These two even look something like a high-performance tool developed by young innovators Dmitrov excavator plant. Brings them closer, and purpose: making large-diameter holes. The difference between constructive because they are intended for use with different materials.

These two even look something like a high-performance tool developed by young innovators Dmitrov excavator plant. Brings them closer, and purpose: making large-diameter holes. The difference between constructive because they are intended for use with different materials.

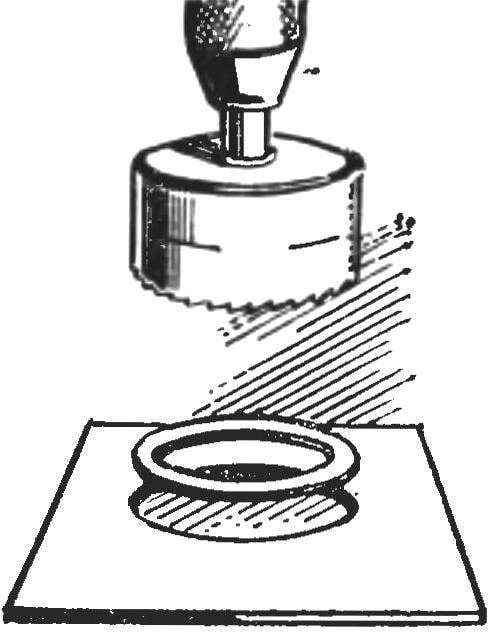

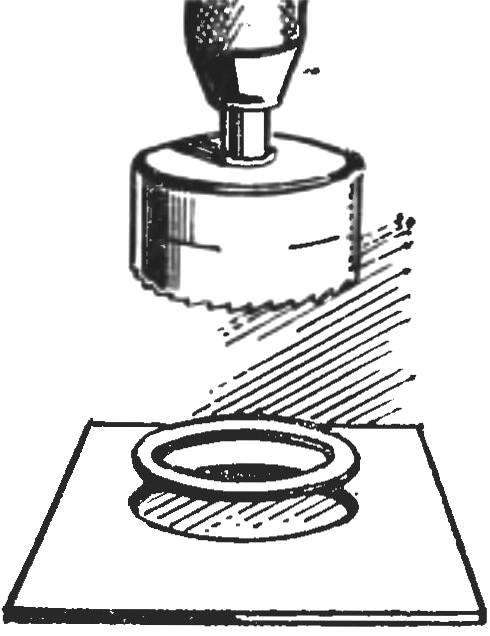

One that consists of half-cylinders (see Fig.), designed for cutting rubber rings Ø 15-120 mm sheet with a thickness of 5-12 mm. One of the working halves of this kind of cutters scalloped edge passes the outer edge of the future of the ring, the other cuts the inner circle. The tool is not dull, and to get a good quality edges, under the rubber workpiece is placed a wooden Board.

Both the saw blade of a half-cylinder mounted on the mandrel with Morse taper No. 5. This allows you to perform working operations, securing a cutter on a conventional radial drilling machine.

Depth of cut rubber gaskets:

1 — cone of the mandrel, 2 — external poluotoka a saw blade, 3 — interchangeable internal poluotoka

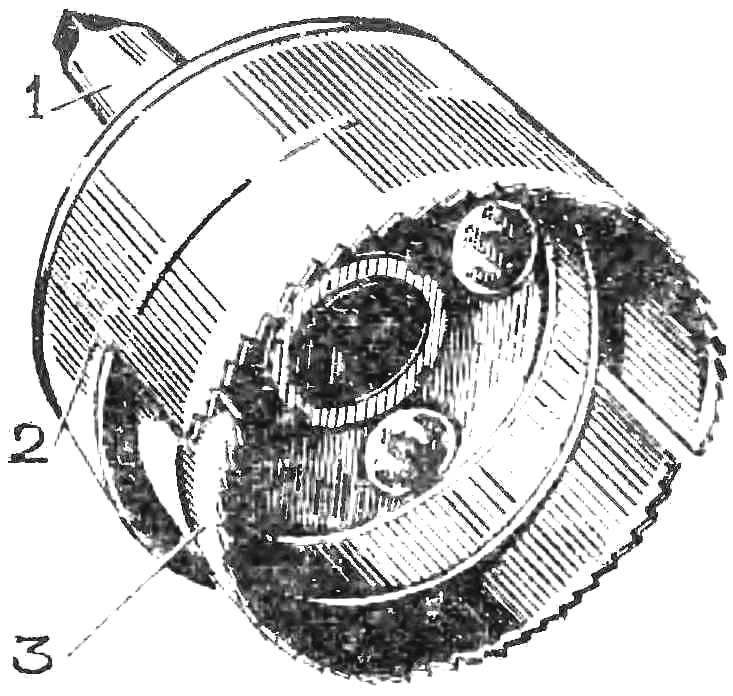

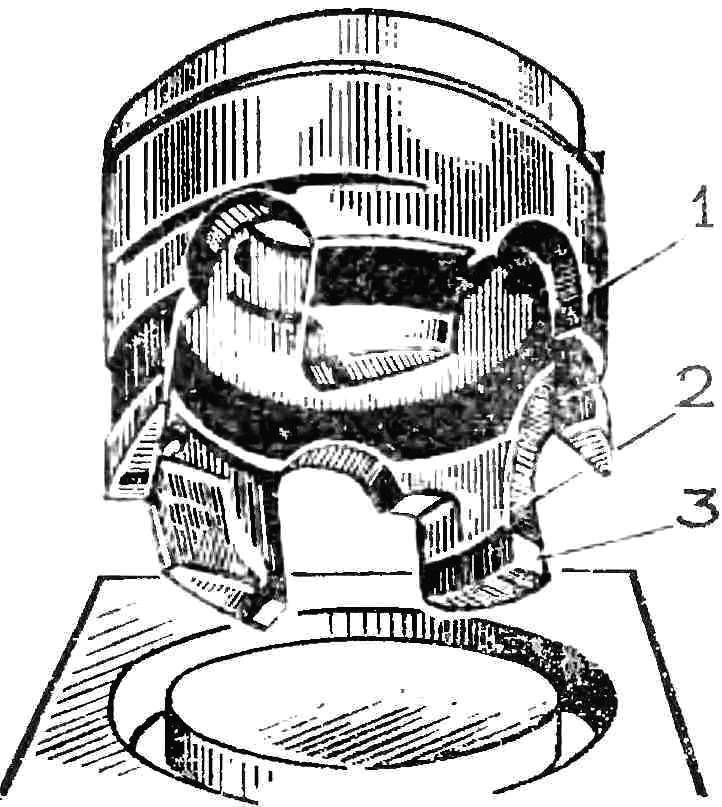

The annular drill bit:

1 — housing (bushing), 2 — holder, 3 — carbide insert

The second tool is not that other, as the ring drill bit for cutting hole Ø 90-120 mm in plate material. Usually first drill a small hole — as far as the diameter of the existing drill — and then rassverlivajut and chiseled his cutter in several passes. The annular drill bit reduces the number of operations to two as it allows immediately to make a hole the required size. The drill consists of a housing made in the form of a sleeve, the drive pin with the groove on one side and brazed cutting plates made of hard alloy.