The tinkerers are offered interesting options for upgrading ordinary electric drill, which introduced its readers the magazine “Practic” (GDR). Due to the small additions, it becomes a blade or a jig saw.

The tinkerers are offered interesting options for upgrading ordinary electric drill, which introduced its readers the magazine “Practic” (GDR). Due to the small additions, it becomes a blade or a jig saw.

These combined tools are the same: crank mechanism with the connecting rod generates forward movement of the working body of the tool.

Such devices facilitate the work with sheet material (plywood, plexiglass, etc.) at home, save time and effort, and the result is much better than with a manual tool.

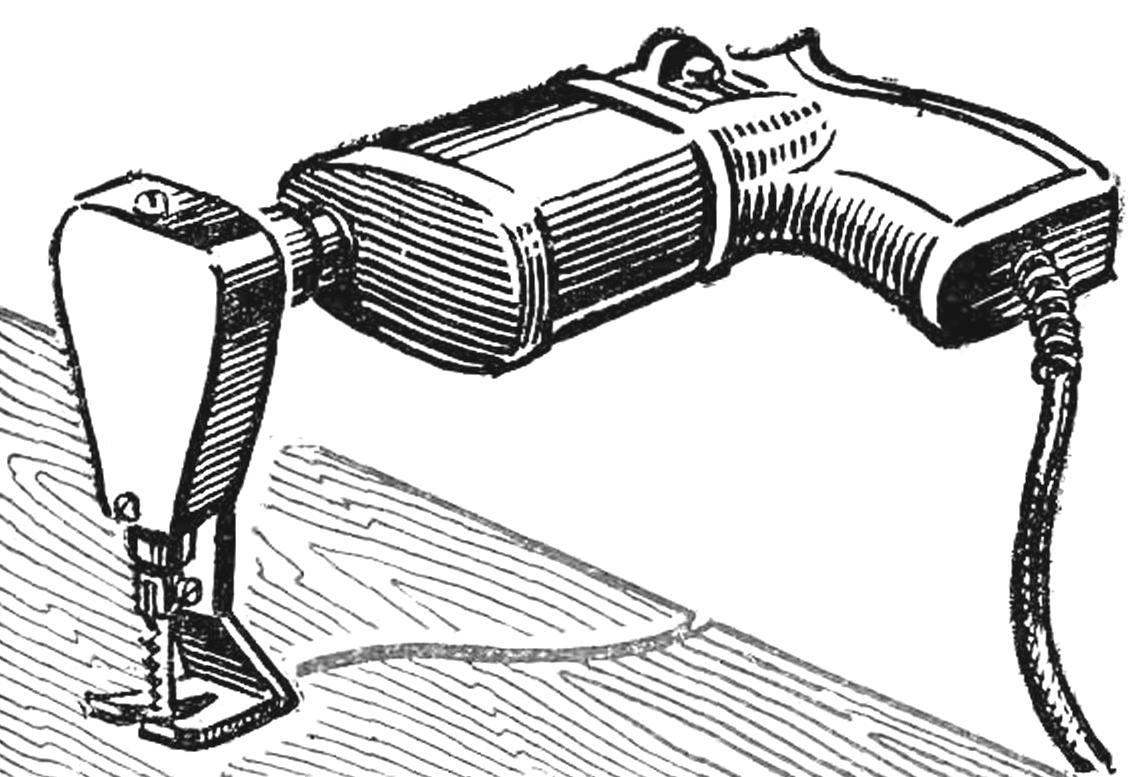

SAW

The main detail for the Assembly of this saw is the mounting plate, which is attached to fixture parts. Sleeve soldered to it a brass or copper. The inner diameter of the sleeve depends on the size of the front housing of drill to which the grommet is attached with a screw.

Fig. 1. The drill saw Assembly.

