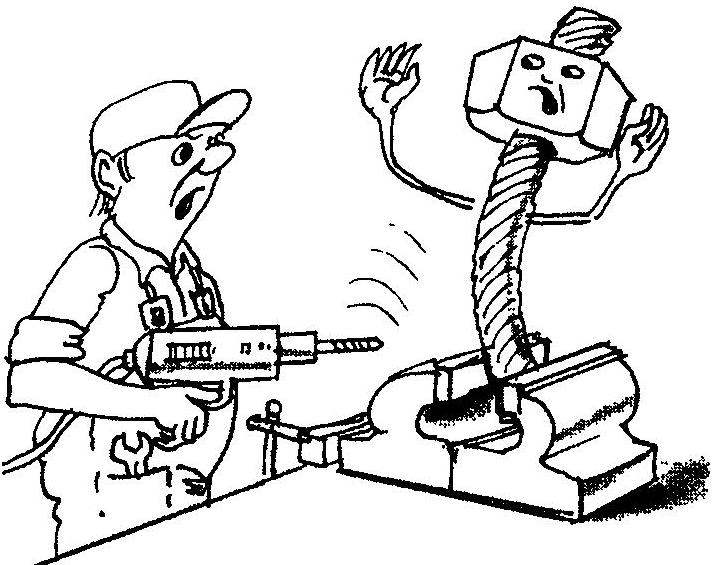

Billet parts designed for machining, not be displaced, to rotate, to vibrate or deform under the action of the cutter. In the process of manual handling (this applies primarily to the production of their own designs) can be used multiple ways of fastening plates, cylinders or tubes In the pictures are some of the options appropriate devices.

Billet parts designed for machining, not be displaced, to rotate, to vibrate or deform under the action of the cutter. In the process of manual handling (this applies primarily to the production of their own designs) can be used multiple ways of fastening plates, cylinders or tubes In the pictures are some of the options appropriate devices.

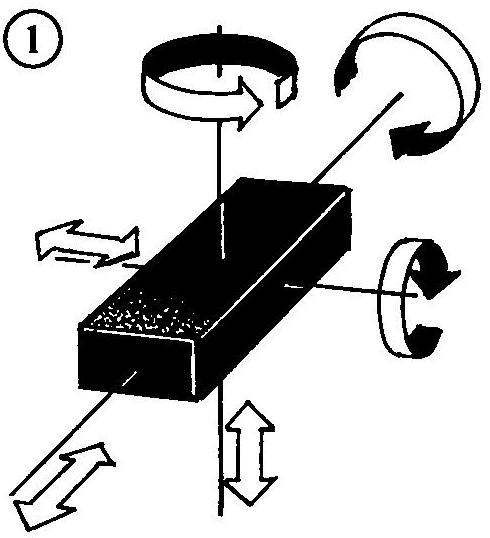

Plate, rectangular details

Such blanks secured in a vise so that the surface treatment was as close to the vise cheek. The trimmed part should be the dimensions of the grip so that during the cutting the saw handle does not hit the vise. When sawing of plates, the greatest effect can be achieved using the methods shown in figures 2A and 2B.

To processing not to scratch the item and not damage the slots of the grip, apply liners made of soft material (aluminium, copper, plastic or wood).

If a long portion of the flat blank must be bent at a right angle, the plate must hold between two steel squares (Fig. 3) long, slightly larger than the plate. The ends of the triangles should squeeze a hand grip or make them a technological hole and secure using bolt.

Processing a file of the surface of the thin plate facilitates its fixing in a Vice on a wooden block with a window with the inserted pegs (Fig.4A). For processing a file of edges of a rectangular part at an angle you can use the method of fixing shown in figure 4B.

