One of the oldest and most common flooring in our country — the linoleum. Over time, this popular material have changed and improved, but in the memory of buyers are still alive old stereotypes. They often give rise to myths which we will try to debunk.

One of the oldest and most common flooring in our country — the linoleum. Over time, this popular material have changed and improved, but in the memory of buyers are still alive old stereotypes. They often give rise to myths which we will try to debunk.

Myth 1. Linoleum is not a safe materials

It should be noted that the original linoleum was a completely natural material made from flax, oil and resin. Modern flooring materials are mainly produced from synthetic polymer — polyvinyl chloride (PVC). In Europe and the USA they are called not linoleum and PVC coatings. In Russia, however, prefer to use the old name.

PVC has today become the most widespread. It is a raw material for products used in different areas, including those where safety becomes the main criterion: medicine, food industry, baby products. The degree of environmental friendliness of the final product depends on several factors, including used new production technology and harmlessness used in the manufacture of raw materials. In the end, every product must meet a number of requirements. Confirm its safety for human health is called a health certificate. For many commodities it is a binding document. While the system of voluntary certification, in which the product itself and its production process are also subjected to thorough examination. For example, the materials of the flooring company Tarkett was similar test, the results of which linoleum has received the international eco-label “Leaf of life”. The company’s products was rated the highest level of environmental safety for human health.

PVC has today become the most widespread. It is a raw material for products used in different areas, including those where safety becomes the main criterion: medicine, food industry, baby products. The degree of environmental friendliness of the final product depends on several factors, including used new production technology and harmlessness used in the manufacture of raw materials. In the end, every product must meet a number of requirements. Confirm its safety for human health is called a health certificate. For many commodities it is a binding document. While the system of voluntary certification, in which the product itself and its production process are also subjected to thorough examination. For example, the materials of the flooring company Tarkett was similar test, the results of which linoleum has received the international eco-label “Leaf of life”. The company’s products was rated the highest level of environmental safety for human health.

Myth 2. Linoleum fell out of fashion

Today there are a huge number of new types of flooring. However, even the fierce competition does not interfere with the linoleum remain the absolute leader of consumer preferences. So, according to research Agency DISCOVERY Research Group, in 2008, he was ranked first in terms of production in our country. Assessing the Russian market of floor coverings, experts note that the share of linoleum 40% of total sales. In this case in different price categories, from the most economical (100 — 150 $ /m2) to the prestigious (up to 1500 $ /m2).

Today there are a huge number of new types of flooring. However, even the fierce competition does not interfere with the linoleum remain the absolute leader of consumer preferences. So, according to research Agency DISCOVERY Research Group, in 2008, he was ranked first in terms of production in our country. Assessing the Russian market of floor coverings, experts note that the share of linoleum 40% of total sales. In this case in different price categories, from the most economical (100 — 150 $ /m2) to the prestigious (up to 1500 $ /m2).

Depending on the production technology of the material is divided into heterogeneous and homogeneous. Heterogeneous coatings are multi-layer sheet with thickness of 6 mm. Normally, it consists of an upper working layer (transparent PVC), decorative, internal reference (foamed PVC and fiberglass) and rear (base). In such a material structure drawing protected by a transparent wear layer of PVC. The thickness of the linoleum, stacked in living rooms and bedrooms may be about 0.15 mm. And for the corridor, hallway and kitchen is recommended to choose more durable options with active layer thickness of 0.25 mm. There are also special commercial coatings, in which the figure is 1 mm. to increase the durability and make the care of linoleum is easier, many manufacturers additionally treated with a special lacquer finish: polyurethane or polyacrylic. This ensures service life up to 15 — 20 years.

Homogeneous linoleum — a single layer of PVC material with thickness up to 3 mm. coating Structure and creates a picture, so this linoleum unique in its kind can be updated, removing the top layer, as in sanding parquet flooring. However, this technology allows to cover with only simple kinds of colors: solid or granulated (like marble).

Linoleum and, and other species may have different characteristics, so the choice is first and foremost to pay attention to this class of durability.

