Rust metal, faded over time, brickwork, lost look painted surface… In all these cases is taken sandpaper or a metal brush — and stop! In the direction — is the last day! The lion’s share of tedious work in the clean-up should be given to the mechanism of the electro.

Rust metal, faded over time, brickwork, lost look painted surface… In all these cases is taken sandpaper or a metal brush — and stop! In the direction — is the last day! The lion’s share of tedious work in the clean-up should be given to the mechanism of the electro.

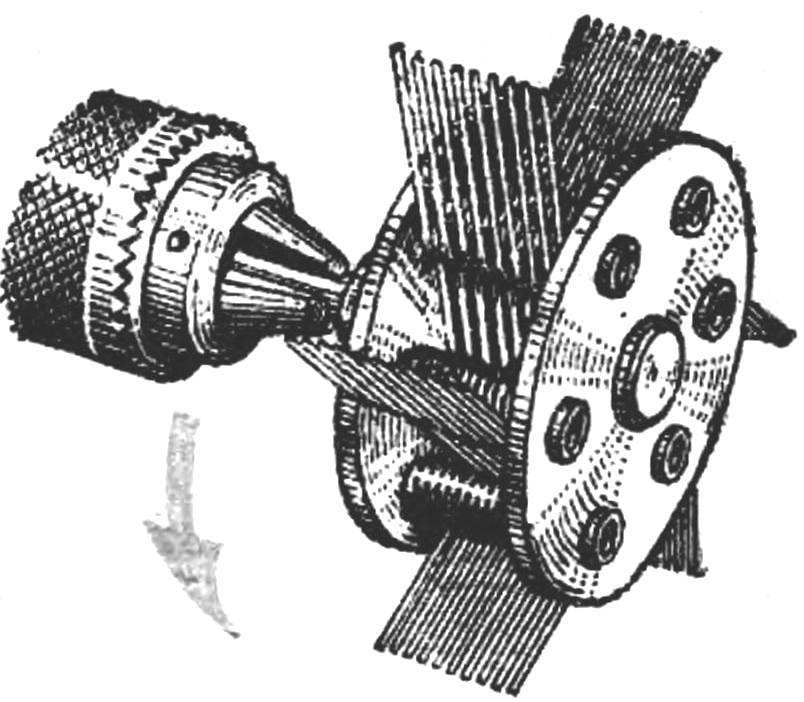

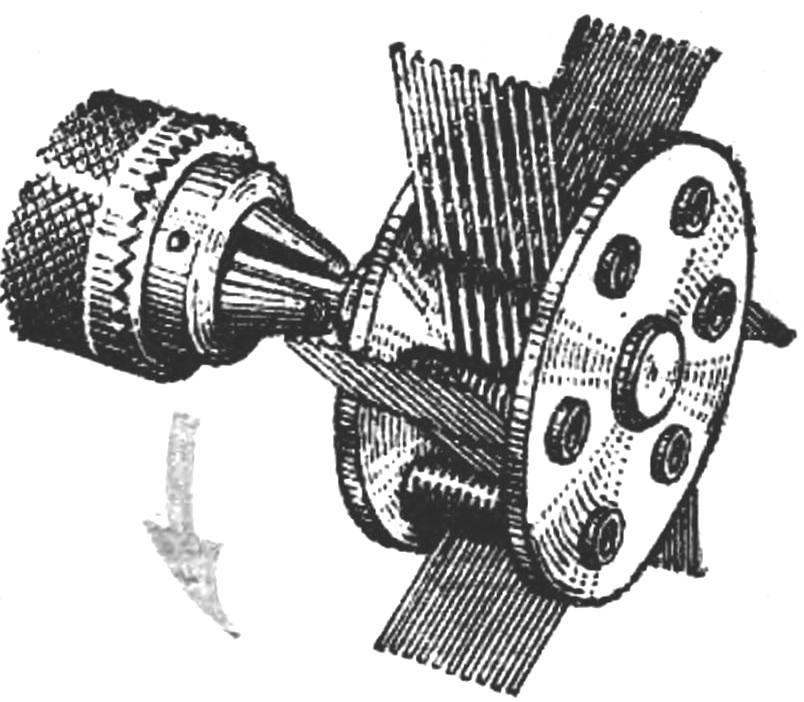

Half of the mechanism in front of you, if you have a power drill. Any alteration she doesn’t need. The other half improvised.

The way the brush is simple (see figure): an axis — bolt special form planted two steel discs. Landing square neck bolt, so the torque is securely transmitted to the CDs. Between them — spacers, machined from lengths of steel pipe. Each sleeve carries a number of freely located on it “bristles” of elastic steel wire. Wire chopped into lengths of 145-147 mm, and those bent to form a loop under the bushing. External long end of the “bristles” work, internal — only for fixing it in position. When there is a sweep, the inner ends are pressed against the front running sleeves and provide the “stubble” stiffness.