Line — usually wooden, of a width of 30 to 50 mm, the length depends on the size of the glass. The ribs should be otfugovany and one of them is removed chamfer.

Gon — too wooden, he’ll need to check for rectangular-STI cut into pieces.

Meter — better than metal, in the form of roulette — to determine the size of the glass.

A knife with a blunt blade to work with putty. Easier if the end is cut at an angle 60-70°.

A massive chisel with a wide blade commonly used for driving nails or studs sliding movements on the glass, which reduces the risk to break it, compared to, for example, with a hammer.

Hammer, pliers, wire cutters, pliers.

RATIONAL CUTTING OF GLASS

With proper cutting, it turns out less waste and yield more business pieces. Let us consider some concrete examples.

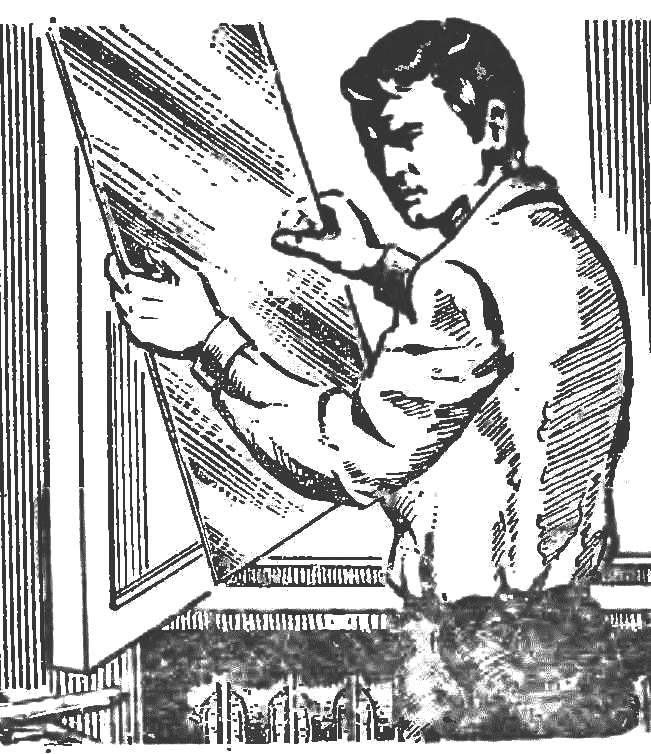

R and S. 6. The insertion of glass folds of the frame .

From sheet glass size 1200X 600 mm should be cut into working blanks of size 500 X 300 mm. With an efficient cutting (see Fig.) we’ll have four glass the right size and balance with a size of 200X600 mm, which can also go into business. The total length of the cut will be at the same 2200 mm. Ill also reveal to give the desired four blanks and useless the rest of 100X1200 mm, and the glass cutter will be 2700 mm by 500 mm and more.

When another sheet size 1200X800 mm is required to obtain 300X700 mm glass, remnants, too, can be running three stelsel and the rest 500ХСС0 mm piece also width of 200 mm.

If the preliminary layout is necessary to ensure that the resulting blank overlaps the folds is not more than 3/4 of their width, that is, between the edge of the glass and wood remained a gap of at least 2 mm. for Example, if the measurements are in the fold 700X1000 mm, the glass to insert must be 697X997 mm: then it will freely fall into the folds and will not crack under the pressure of swollen wood.

For glazing large surfaces — for example, the veranda — the first cut all the blanks, proolifit or to paint over folds, to prepare putty and then start inserting.

CUTTING should only be carried out on line and only on a dry and clean glass.

Diamond glass cutter is clamped thumb and forefinger on the hammer, on which (or the handle) has a label indicating that it must cling to the lineup. On the glass cutter press lightly, no more than a pencil and trace the cut determine the correct tilt of the instrument and lead him on. The glass should be thin, colorless line. Smooth, with a characteristic crackling sound confirms that the diamond is cut correctly. The wide scratch and white glass dust on the trail indicates that a wrong slope of the instrument or too much pressure on him.

Before reaching the end of the cut at 3-5 mm, push weaken to a sharp descent from the glass not to damage the cutting face of the diamond on the edge of the window. Is not allowed and re-cut on the same pine — better then carefully break off unevenly deviated edge.

Roller steklorez hold perpendicular to the plane of the glass. The pressure applied should be greater than that of diamond, so that clearly visible white line

If the glass is scratched right, just enough to lift it at the ends of the cutting line — and it smoothly and easily break in two. If not — combine a cut with the edge of the table and gently press down on the hovering part. Experienced glaziers with the same purpose tapping with a hammer on the bottom of the glass cutter on the cutting line.

THE PREPARATION OF PUTTY

It can be of two types: thick doughy for smearing after packing and fastening of glass and semi-fluid, loose — for applying pre-bed layer on uneven folds before laying glass This technique is called glazing on double putty.

The putty should be plastic (roll of her stretched and purifies until you break, bad breaks without stretching): soft, easy to hit folds; adhere well to glass and wood, but not to your hands or the knife, after which the surface should remain shiny, without any roughness. Properly cooked

R and S. 7. Fabrication and clogging of the wire studs .

Naya putty frost and heat resistant, will not crack and is not far behind, reliable is not less than 10 years.

The procedure for its preparation is as follows. In sheet steel, plastics, plywood poured slide dry tonkosejanogo a chalk, make a funnel from the top. It poured linseed oil and begin stir stick, spatula-Veselka or a spatula, gradually add a chalk before reception of a necessary consistence. The density at which the stirring is no longer possible, shows that we have got putty for the bedding layer. She became even thicker, add some additional layer of filler, thickness of 10-12 mm and roll it with your hands obtained kom the dough until it stops sticking to the hands and absorb it all in. Well viitana putty should be homogeneous, without chalk or drying oil layers. At this stage and check the quality of the putty with a roller.