Fig. 1. Possible variants of the shifting of parts during processing

Fig. 2. So to properly fix the plate before you saw it:

a — between the two plates, b — between the squares

Fig. 3. So it is necessary to secure the plate to bend it. Used steel angle brackets, which is a continuation of the cheeks of the grip

Fig. 4. Ways of fastening of rectangular objects for subsequent processing a file:

and — with the help of wooden blocks with pegs; — using steel squares, angled

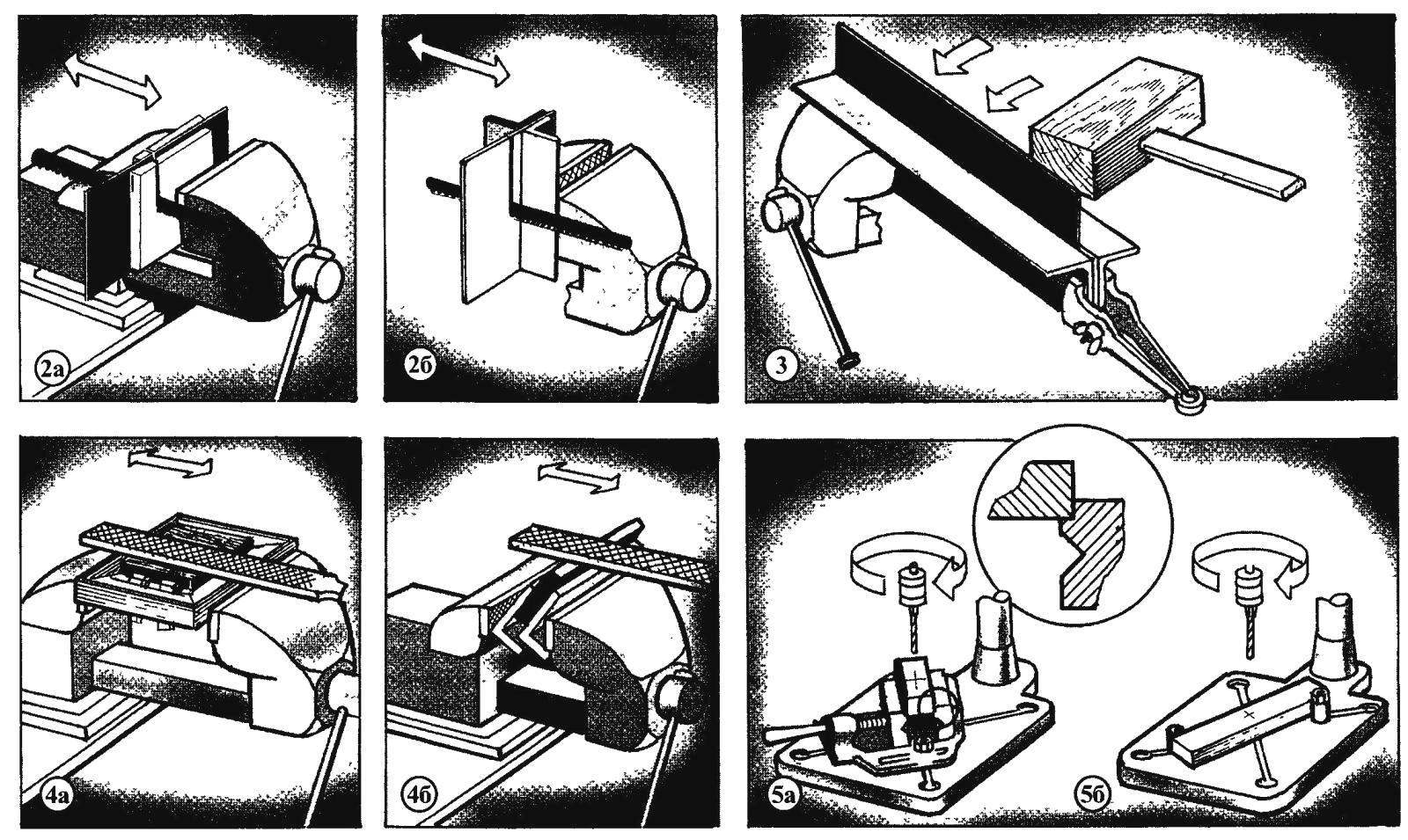

Fig. 5. Consolidation of items prior to drilling holes through them:

and — by means of model clutches, cheeks which provide perpendicular holes towards the bottom of the item — by means of support bushings (should pay attention to the axis of the hole coincides with a center hole on a drill table, as well as the fact that the support sleeve is correctly positioned)

