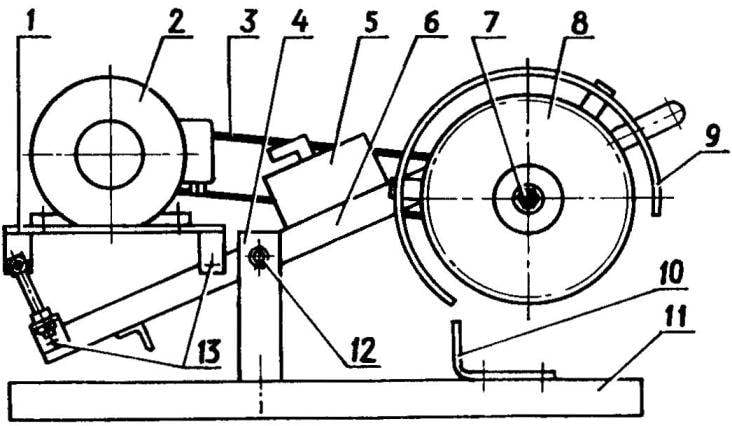

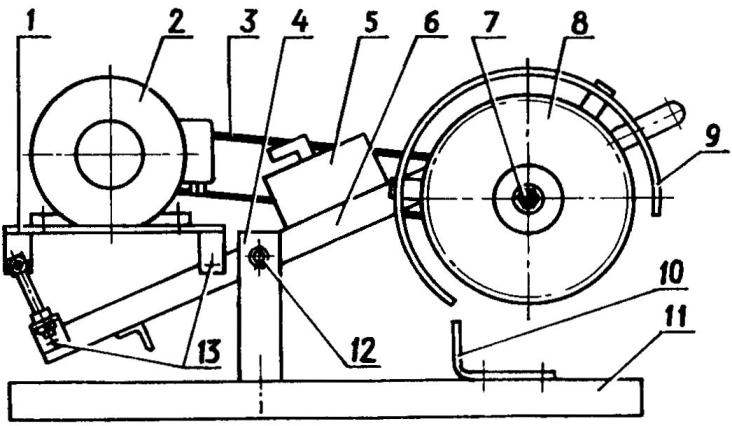

The saw consists of a frame, one end of which is mounted on the drive shaft with saw blade diameter 250 mm, on the other — the motor power of 250 watts. The torque from the engine is transmitted to the shaft wedge belt type A. in the Middle of the frame is placed the casing with the starting equipment.

Frame with all mounted on it with units swinging on balancing the support, which, in turn, mounted on a massive wooden base. This arrangement is advantageous in that the weight of the motor balances the weight of the drive shaft relative to the balancer shaft, so working a saw is tiring.

Saw “cope” with branches with thickness up to 80 mm. Without intensive feeding disk crashes on two-thirds of this thickness. For cutting the remaining third need to turn the branch. Once overcome the entire thickness of the thick branches does not allow low power electric motor. The shear when cutting branches kept focusing, curved steel strip and attached to the base by large wood screws.

Balance circular saw:

1 — area of attachment of the electric motor; 2 — motor; 3 — the drive V-belt (type A); 4 — pole (2 PCs); 5 — switchgear; 6 — frame; 7 — driven shaft; 8 — a circular saw blade; 9 — the plug; 10 — emphasis (2); 11 — the Foundation (Board); 12 — balancini shaft; 13 — bolts M8 mounting pad (4 PCs)

The platform mounts an electric motor:

1 — plate (St3 sheet s3,270×230); 2 — bracket (steel strip 30×4, 2); 3 — cushion (St3, rod d10); 4 — bolt-tensioner (St3, 2); 5 — Bush (St3, 2); 6 — rivet d5 (steel, 4-piece); 7 — washer 10x25x1,5 (2); 8 — cotter pin d3 (2); 9— nut M10 (4 PCs.); 10 — focus bolt-tensioner (steel angle 50x50x4, 2 PCs.)

The frame design is pretty simple: it’s made only four cuts steel angle; welded, front to her cut inch water pipe, wearing a handle of insulating material — handle feed drive.

The most complex knot of my saw drive shaft. It consists of turned speed axis rotating in two double-row radial spherical ball bearings 1205. The bearings are enclosed in an annular housing that is on both sides closed by covers and secured to corners of the frame with four bolts M8. A circular saw blade at the axis is held by two flanges-clutch and pulley — prismatic key.

More simple design of the mount motor. The site itself is a steel rectangle, to which is riveted two U-shaped bracket. The front bracket is attached by M8 bolts directly to the purlins of the frame, and the rear has two bolts, belt tensioners, seated on a common axis — zaspirtovanny the shaft of the steel rod. The threaded ends of these bolts are included in angled abutments, screwed to the frame, allowing you to change the position of the platform (and with it the motor) relative to the frame and thereby adjust the tension on the timing belt.

Drive shaft:

1 — flange (STZ, 2 PCs.); 2 — saw blade; 3 — spacer (St3, 2); 4 — clip (steel, 2pcs); 5 — bearing 1205 (2); 6 — bolt M6 (6 PCs); 7—speed axis (STZ); 8 — pulley (STZ); 9 — washer 14x32x3 (2); 10 — nut M14 (4 pieces); 11 — shear 8x7x22; 12 — bolt M8 (4 PCs); 13 — bearing cap (STZ, 4 pieces); 14 — bearing housing (STZ, 2 PCs.)

Frame:

1 — cross member (steel area 36x36x4, 2); 2— girder (steel area 36x36x4,2); 3 — handle supply of the drive.

Balance shaft (Vs)

Balancer bearing (steel strip 50×5)

Fencing:

1 — protective rim (steel, strip 50×3, L700); 2 — mounting bracket to the frame (steel strip 25×4,2); 3 — rivet d5 (steel, 2pcs)

All other details of the design of the saw is quite simple, for example, the palm branches, so drawing it is not given.

Did not present difficulties and build of the saw. The only difficulty of the installation was to install the frame on the beam axis so that the side of the motor slightly outweighed, and the disc saw in inoperative constantly towered over the base. This is achieved by selection of the position of the frame on the beam axis using the series of holes pre-drilled in the vertical walls of the runs (figures not shown).

It is useful, of course, recall that to operate such a saw is necessary with the strict observance of all rules of electrical safety.

A. MANGUSHEV, Stavropol

Recommend to read DROWN TO CONNECT If the fastening of wooden parts and the screw will be less than their thickness, drill the recess with a diameter of under his hat, and the screw will "pull" to the second part,... TRICYCLE “FRIENDSHIP” (The end. Beginning at No. 10, 1973) In the tenth issue of the magazine, readers got acquainted with the General layout of the three-wheeled micro-car, only "Friendship" design...

Balance small circular saw. After pruning trees in the garden goes into the waste a significant amount of branches of various thickness. Usually they go on the stove. Small branches are easily chopped with an axe, and the larger cut. Hand sawing — it is quite time consuming. To ease the gardening chores, I made a portable circular power saw. Quite light and compact. In addition, it balance, but more on that below.

Balance small circular saw. After pruning trees in the garden goes into the waste a significant amount of branches of various thickness. Usually they go on the stove. Small branches are easily chopped with an axe, and the larger cut. Hand sawing — it is quite time consuming. To ease the gardening chores, I made a portable circular power saw. Quite light and compact. In addition, it balance, but more on that below.