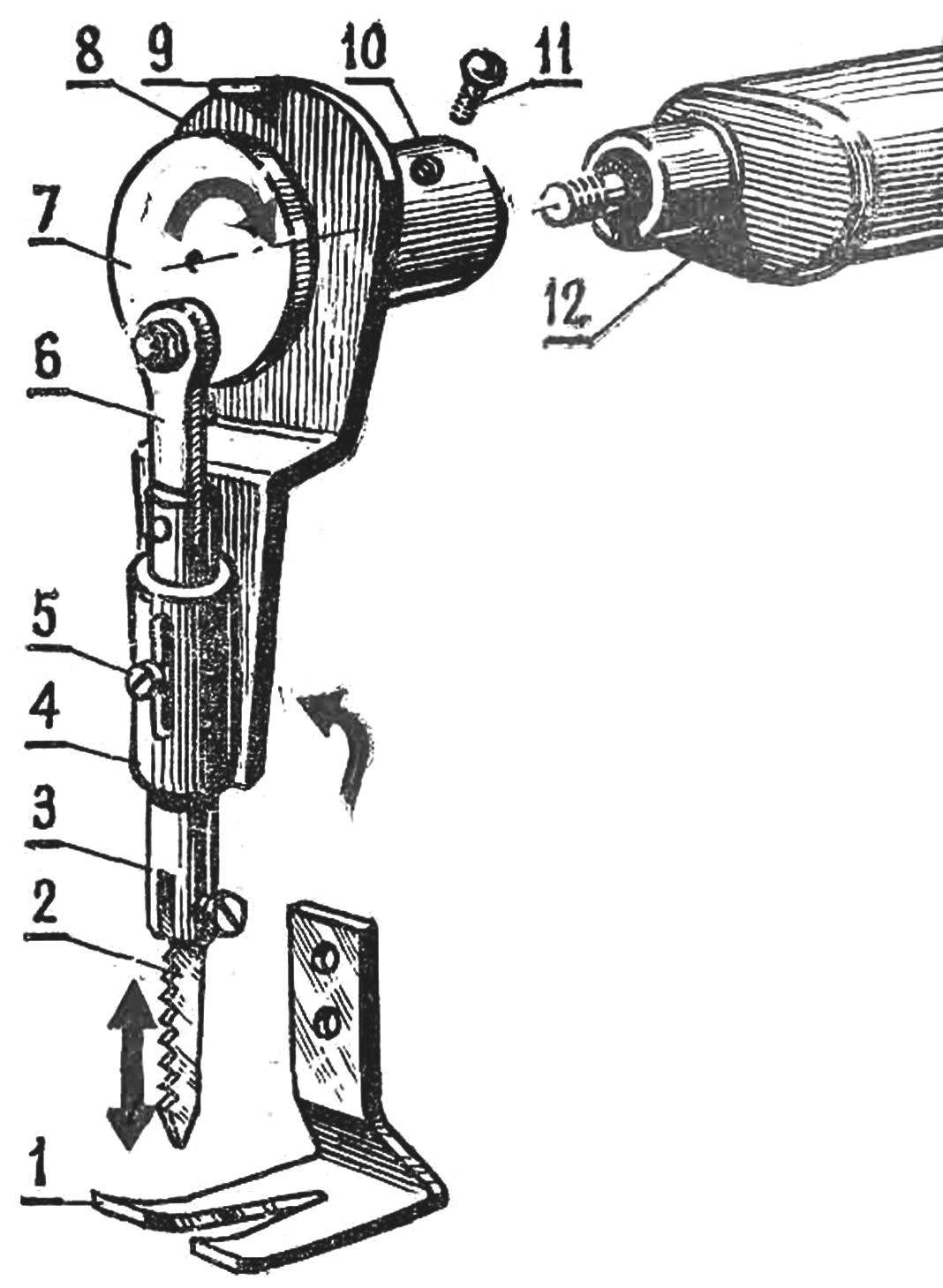

Fig. 2. Details drills-saws:

1 — support foot, 2 — blade, 3 — cross, 4 — guide bushing, 5 — screw, 6 — rod, 7 — crank, 8 — panel, 9 — area fastening of the casing, 10 — bushing, 11 — screw, 12 — drill.

On the other hand to the panel krepjat other parts of the mechanism: the guide sleeve, supporting the foot, the area of fastening of a casing, casing. The free end of the crank shaft ends with a taper corresponding to the landing nest in drills, and held there by a tight fit. Crank radius connecting rod and axle is equal to 6 mm. For enclosure of moving parts worn cover that attaches to the area with screw hole, riveted to the top of the panel.

