Machine UK-4 is still popular among hobbyists and tinkerers. Over the years of its release, home craftsmen invented many devices to improve its performance and broadening the range of operations. Many of these upgrades were reported in the “M-K”. However, nothing was said about using his motor at full capacity. But it is quite enough to handle larger workpieces than the number specified in the passport of the machine. And the need for such a feature: in this we have repeatedly seen at work in our model aircraft club. Here and was made a fixture that allowed to increase the depth of milling parts using standard cutters b to 17 mm with their width up to 260 mm instead of 60.

Machine UK-4 is still popular among hobbyists and tinkerers. Over the years of its release, home craftsmen invented many devices to improve its performance and broadening the range of operations. Many of these upgrades were reported in the “M-K”. However, nothing was said about using his motor at full capacity. But it is quite enough to handle larger workpieces than the number specified in the passport of the machine. And the need for such a feature: in this we have repeatedly seen at work in our model aircraft club. Here and was made a fixture that allowed to increase the depth of milling parts using standard cutters b to 17 mm with their width up to 260 mm instead of 60.

To this end, we extended the shaft of the machine, which is a mill, and increased the size of the working table. To replace the standard steel shaft is not (because our fixture is removable), and machined a “missing” piece and attached it with rubber tubing, fastened at the ends of the wire clamps, so it turned out coupling.

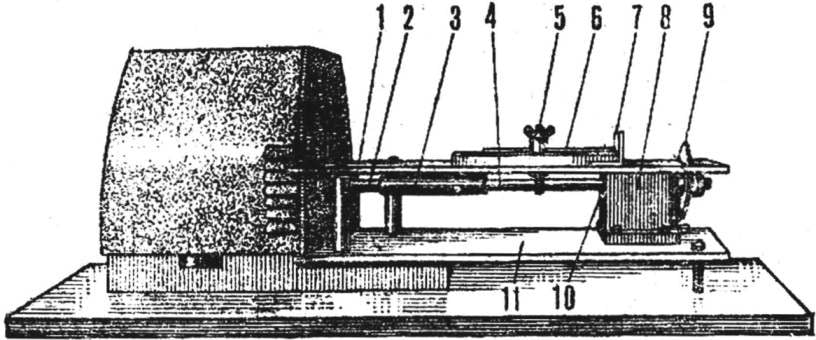

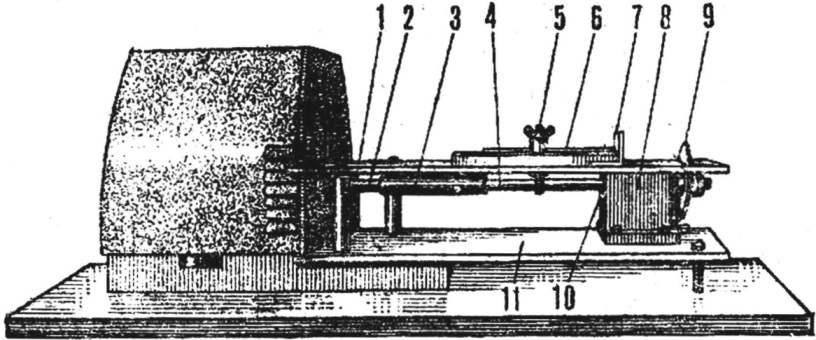

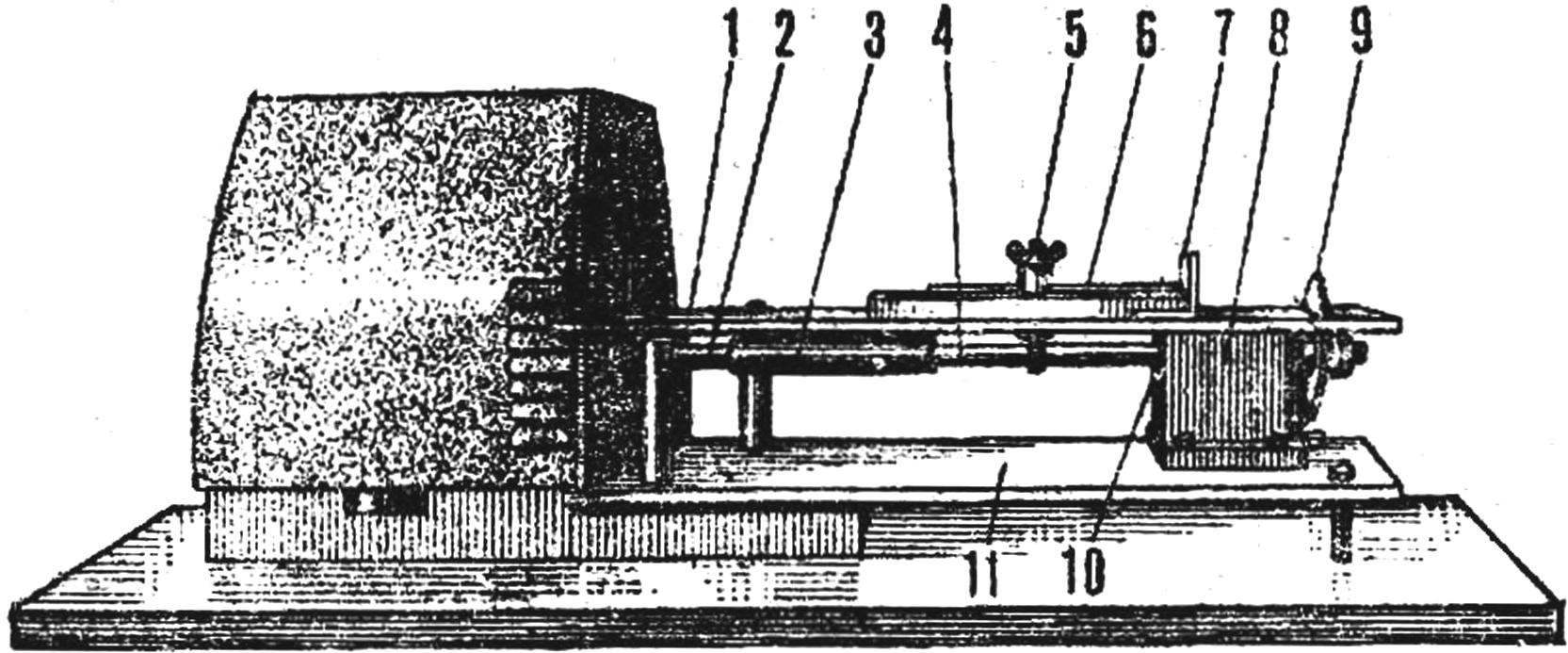

General view and main parts of the machine UK-4:

1— working table, 2 — regular shaft 3 — rubber tubing-coupling 4 — additional shaft, 5 —screw, 6 — guide, 7 — area guide, 8 — front shaft, 9 — mill, 10 — bearing cover 11 — basis.