The most common version of a tool box for both professionals and hobbyists is usually just a wooden box with a carrying handle. Accordingly, its contents typically lie, as they say, in a heap: tools, fasteners, devices — all mixed together. Attempts to make compartments or insert additional boxes don’t help: it’s still inconvenient to use.

Imported boxes with built-in sections have appeared on the market, allowing for internal organization, but their price is often higher than any power tool.

Meanwhile, our reader from Ryazan B. Potapov found a solution without foreign purchases by designing a simple and original multi-tier box that is spacious and very convenient to use. Its design is quite universal and will be useful not only, say, for carpentry needs, but also for any woodworking, metalworking, and other tool sets and auxiliary small items. And for a home craftsman, this practically solves the workshop problem: all his arsenal will be stored in one place.

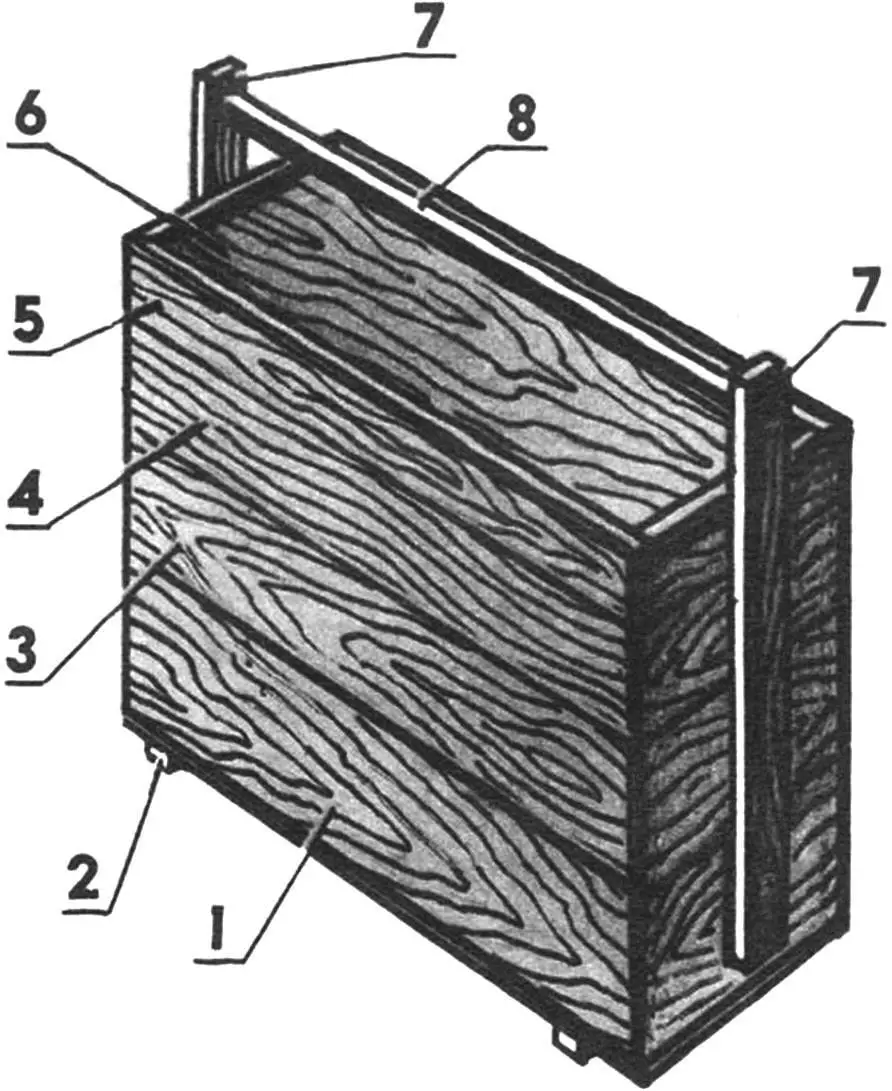

1 — base box; 2 — support leg; 3,4 — middle boxes; 5 — top box, sectional; 6 — sliding lid; 7 — posts; 8 — tubular handle.

