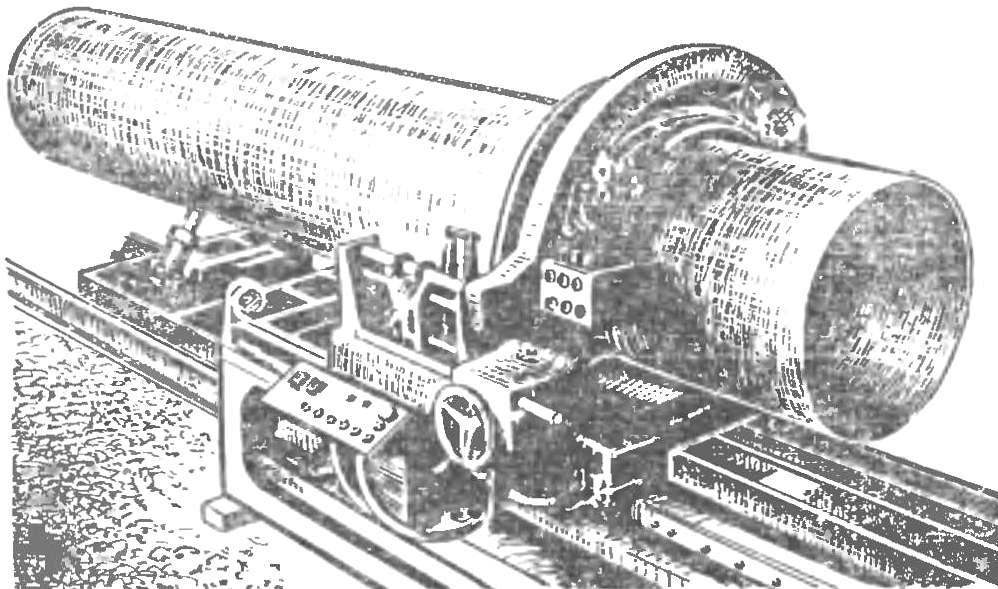

The working head of the machine, snake obviouses his bracket around the pipe, produces a hissing blue tongue of flame. Licking the metal, as if it bites into him and now burns through, slowly slitting thick wall pipe.

The working head of the machine, snake obviouses his bracket around the pipe, produces a hissing blue tongue of flame. Licking the metal, as if it bites into him and now burns through, slowly slitting thick wall pipe.

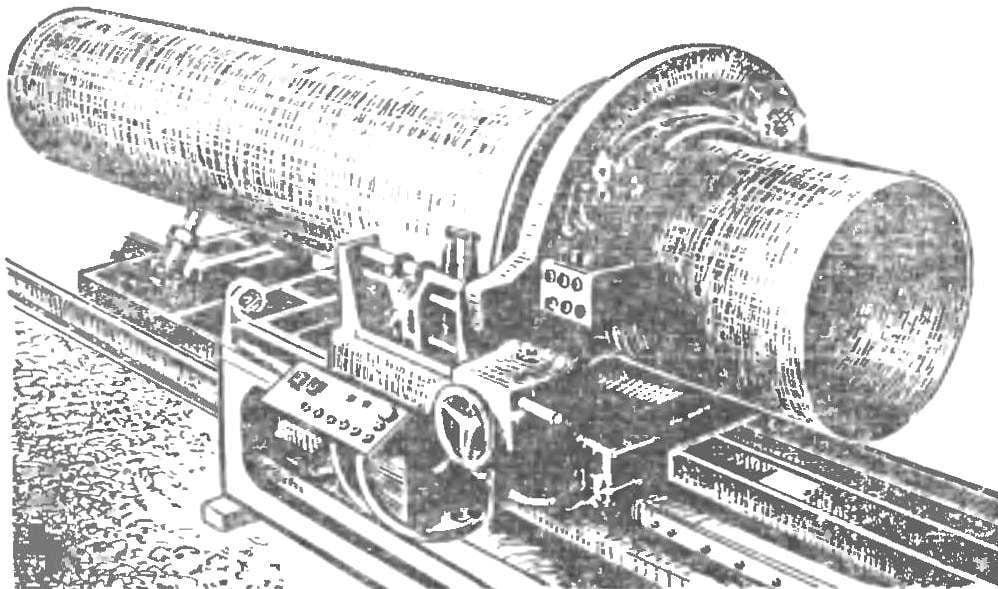

Cutting torch — not new: it has long been widely used everywhere along with welding. However, in the new machine, named “bug-2”, the cutter rotates around a stationary pipe, at the same time moving along it, thus making it possible to “figure” cutting the cylindrical body.

Early for shaped cutting of the pipe had to perform a rather intensive range of support work: to lay out pipe, design and make templates, the”pattern” and conduct other preparatory operations.

“Bug-2” — machine for gas cutting of pipes.

Now on the machine “bug-2” operator panel immediately without the use of copiers to do not only direct, but also oblique, complex, drawing the sections of pipe billets. The drive of the cutting device ensures a continuous regulation of the speed and direction of movement of the main working bodies. It not only allows you to cut with optimum speed, but also ensures a good quality cut surface. Thus the required speed of movement of the cutting torch relative to the pipe is set by the operator directly in the process. And setting of the machine is not connected with assistive devices, does not require any significant investment of time.

Mechanized and supply pipes to the machine and transports the cut billet: these operations are performed using self-propelled carts.

Simultaneously with the cutting “bug-2” removes the chamfer for welding.

In General, the introduction of this machine considerably reduces the complexity of manufacturing and increases the quality of parts of pipelines with diameter from 350 to 1020 mm and wall thickness up to 20 mm; excludes ancillary operations and devices for shaped cutting; increases productivity 2 to 4 times compared with manual gas cutting.