When you add a dry building paints they are mixed with chalk, grated pre-diluted with linseed oil.

Keep the dough in a tight plastic bag. Slightly hardened kom knead with your hands, and the solid is crushed, add the oil and roll out again.

To produce 1 kg of ordinary chalk putty will need an average of 220 g of linseed oil and 820 g of chalk. If it prepare on iron oxide, the ratio of the following components: linseed oil 150 g, 700 g of chalk, minium 170 g.

Consumption: depends on glass thickness and size of the folds. 10 linear metres folds size 10×15 mm goes chalk putty 1.5 kg (minimum 1 kg); with 10X 20 mm up to 15X15 mm — 1.6 kg (2.4 kg); with 15X20 mm — 2.4 kg (3.5 kg). Bound bead, set in putty, the consumption is reduced by almost half.

THE CONSOLIDATION OF THE GLASS

Hairpins and nails hammer in 200-300 mm, and the window is 200 mm, and so they entered the wood parallel to the plane of the glass, holding him, not udaliaias to the edge, otherwise the glass will crack.

Studs glass fix. In his left hand holding a spool of steel wire, the thumb of the right press to the sting of a chisel and bent at right angles to the end of a length of 17-20 mm. Then the wire sticks to the glass and sliding movements are driven into the wood so that the bending place has crossed the border of the future layer of putty. Enough now two or three times to swing the wire to it broke off at the bending place, leaving the pin in the cover.

Instead of wire studs sometimes used a flat triangular fasteners, cut from corrugated iron, bent it’s also a chisel.

APPLYING PUTTY

The plaster folds performed as follows. In the left hand take a lump of putty, right — knife; they cut off the test strip, put a leaf and pressed into him, tightly filling and leveling with a knife until obtaining a layer of the same width. Squeezed out at the edge of the seam excess, cut it with a knife and menaut back to kom. The applied layer should cover the fasteners, otherwise it will begin to rust and the binding will run red streaks.

R and p. 8. Glass fastening: A is correct, B is wrong .

GLAZING ON DOUBLE PUTTY

Such an implementation more complex, but more durable. Folds applied on prepared bedding layer of semi-liquid dough up to 3 mm thick, the glass is placed on it and pressed so that the putty stuck to it and filled the gaps between it and the folds. Then the glass is fixed now solid on top with putty. The excess coating on both sides, cut it with a knife, and the surface completely level.

BEADINGS

It’s thin strips, as a substitute for the attachment of the glass and even clay. They give the covers a more aesthetic appearance, increase their durability and reduce the complexity of the glazing. They are fixed to folds nails or fine screws with a pitch of 300-400 mm.

In unheated rooms the dry perform inserts: press to

glass beadings and kill them. The heated glass is first superimposed on the bedding putty and top bead attached. You can do beadings to put on a layer of bedding putty and glass covers on both sides, increasing the guarantee of integrity of the glazing. After drying, the coating binding with the bead color.

Fig. 9. Coating glass with a knife .

However, the meaning of the sealed glazing is lost, if there are large cracks in the remaining parts of window frames or doors. Instead of zakonopacheny or wall paper you can fill them netwareuser filler, which is easily removed and leaves no residue on the paint. It is well-known playdough. However, where do we get it in the right amount? It is better to prepare neverdead putty myself. This will require 6 ppm of grease, 14 parts spindle or solar oil, and sifted chalk to desired thickness. The old grease in the bowl or saucepan, put on low heat and once it becomes completely liquid, intensively stirring slowly, add oil: is obtained a viscous mass. After cooling it is poured chalk and roll out with hands to desired thickness. Roll out of such putty cushions, put them one at a time to the slit and pushed inside.

This careful sealing not only eliminates the leakage of heat from the room, but even fogging of the Windows.

A. SHEPELEV, civil engineer

Recommend to read Tu-22 The Tu-22 was designed to replace the Tu-16. The design of the new aircraft under the symbol "105" was initiated in the Tupolev 15 August 1955 and August 1957 was completed construction... NOT LEVER AND SWITCH The development of the garden or suburban area, many owners have to start with providing it with water. Since this problem started and I. The water in the area lies relatively close to...  Remember: it was not cold in your house last winter? Do not rush to blame the heating system, even if it furnace: victoriat room can and Windows. Check to see if the putty on the frames and I wanna see if she cracks through the thin slit between the glass and the wood heat is rapidly going out of the house and cold air is not less noticeable comes inside. The measurements indicate, through window and door openings can dissipate up to 2/3 of the generated heat-generating appliances heat. That’s why remaining before the real cold days are useful to restore the integrity of window glazing. As describe in detail. Our tips will be useful for individual developers, and those who want to make a greenhouse or glasshouse.

Remember: it was not cold in your house last winter? Do not rush to blame the heating system, even if it furnace: victoriat room can and Windows. Check to see if the putty on the frames and I wanna see if she cracks through the thin slit between the glass and the wood heat is rapidly going out of the house and cold air is not less noticeable comes inside. The measurements indicate, through window and door openings can dissipate up to 2/3 of the generated heat-generating appliances heat. That’s why remaining before the real cold days are useful to restore the integrity of window glazing. As describe in detail. Our tips will be useful for individual developers, and those who want to make a greenhouse or glasshouse.