Myth 3. Linoleum — “cold” cover

To characterize the flooring specialists use an indicator such as the absorption. It demonstrates how quickly heat absorbed sole of the foot floor construction. Consequently, his value depends on how warm the material seems to touch people. According to the norms of this index for household flooring must not exceed 12 W/m2*K. Accordingly, materials having a large absorption, for example, ceramic tiles, quickly absorb the heat and it feels cooler. The linoleum value of this index depends on the density of the coating, it also determines the presence and thickness of the base. The last is the back layer of the material and usually made of polyester or foam PVC.

To characterize the flooring specialists use an indicator such as the absorption. It demonstrates how quickly heat absorbed sole of the foot floor construction. Consequently, his value depends on how warm the material seems to touch people. According to the norms of this index for household flooring must not exceed 12 W/m2*K. Accordingly, materials having a large absorption, for example, ceramic tiles, quickly absorb the heat and it feels cooler. The linoleum value of this index depends on the density of the coating, it also determines the presence and thickness of the base. The last is the back layer of the material and usually made of polyester or foam PVC.

If to compare two types of heterogeneous linoleum of the same thickness, it is better at trapping heat in the textile material basis. Previously, it produced of natural felt, which was exposed to statybiniu was afraid of the humidity. Devoid of these shortcomings, the basis of polyester, which is sometimes called artificial felt, because it is a non-woven, similar in structure material. Polyester does not rot, not afraid of changes in temperature. The rate of heat absorption of some linoleum on that basis 9 — 10 W/m2*K.

It should be noted that some of the coating to the back layer of PVC on its thermal insulation properties are not inferior to materials in textiles. The characteristics of linoleum on the basis of PVC depends on the thickness of the coating and density of the foam.

Produced material and laminated with PVC and polyester, which combines the advantages of these two materials.

Myth 4. Linoleum is easily torn and stretched

A “skeleton” of the current heterogeneous cover is fiberglass. Thanks to his presence and strength of the multilayer structure of modern linoleum significantly higher than the previously common materials. Additionally, the fiberglass preserves the linear dimensions of the canvas. This means that the coating will not stretch and will not shrivel with time, treacherously crawling out of the woodwork. In addition, modern linoleum is made on the basis of PVC foam, whose components are more strongly related to each other, which gives additional strength to the material.

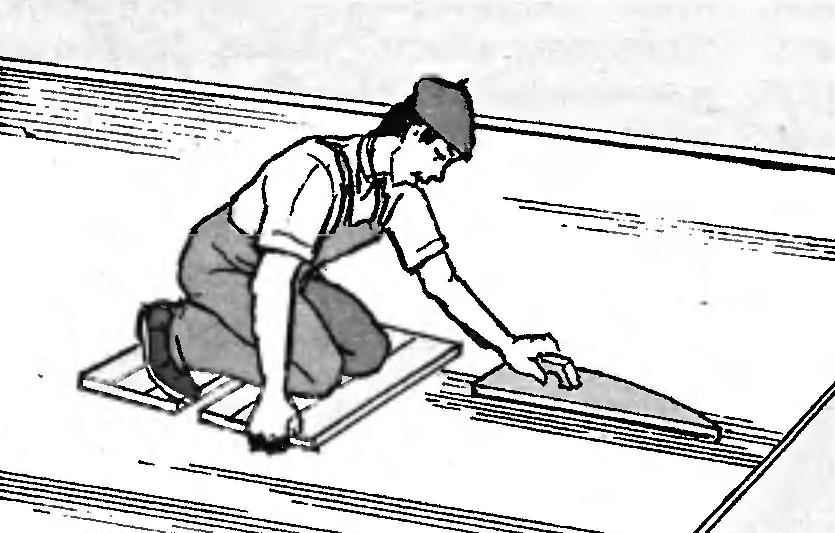

However, when even the flooring surfaces must be sound in mind about the basic rules of styling. Often linoleum lay on the old floors, such as parquet. If his plates were cracked and chipped, over time, these defects can be stamped on the linoleum. To prevent such problems it is necessary to thoroughly clean and smooth the surface of the base.

