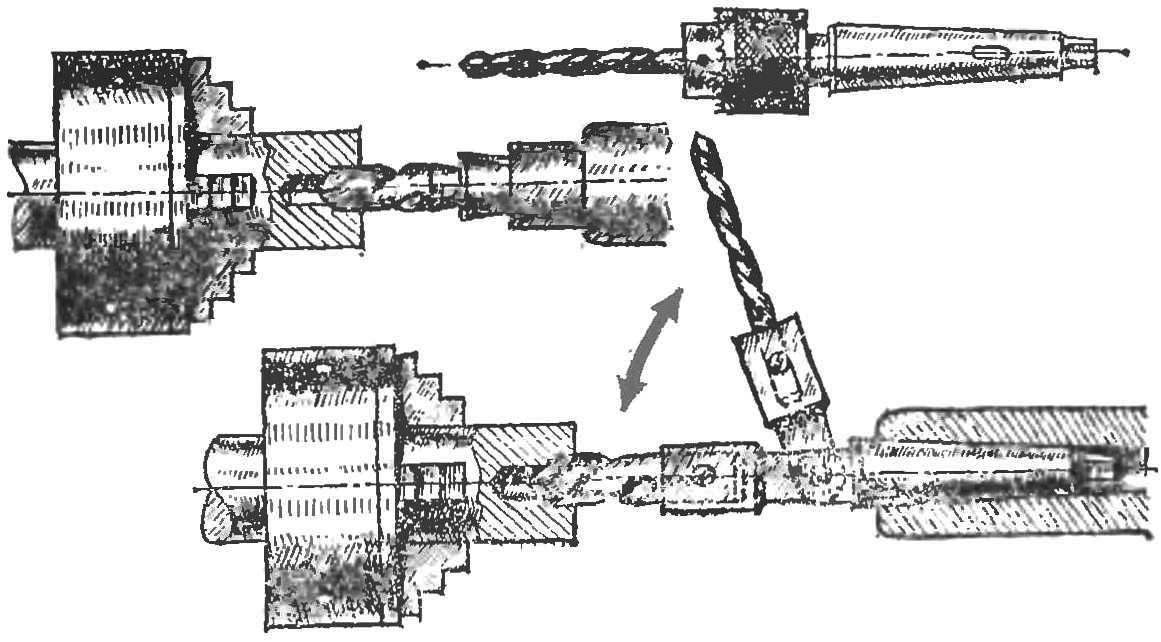

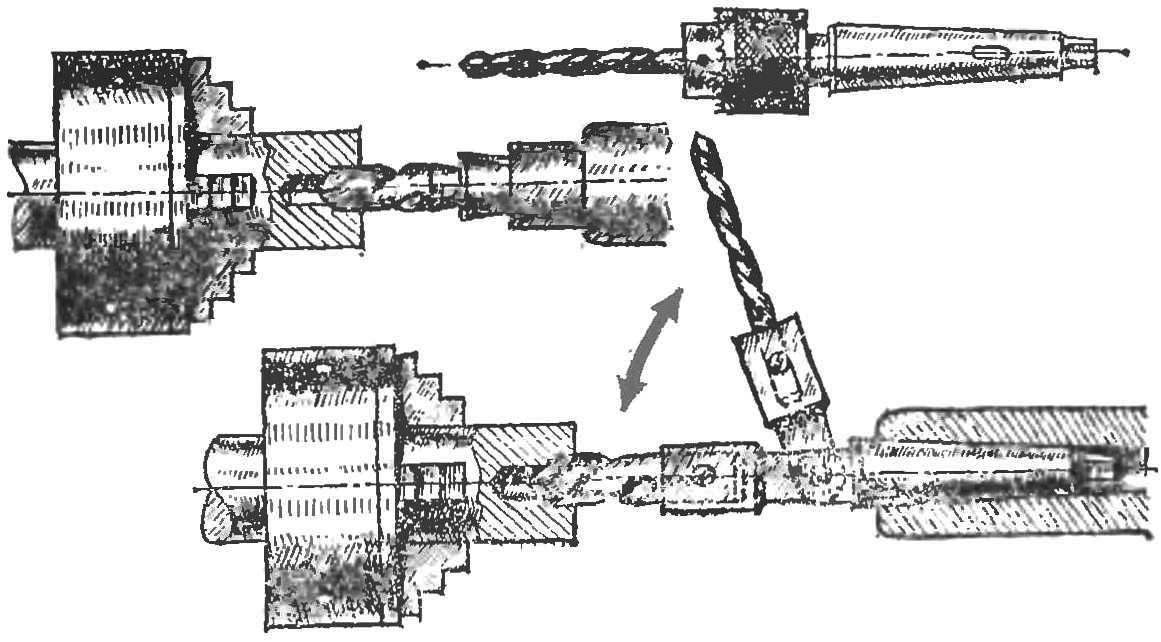

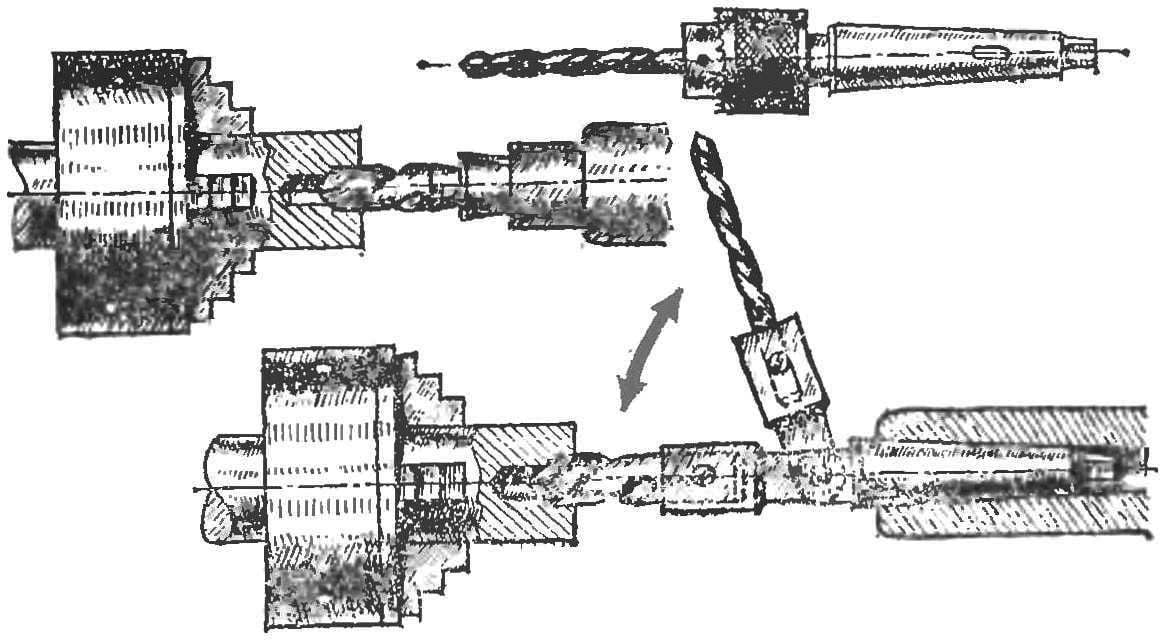

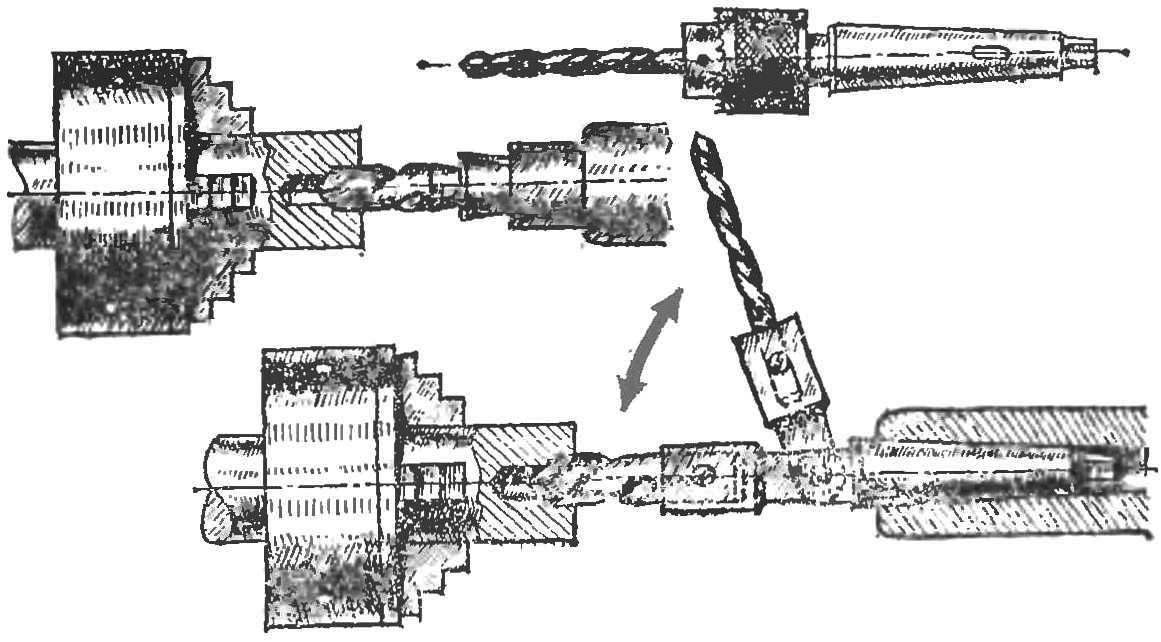

Once instructed the boys to handle on turning the glasses of the part having a stepped hole. The hole is cut, usually in two stages: first inserted into the rear Babin smaller drill bit — drilled the hole, then a tool with a wedge knocked out of the cone and there you insert a different drill bit of larger diameter. Future turners on tapered shank pivotally secured two drill bits. If necessary, Turner enough to let the details of any of them, and the hole is ready. Offer young innovators has allowed the turning shop ahead of time to cope with the order.

Recommend to read

SAVES REFRIGERATOR

SAVES REFRIGERATOR

Anyone who used spokoinym glue, you know that, after mixing with curing agent (with gloves and under the vents: glue is toxic!) after a short time, it thickens and hardens; often, the... WHO IS FASTER?

WHO IS FASTER?

Our magazine has already told about this exciting game, made on the electromagnetic relay (see "M-K" №1, 1976). And today hams instead of contact devices are widely used in their...