The interaction of the parts of the mechanism it is clear from the General pattern.

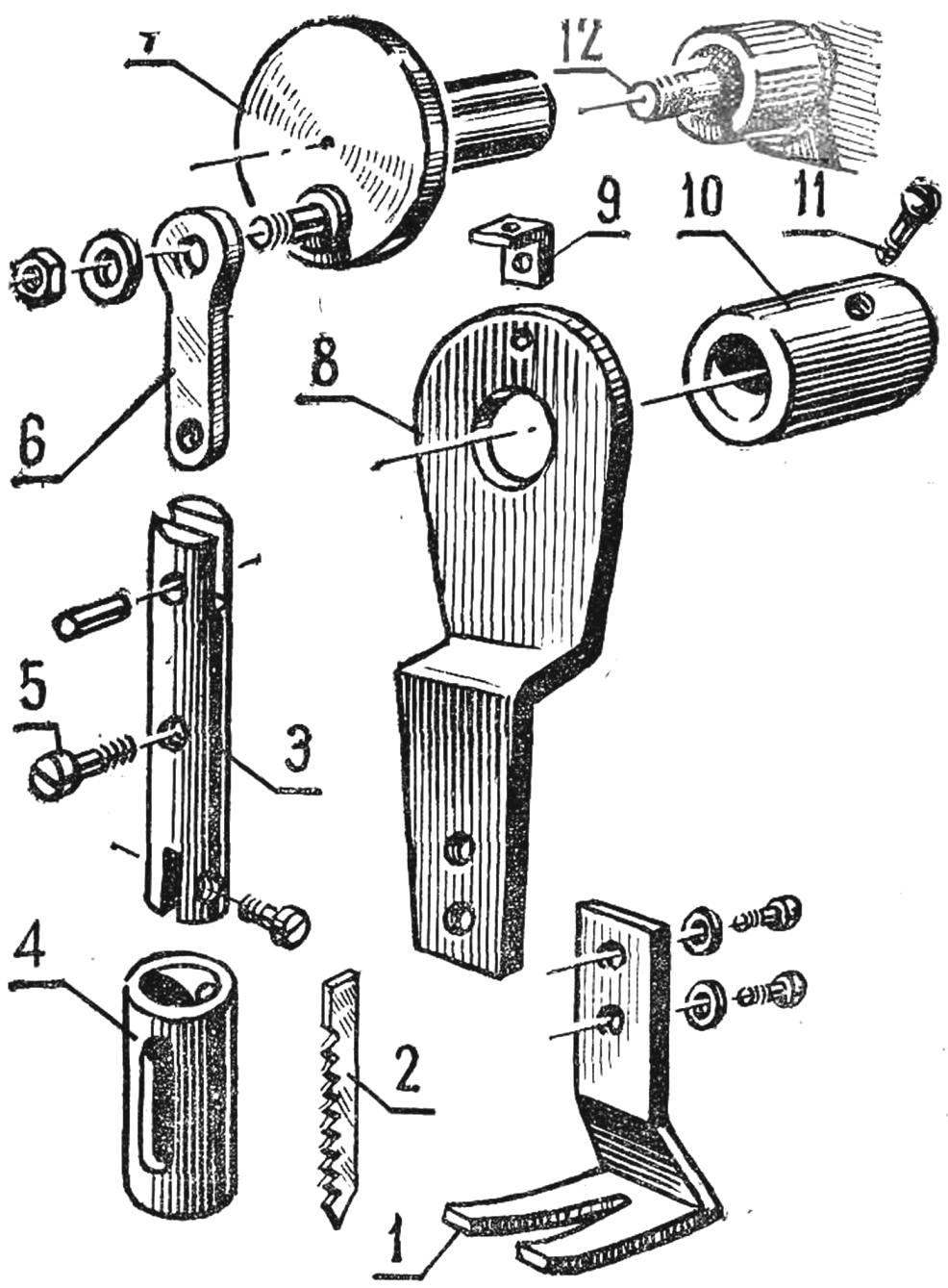

JIGSAW

The same method can be used to adapt the drill to drive the jig saw. The only difference is that the torque transfer from the drill to the pulley of the crank is made of rubber or leather pasik.