Myth 5. When laying linoleum visible seams

20 years ago a similar problem occurred very often. In the market of linoleum were presented in limited quantities and mainly with standard roll widths 1.5 — 2 meters. Today, the buyer initially has the opportunity to choose the right size cover. For example, among household Tarkett collections are the products of a width of from 1.5 to 4 meters. In addition, the possible joining of webs of linoleum, which is recommended to use a modern cold welding technology. This is performed using a special glue that not only binds two banners, and, dissolving, actually melts and welds the edges of the linoleum. This ensures the highest degree of reliability of connections, and the seam is almost invisible. This method is appropriate for bezosnovnyj linoleum, and ground.

20 years ago a similar problem occurred very often. In the market of linoleum were presented in limited quantities and mainly with standard roll widths 1.5 — 2 meters. Today, the buyer initially has the opportunity to choose the right size cover. For example, among household Tarkett collections are the products of a width of from 1.5 to 4 meters. In addition, the possible joining of webs of linoleum, which is recommended to use a modern cold welding technology. This is performed using a special glue that not only binds two banners, and, dissolving, actually melts and welds the edges of the linoleum. This ensures the highest degree of reliability of connections, and the seam is almost invisible. This method is appropriate for bezosnovnyj linoleum, and ground.

Linoleum is laid on a flat base, couplers from a polymer solution, wood fiber boards or drywall sheets. Before laying the thin polymer coating is necessary to complete all construction, plumbing, electrical work.

In the main working operations includes cleaning and leveling the surface, priming it, flooring wood fiberboard on mastic, assessment and ageing of the cut linoleum, linoleum partial prirezka of the contour drawing on the base of mastic and adhering the carpet, rolling on the linoleum, cutting a throat and gluing in joints, installation of plinths.

The device of cement base includes the following processes: a device of the subfloor, laying jointing, filling the space between the rails and joints after removal, the grout surface.

After the training grounds to meet his primer for better adhesion of the layer: adhered to the mastic base primed with a solution of bitumen in gasoline in the ratio 1:3; if you use glue “Bustilat” primer perform 15% aqueous solution of glue.

For one-two days before the stickers linoleum is rolled out and kept in a warm room, to avoid waviness in the hair and straighten the folds remaining after storage in rolls. Rolled cloth prirezajut on the spot, mark its position on the floor and re-rolled into a roll to the middle. On a net basis is applied with a notched trowel a thin layer of mastic (1 mm) and gradually unroll the folded part of the cloth, Primera linoleum on top of cloth from the middle to the side edges so that under it had no air. The following panel stack overlap (overlap edges) 5 — 10 mm. linoleum Edges connecting to it should not stick, do this after connecting, and at the edges, and tie additional mastic is applied. After two or three days after removing the residual linear deformation and evaporation through the joints of the solvent, the two layers of linoleum prirezajut on the steel ruler. The sutures applied Reiki and inventory tightening weight. Contaminated with mastic places on the linoleum wiped with a rag, removing from the surface excess of the composition. To walk on the floor only a day later. After gluing of joints of linoleum installed wooden wainscoting, nailing up.

When the coating of a roll of carpet materials are used two method of laying: gluing and laying on the ground with the pin around the perimeter of the room.

When cutting linoleum you should consider the location of the paintings in the room: the paintings and monochrome marbled linoleum should be laid in the direction of the light beam. Such direction hides the seams, the floor becomes a monolith.

In the corridors of the canvas of a single color linoleum should be located along and marbled — wide. Canvas linoleum print lay in the longitudinal direction, picking up the picture. You need to choose the direction of the inclination of the pile: for the panels it should be equally directed and preferably from the window. Carpets cut into cloths and laid with the overlap of the edges. In the unfolded state of the cloth can withstand up to complete disappearance of the waviness for two days.

Carpet materials are bonded with dispersion adhesives (based on synthetic resins and rubbers). Before the flooring prepare base: clear cracks and damage to the screed, remove dust, dried to a moisture content of not more than 5%.

