Therefore, in order to implement the conceived idea, before you begin, make a simple device that is able not only to simplify, but also much to improve the quality of the finished product, but also save time.

The primary method of joining parts homemade furniture on thorns. And how exactly marked and drilled them for the holes, the appearance of the product depends not less than the quality of the decorative finish. The figure shows a typical joint of two panels. One of them, vertical holes for the spikes should be at mid-thickness, while the horizontal is exactly the same distance from the edge. The holes must be strictly parallel.

A special device for drilling holes for the spikes allows to perform this operation literally in a matter of seconds, and without any preliminary marking. The “secret” lies in the fact that the compressed clamps panels are drilled sequentially through the guide-conductors.

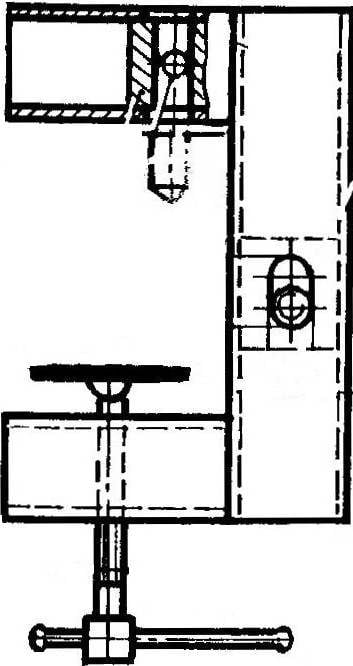

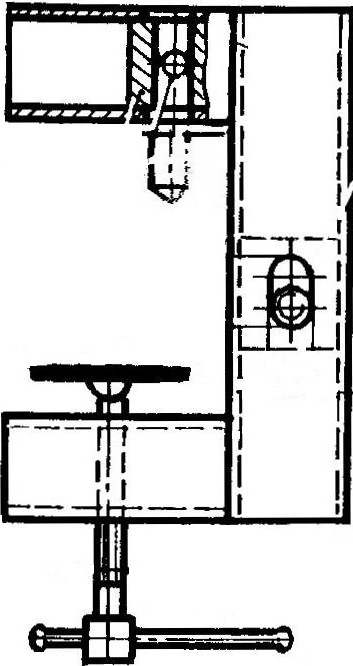

Fig. 1. Jig for drilling:

1 — clamp (steel profile 25 x 25 mm), 2 — conductor (steel, 2 pieces), 3 screws M8, 4 — screw combination (4 PCs.).

For the processing of panels of different thickness in the fixture, adjust the position of the guides.

Fig. 2. A typical connection of the panels on the spines.

The basis fixture is a U-shaped clamp, welded hollow steel profiles of square or rectangular cross section. In the cavity top and side rails are inserted, can move in with minimal clearance. With their help, and you are drilling into panels. Two M5 screws through washers provide grip on any conductor in the desired position defined by the thickness of used panels.

To work with the device is very simple: at first by means of clamps the boards are held together so that their front and side edges match, then enhance the fixture, if necessary, adjust the position of the conductors and drill one hole in each panel. Moving the fixture to another location along the clamped edges of the panels, drill the next few holes, and so on. The resulting holes after rotating the panels should be the same regardless of their number and the distance between them.

M. ANDREEV

Recommend to read WELDING… WATER I'm a longtime subscriber of your magazine, use a lot of printed in it. I especially liked the article "Fire... of water", published in "M-K" № 7, 1980. The description made the cell,... THE AIR IS PARTICLE BOARD Who said that the furniture in the nursery, or, indeed, in the room of a teenager must be the same as half of adult? A cottage or summer house in the garden? Yugoslav journal...  Starting to manufacture handmade furniture, a home master, most do not have the skills of carpenters professionals are faced with two main problems (not counting, of course, of the shortage of materials and tools) — how exactly to cut and how exactly to drill! Indeed, those who master these seemingly simple operations, it becomes on the shoulder almost any design, but… the skill takes time, and burned once, some often give up before they have lost all desire to make.

Starting to manufacture handmade furniture, a home master, most do not have the skills of carpenters professionals are faced with two main problems (not counting, of course, of the shortage of materials and tools) — how exactly to cut and how exactly to drill! Indeed, those who master these seemingly simple operations, it becomes on the shoulder almost any design, but… the skill takes time, and burned once, some often give up before they have lost all desire to make.