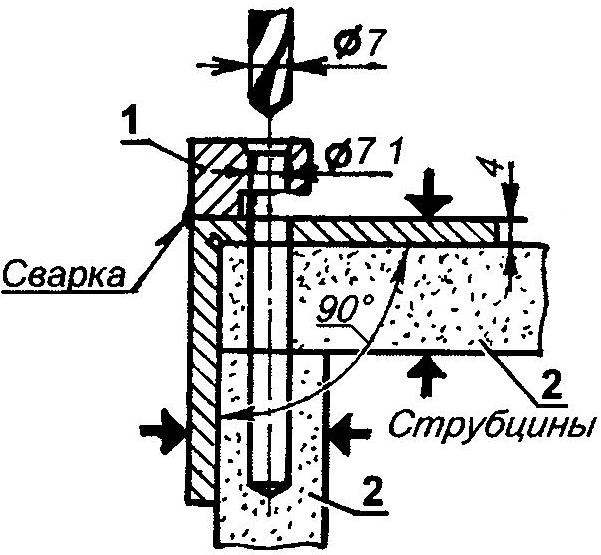

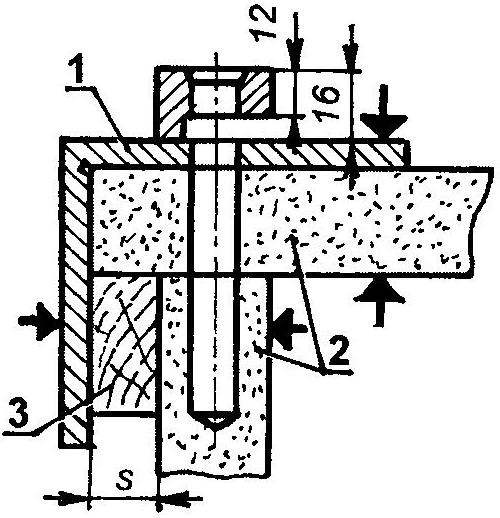

In the procurement of parts for furniture such as cabinets, tables, shelves, chipboard has to take into account the subsequent connecting them at a right angle (Fig.1) by inserting spikes With this purpose, I propose to make drilling holes simple adaptation (conductor) (Fig.2), very convenient and guarantees the necessary accuracy and speed of operations, the Conductor segment consists of a steel angle (for example, 40x40x4) with milled inner sides at a right angle and welded thereto an l-shaped strap. Formed intermediate the groove needed to release the chips from the drill.

The workpiece fixture is mounted one or two clamps (on the drawing the places of their fastening are shown by the arrows).

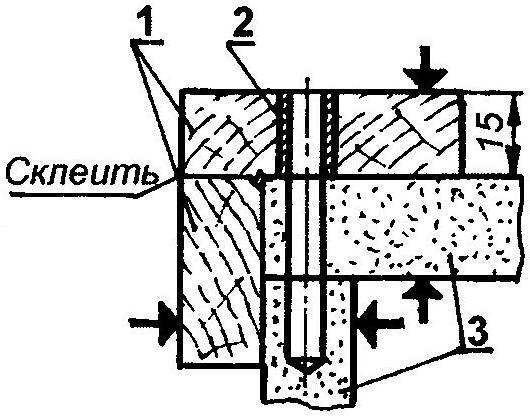

If you can not milled afterwards prepared for the conductor’s area and there are no welding — no problem. This device can be further simplified (Fig.H) replacing metal solid wood (beech, birch, oak) Under the drill bit need only insert (press in) steel sleeve (fit any desired diameter). It is necessary for lesser wear of the conductor.

Fig. 1. Typical connection of wooden panels:

1 — doors, 2 — false tongue (Nagel) with glue

Fig. 2. Fixture for hole drilling:

1 — metal welded conductor from ylca and guide bar, 2 — connect panel (the arrows indicate the place of installation of clamping clamps)

Fig. 3. Wooden jig:

1 — area of the two bonded dies, 2 — tubular metal insert-guide drill, 3 — connect panel

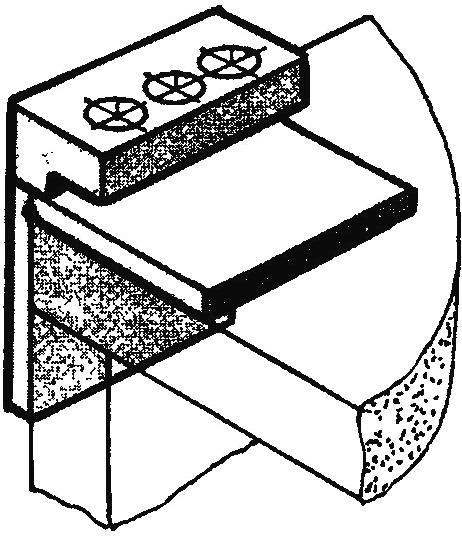

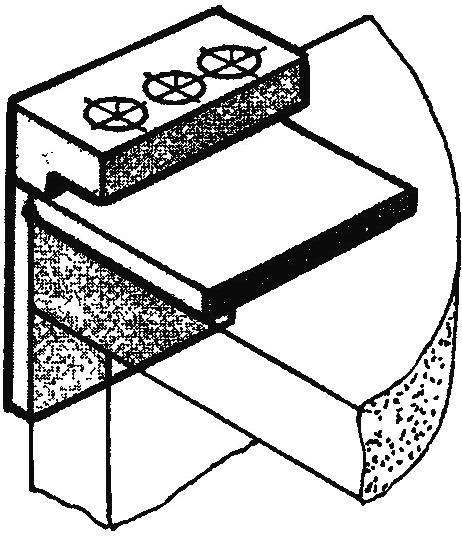

Fig. 4. Ready universal jig with multiple guide holes

Fig. 5. The joint drilling of the panels abutting the wasp:

1 — conductor, 2 — furniture yesterday, 3 — strip-spacer

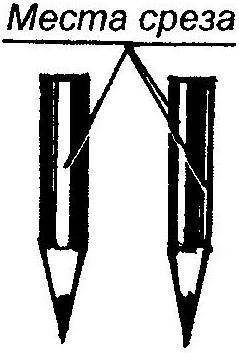

Fig. 6. False spikes (pins) of pencils

In a single conductor to locate several holes (figure 4). Then the device is universal: it can be used to build parts of different thicknesses (16, 18 and 20 mm) with studs of different diameters.

If the connection plates must be done with the indent from the region (with an offset), then the conductor will have the form shown in figure 5.

I recommend the hole in the jig to connect the pieces of chipboard to make a diameter of 7 mm In this case, in addition to dowels (pins) can be used out-of-date pencils-short stacks Only preliminary it is necessary to remove from them the flats from different sides for better adhesion to the plates (Fig.6) It is convenient not to have somewhere to sharpen round spikes, sparingly used discarded material.

For large structures, which will experience heavy loads, it is better to use metal pins.

V. LYASHENKO, engineer, Nizhny Novgorod