Sticker williamsis the carpet roll to roll to the middle. On the base is applied with a spatula a layer of adhesive KN-2, KN-3 with a thickness of 0,6 — 0,7 mm, leaving a free strip of width 100 — 150 mm along the edges of the carpet for subsequent connecting of joints. When using dispersion adhesives carpet glued to the base immediately, and the application of the adhesives based on synthetic resins and rubbers — in 15 — 20 minutes after applying the adhesive to the base. The carpet is first pressed against the base along the axial line along its middle, and then smooth from the middle to the edges: carpets prirezajut joints are glued, not earlier than three days after the stickers went to the shrinkage. Prirezku edges of the carpet are produced similarly prirezke edges of the linoleum.

Sticker williamsis the carpet roll to roll to the middle. On the base is applied with a spatula a layer of adhesive KN-2, KN-3 with a thickness of 0,6 — 0,7 mm, leaving a free strip of width 100 — 150 mm along the edges of the carpet for subsequent connecting of joints. When using dispersion adhesives carpet glued to the base immediately, and the application of the adhesives based on synthetic resins and rubbers — in 15 — 20 minutes after applying the adhesive to the base. The carpet is first pressed against the base along the axial line along its middle, and then smooth from the middle to the edges: carpets prirezajut joints are glued, not earlier than three days after the stickers went to the shrinkage. Prirezku edges of the carpet are produced similarly prirezke edges of the linoleum.

Edge glued linoleum as well as carpeting. Speaking from the intersection of glue and remove with a cloth. Maintenance of carpet is possible within three days after sticker.

The edges of linoleum along the walls of the closed wood or PVC skirting. PVC skirting warm over hot water, from which it loses stiffness quickly wipe with a dry cloth and glued to the quick-drying, coumarone-rubber mastic KH-2 KH-3. The surface of the wall in the places of gluing skirting boards pre-primed with mastic. Uneven surface shpatljujut the same mastic (KN-2) add sifted cement, leaving for a few hours. Then smear the plinth and the Foundation under it with a thin layer of fresh putty, allowed to stand for 10 to 15 minutes for volatilization of a solvent and tightly pressed against the skirting Board to the wall, wiping it with a rag.

When laying the seams on the linoleum with drawing it is recommended to Orient parallel to the direction of light, in this case they will be virtually invisible.

Modern linoleum is more functional and attractive. And because of that fact old myths associated with its use, are gradually disappearing. And in their place come the facts that look more convincing than stereotypes and speculation.

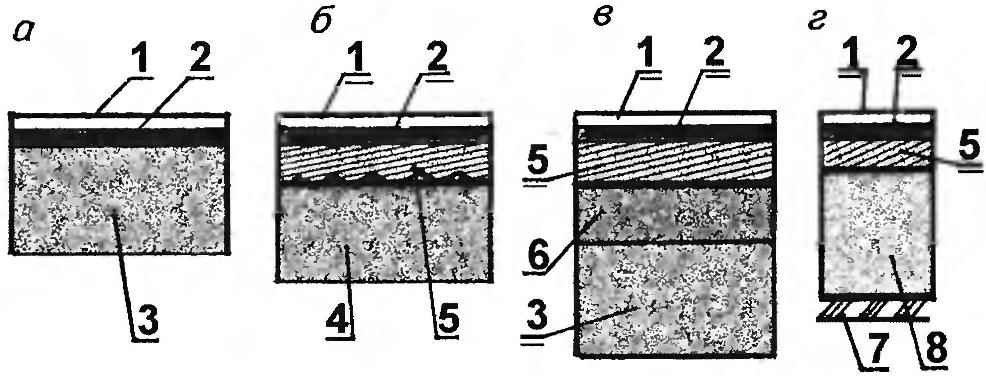

Onoznacenie:

Laying linoleum mastic

(a—directly on a level concrete slab;

b—on uneven overlapping of the screed;

in—screed heat-insulating layer;

Mr. clay):

1 —linoleum;

2—adhesive layer;

3—slab with a smooth surface;

4—a plate with a rough surface;

5—tie;

6—heat or zvukoizoliruyuschie;

7—soil basis;

8—concrete sub-base.