Once instructed the boys to handle on turning the glasses of the part having a stepped hole. The hole is cut, usually in two stages: first inserted into the rear Babin smaller drill bit — drilled the hole, then a tool with a wedge knocked out of the cone and there you insert a different drill bit of larger diameter. Future turners on tapered shank pivotally secured two drill bits. If necessary, Turner enough to let the details of any of them, and the hole is ready. Offer young innovators has allowed the turning shop ahead of time to cope with the order.

Once instructed the boys to handle on turning the glasses of the part having a stepped hole. The hole is cut, usually in two stages: first inserted into the rear Babin smaller drill bit — drilled the hole, then a tool with a wedge knocked out of the cone and there you insert a different drill bit of larger diameter. Future turners on tapered shank pivotally secured two drill bits. If necessary, Turner enough to let the details of any of them, and the hole is ready. Offer young innovators has allowed the turning shop ahead of time to cope with the order.

Once instructed the boys to handle on turning the glasses of the part having a stepped hole. The hole is cut, usually in two stages: first inserted into the rear Babin smaller drill bit — drilled the hole, then a tool with a wedge knocked out of the cone and there you insert a different drill bit of larger diameter. Future turners on tapered shank pivotally secured two drill bits. If necessary, Turner enough to let the details of any of them, and the hole is ready. Offer young innovators has allowed the turning shop ahead of time to cope with the order.

Once instructed the boys to handle on turning the glasses of the part having a stepped hole. The hole is cut, usually in two stages: first inserted into the rear Babin smaller drill bit — drilled the hole, then a tool with a wedge knocked out of the cone and there you insert a different drill bit of larger diameter. Future turners on tapered shank pivotally secured two drill bits. If necessary, Turner enough to let the details of any of them, and the hole is ready. Offer young innovators has allowed the turning shop ahead of time to cope with the order.