This hang glider in appearance very simple. Outwardly, it resembles a paper dove. But behind the apparent simplicity hides a precise calculation.

This hang glider in appearance very simple. Outwardly, it resembles a paper dove. But behind the apparent simplicity hides a precise calculation.

To build the necessary dry straw, balsa or foam, lime, steel wire Ø 0,6—0,8 mm, thread, a thin film or micuenta paper for gluing of load-bearing planes, model aircraft rubber, glue BF-2, or enamel.

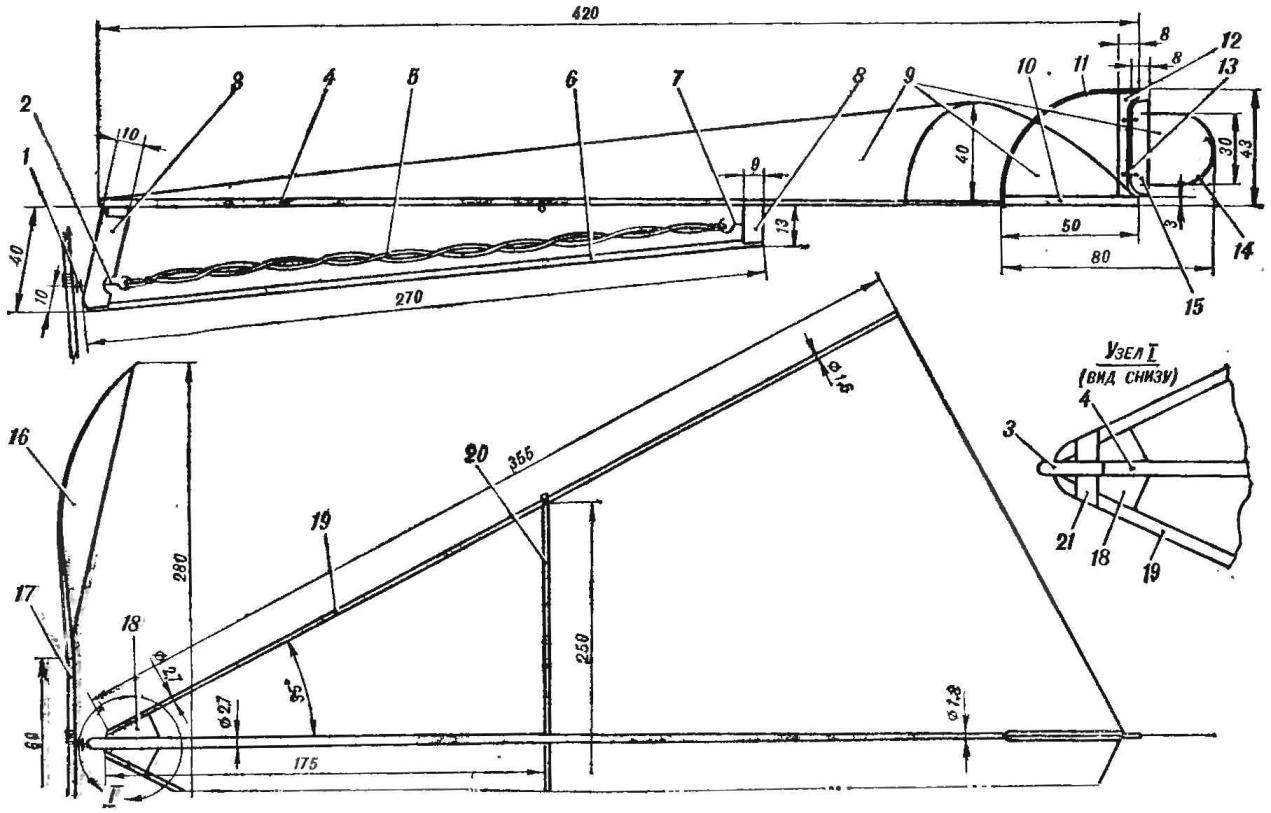

The main part of the frame consists of three thatched cross members from Central laterally at an angle of 35° away the other two. Staple them together with balsa triangles. The bottom of the two balsa uprights attach to the Central Solomin another to increase rigidity of the frame and the rubber motor.

In the bottom of the front struts make a hole for the axis of the screw.

For strength, reinforce the frame model of the cross culm, attaching it to the three main. All joints complete with yarn and glue.