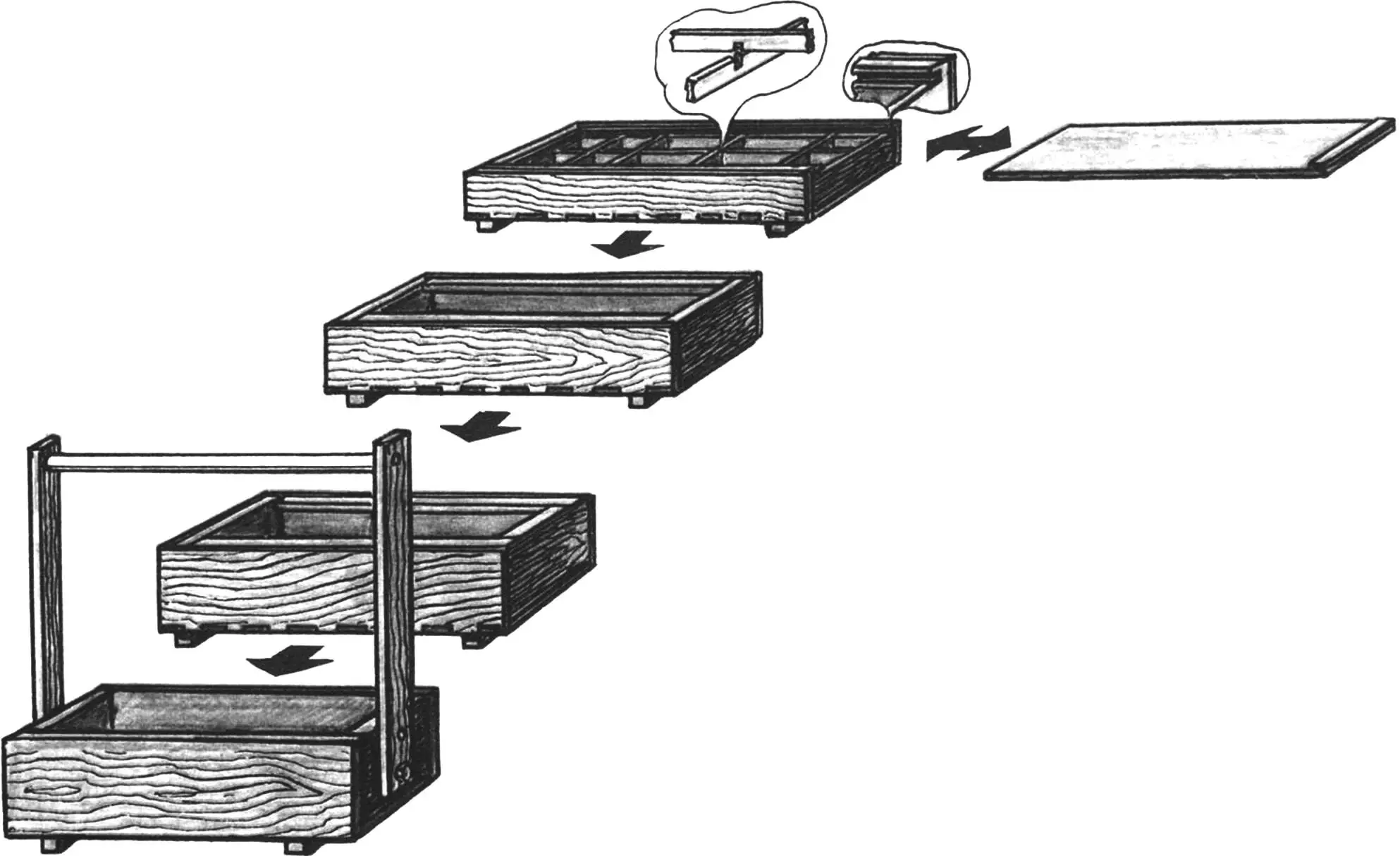

I have been using my tool box for more than a year now and am very satisfied with it. As practice has shown, it is free from many shortcomings of existing designs and, on the contrary, has advantages. And first of all, it is multi-tier, with each box that makes up this “skyscraper” being autonomous, freely removable and usable independently. In addition, the boxes can be of different sizes depending on their purpose.

The foundation of the entire structure consists of the base box and two posts attached to its end walls, between which the other boxes are stacked one on top of the other. On the bottom of each of them there are fixing legs made of wooden bars that prevent lateral and end shifts of the boxes when assembled. A tubular handle for carrying is attached to the top of the posts.

The base box, since it is the main one and intended for large and heavy tools, can be made from thin boards or plywood 8 mm thick (side walls) and 12 mm (end walls); the bottom — from 4 mm thick plywood. The posts are fastened from below with bolts and nuts, and above them — with screws. The walls and bottom are connected to each other with small nails, with the joints pre-coated with wood glue or PVA.