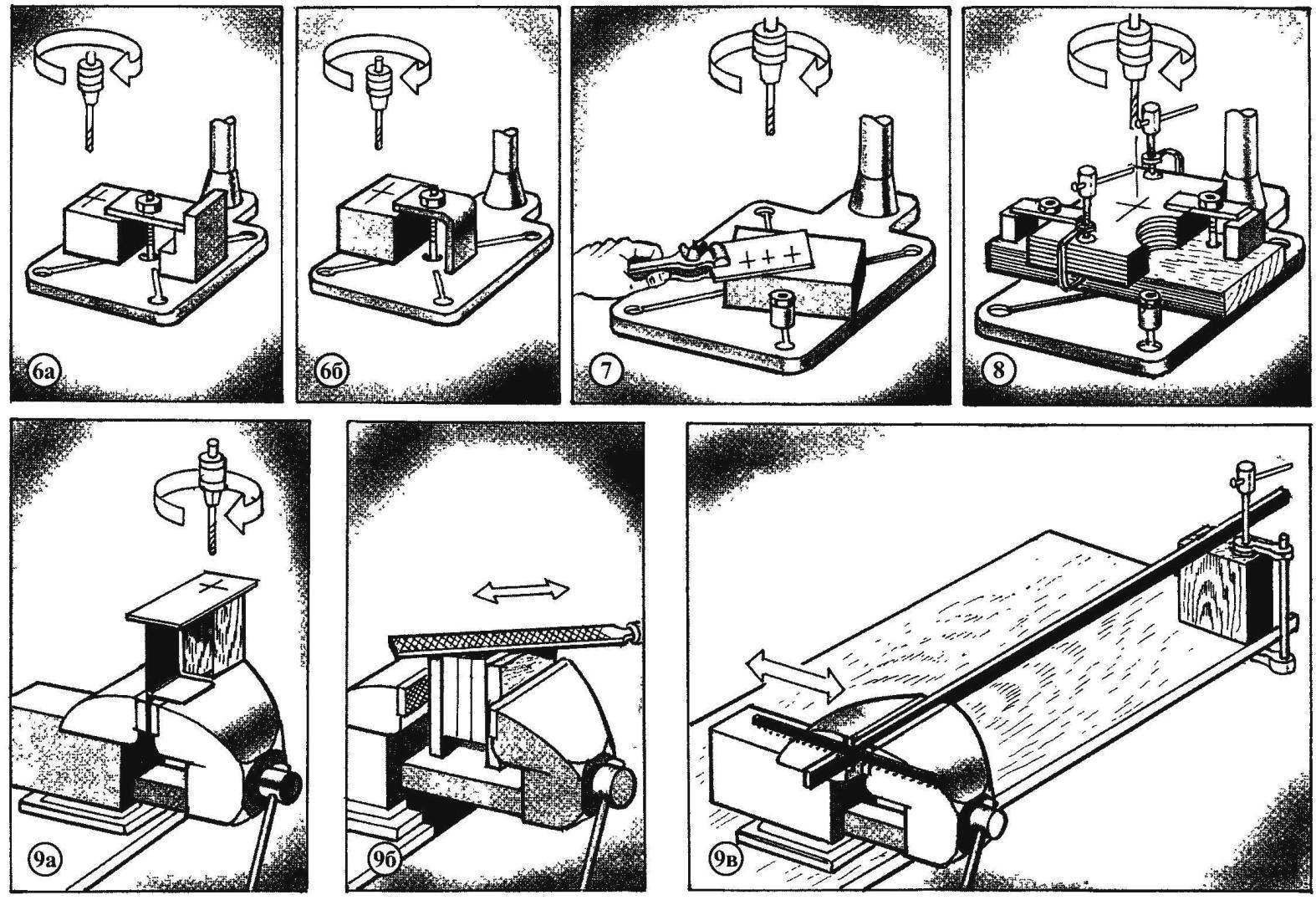

In the case where you want to drill a hole, it is necessary that the axis of the hole was perpendicular to the surface of the part in which it is done. Consolidation should provide such position of the workpiece in which it could be rotated or shifted during the operation of rotation of the drill. The drill is passing through, should not damage the fasteners and lead to unsafe rotation of the supporting liners. Examples of fastening blanks that meet these conditions are shown in figures 5A, 5B and 6A, 6b. In each case, when it is necessary to make a hole, use a hand drill, attached to the frame.

If you want to go through the hole of small diameter, the area of support for drilling may be small, it is sufficient to use a hand Vice (Fig.7). It is necessary, however, to secure the support pad to eliminate its rotation at the time of passage of the drill through the workpiece.

Often it happens that the required holes in several identical parts. In order to avoid painstaking re-operations, is sufficient to put all the parts together and tightly secured to each other, securing clamps, and then put the resulting package in the clamp and drill holes (figure 8). Simultaneous processing of multiple identical workpieces can be applied in other cases, for example, in the treatment of surfaces with a file or when sawing.

Fig. 6. Consolidation of rectangular objects when drilling holes with the clamps, consisting of multi-stage stands, holding плас1ины and screw cutting (a), or by using a square and a screw thread (b)

Fig. 7. So you can use a hand vise to hold the item where you want to drill the holes with a small diameter Fig. 8. Pinning, allowing simultaneous processing of multiple parts

Fig. 9. Additional props (a, b) or securing (b) eliminates the offset and deformation of the object during processing

Requires special attention to the fastening of parts having a complex configuration, when the design provides the necessary stability. This applies to both drill holes (Fig.9a) and other processing (Fig.9b) when you want to apply additional stoppers or liners, ensuring the rigidity of fastening of the workpiece, but excluding the deformation of the treated area. The need for additional bracing of the object is manifested primarily in the cutting of a long rectangle, a square pipe (Fig.9b).