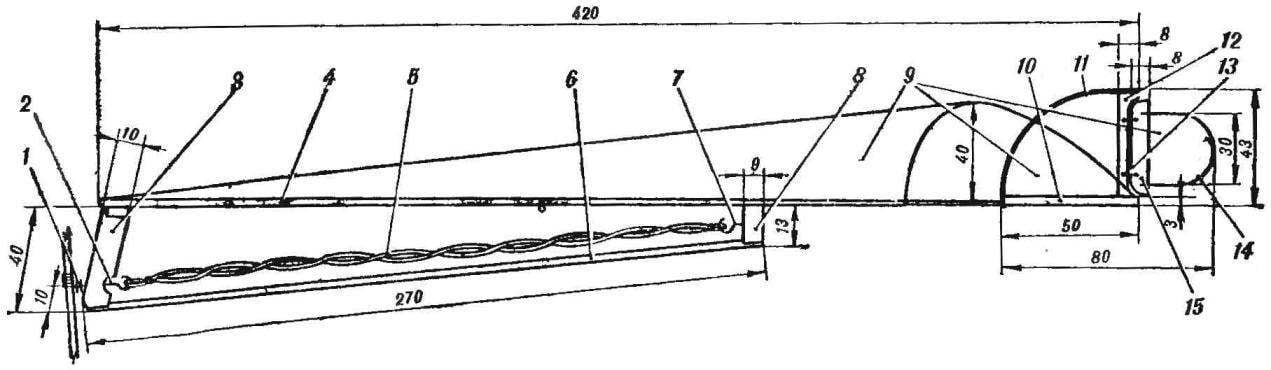

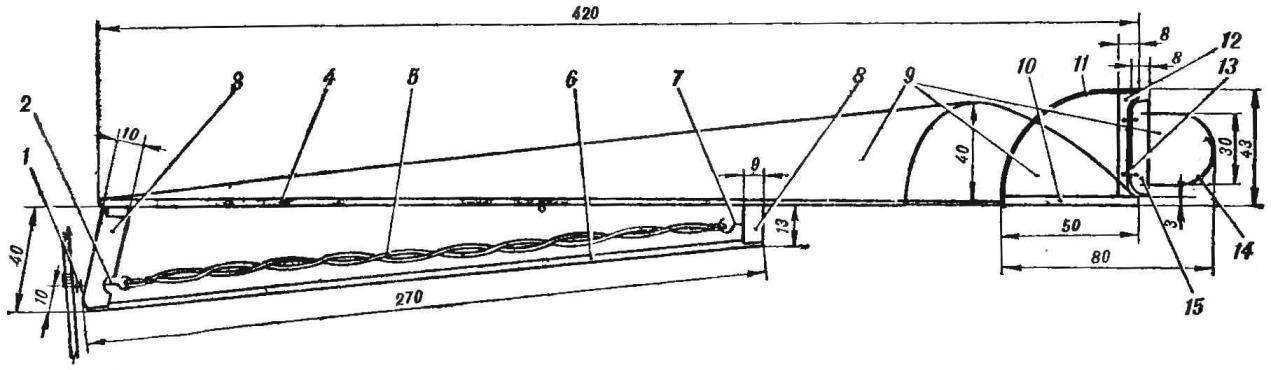

Fig. 1. General appearance:

1 — washer (celluloid), 2 — the axis of the screw (wire Ø0,8), 3, — front Desk (balsa 4X10X40), 4 — Main beam (straw), 5 — a rubber motor (four rubber thread), 6 — lower beam (straw), 7 — hook (wire Ø0,8), 8 — rear rack (balsa 3x9X13), 9 — a close-fitting (aircraft modeling paper), 10 — the bottom of the keel (balsa), 11 — Kiel, 12 — edge of the keel (Linden), 13 — string loops, 14 the rudder, 15 the edge of the helm (lime), a 16 — screw 17 — the propeller hub (straw), 18 — area (balsa), 19 — lateral beam (straw), 20 — cross beam (straw), 21 — Klondike (balsa 2X7). On node I, item 6 not shown.

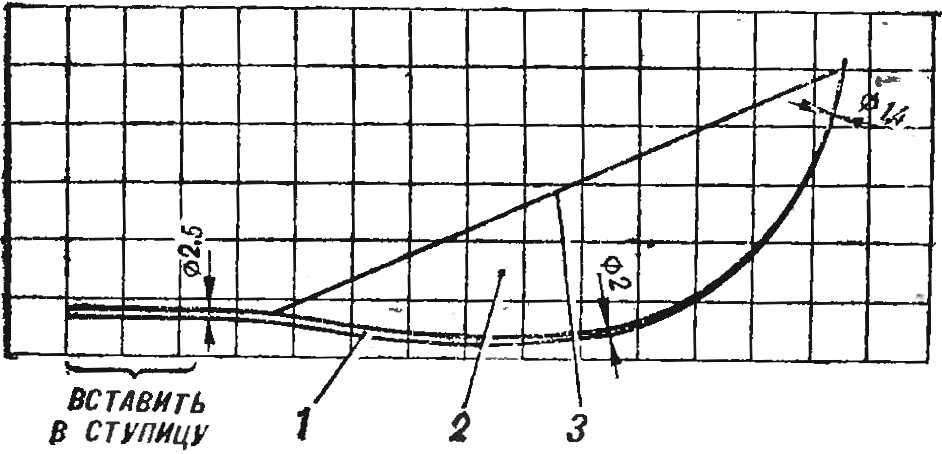

Fig. 2. The design of the blades:

1 — straw, 2 — paper, 3 — thread.

The keel will attach to the balsa plank that is installed on the end of the Central straw. The node consists of two parts, one of them rotatable, connected to the stationary filament loops.

Screw made of straw. It consists of a hub and two inserted in her blades. The axis curved at a 90° angle, insert into the hole in the hub and attach the thread. Axle put on celluloid washers. The blades Flex over the fire.

Make a rubber motor of four strands of round cross-section and in a free state they have a little SAG. Tight frame it is necessary to perform so that the paper SAG in the end by 40 mm.

A hang glider flies and have not started the motor. To model well planned, utilite nose, attaching to the end of the Central straw a piece of clay.

Tighten the rubber motor at 160— 200 rpm. Before starting the glider remember to lubricate the axle and bearings castor or motor oil.

A. DEMIDOV, Stavropol