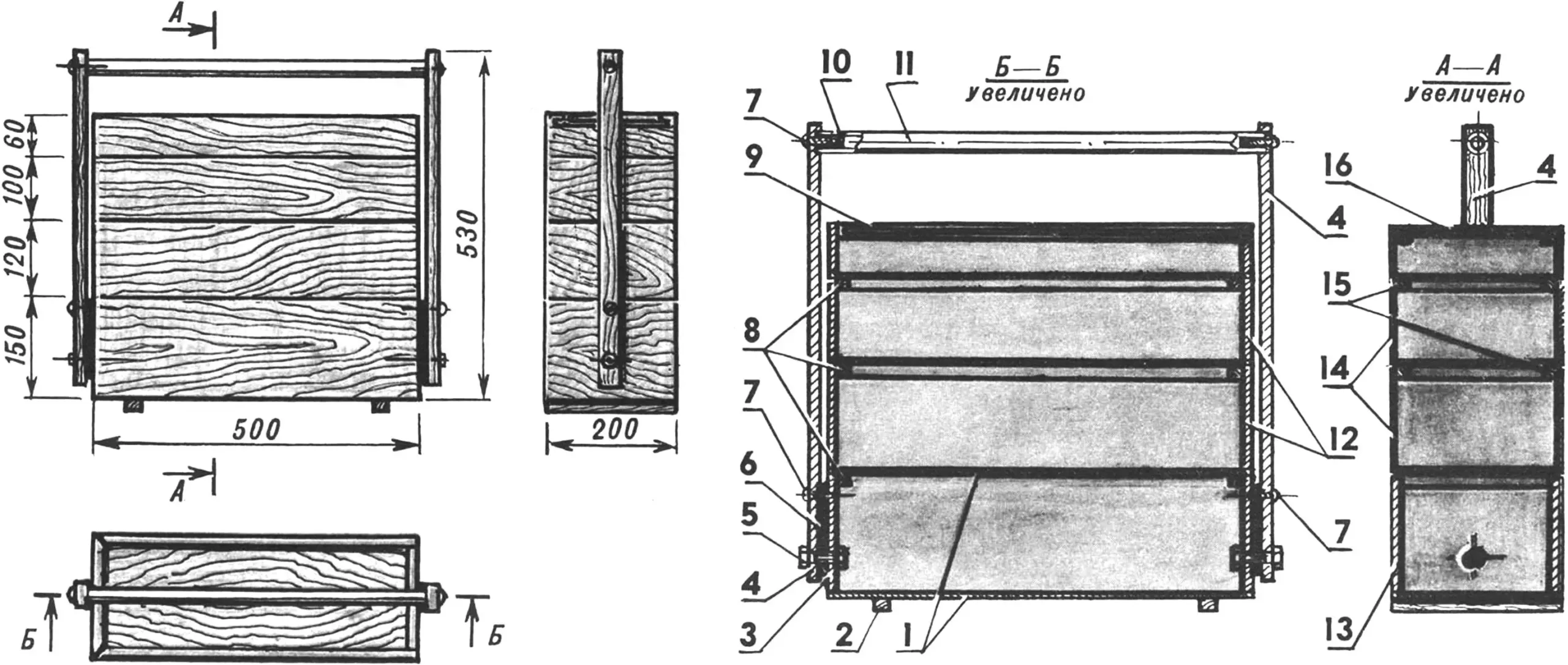

1 — bottom (plywood s4); 2 — support leg (bar 12×12, L200); 3 — lower box wall, end (plywood s8); 4 — post (bar 40×20, L500); 5 — mounting bolt M10; 6 — spacer (plywood s4); 7 — screws 3×40; 8 — fixing legs (bar 12×12); 9 — guide runner (bar 12х12 with longitudinal groove); 10 — wooden boss; 11 — handle (tube Ø16); 12 — middle boxes walls, end (plywood s12); 13 — lower box walls, side (plywood s8); 14 — middle boxes walls, side (plywood s4); 15 — reinforcement ribs (bar 12×12); 16 — sliding lid (plywood s4).

The other boxes are plywood (but the side walls are 4 mm thick), they are assembled using the same technology, or with mortise and tenon joints. Since their side walls are thinner, their upper edges can be reinforced from the inside with thin bars.

The top box design is somewhat different. First of all, it has a sliding lid, for which the side reinforcement bars are equipped with longitudinal grooves and serve as guides. And the internal space of the box is divided by partitions into cells, in which it is convenient to keep fasteners and small auxiliary parts.

The finished tool box should be impregnated several times with hot linseed oil to protect it from moisture, and if desired — painted with enamel of a non-marking color.

The other boxes are plywood (but the side walls are 4 mm thick), they are assembled using the same technology, or with mortise and tenon joints. Since their side walls are thinner, their upper edges can be reinforced from the inside with thin bars.

The top box design is somewhat different. First of all, it has a sliding lid, for which the side reinforcement bars are equipped with longitudinal grooves and serve as guides. And the internal space of the box is divided by partitions into cells, in which it is convenient to keep fasteners and small auxiliary parts.

The finished tool box should be impregnated several times with hot linseed oil to protect it from moisture, and if desired — painted with enamel of a non-marking color.

“Modelist-Konstruktor” No. 10’99, B. POTAPOV