The rental items and globular details

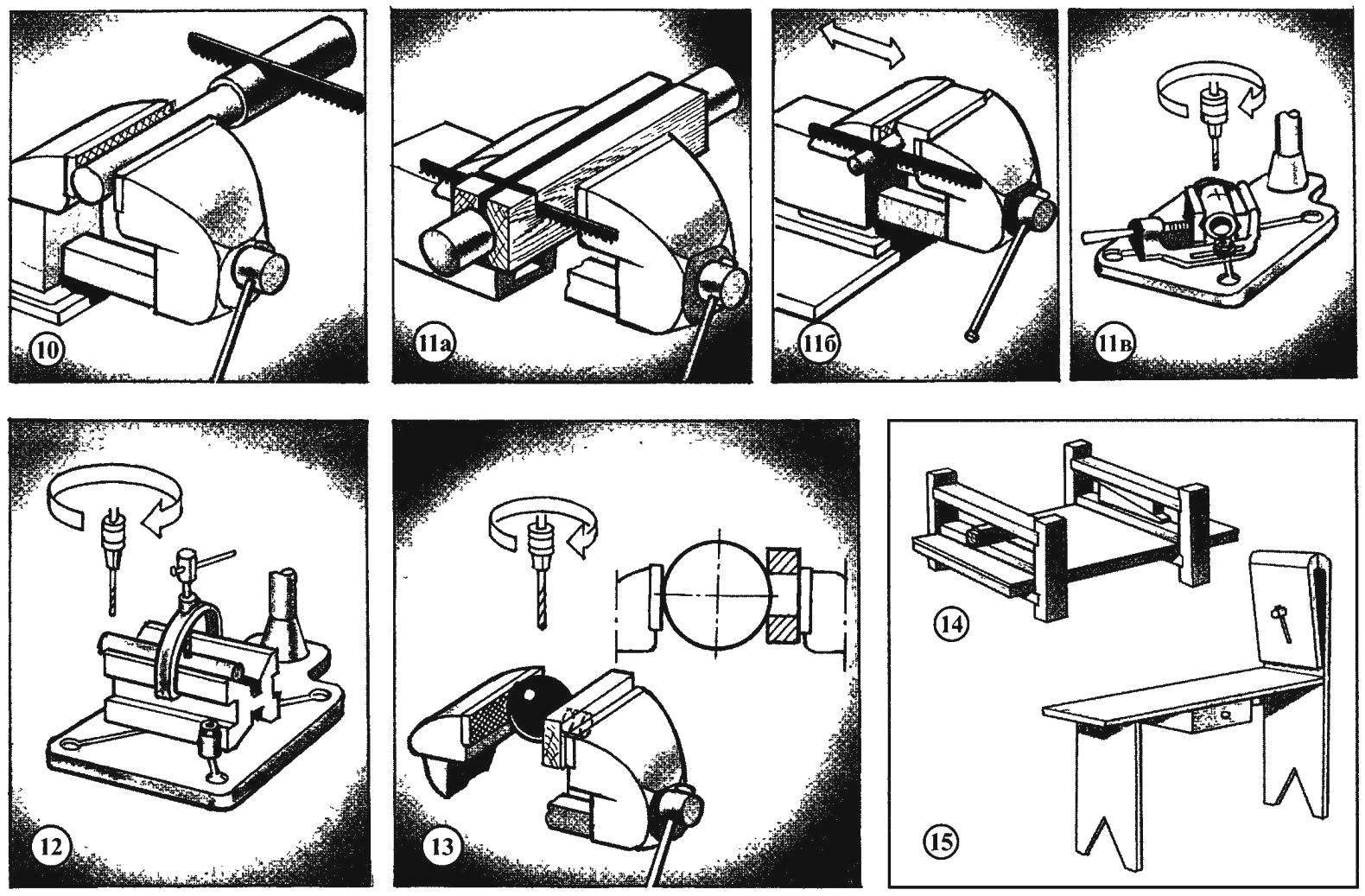

In order to cut thin-walled tubing, you can either firmly press them on the round wooden rod (Fig 10), or pinch them between the pads with indentations Doing this kind of simple training, you can safely start sawing the tube.

Tube with thicker walls, and rods of circular cross section should be secured in a vise, using prismatic ear (Fig.11a, b), or a typical vise cheeks which have a prismatic recess (Fig 11), or universal prisms. The use of such prismatic devices when securing items in the form of a roller on a drill table is also shown in figure 12.

Fig. 10. Variants of fastening of thin-walled tubes in a vise

Fig. 11. Anchoring of round bars and pipes with thick walls locksmith vise with prismatic inserts (a) and (b), and also with standard grip (b)

Fig. 12. Fixing roller with prismatic stand with clamping screw

Fig. 13. The method of fastening ball details in a vise plumbing through liner with hole

Fig. 14. The clamping device for the veneer surface furniture ЩИ10В

Fig. 15. A bench vise is very handy when performing work on the sharpening of teeths of saws

Facilitates the fixing of the balloon in the grip of a simple sack with a hole (Fig. 13):

Carpentry clamps

A lot of appliances are used when working with wood (apart from bench). For example, pressing of sheet materials facilitates a framework platform with V-clamps indispensable in the veneer (Fig.14). Veneer with a beautiful texture is rolled up on a furniture Board with an adhesive layer and covered by a smooth panel that podrazdelyaetsya wedges to the drying period. But if blunt saw or handsaw and have her teeth sharpen, a special vise with a bench, which is convenient to perform this operation (Fig. 15).

B. VLADIMIROV (on materials of foreign seal)