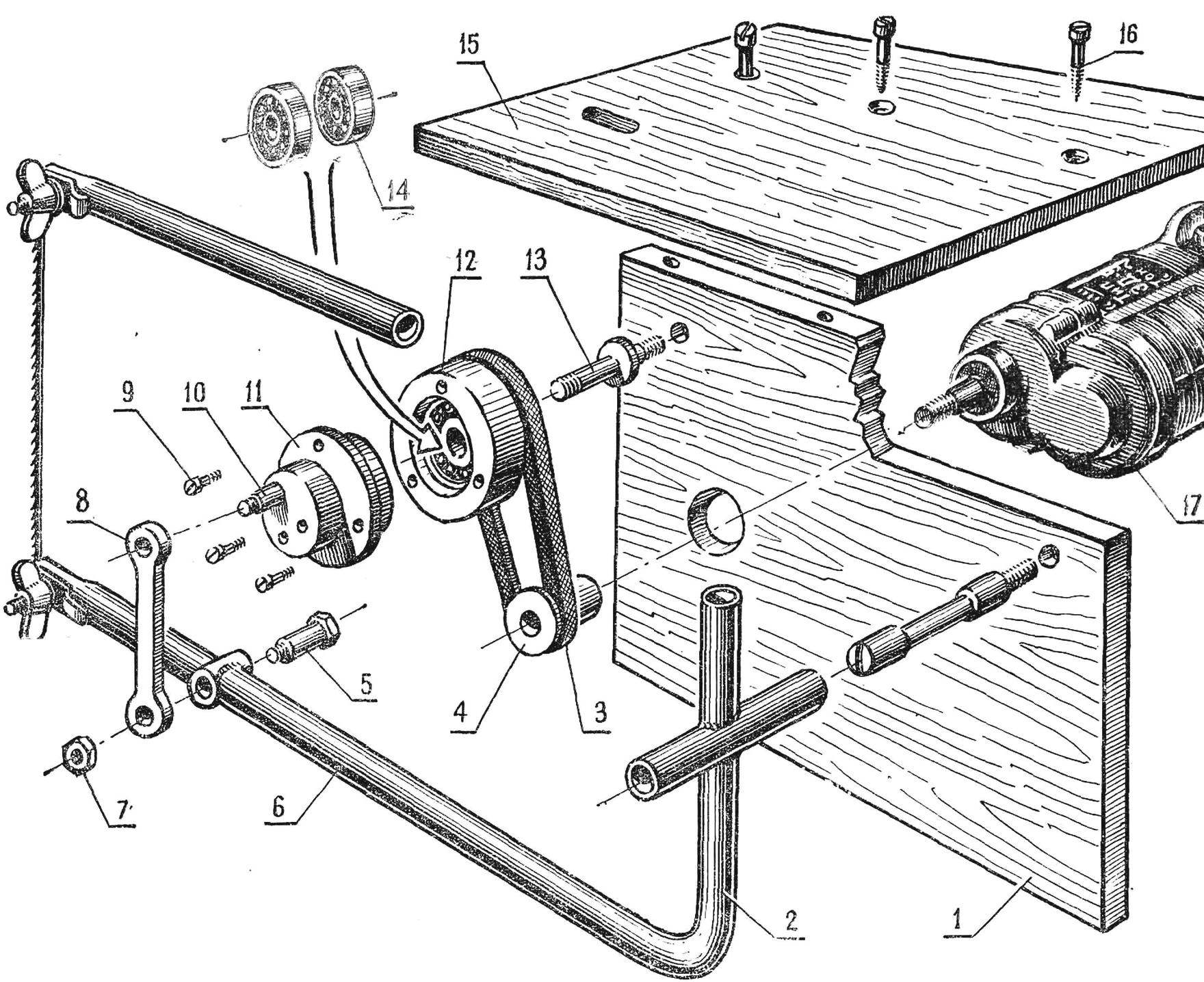

Fig. 3. Details of drill-jig saw:

1 panel; 2 — axis; 3 — pasik; 4 — pulley; 5 — a bolt; 6 — jig saw; 7 — nut; 8 — rod; 9 — screw; 10 — pin; 11 — faceplate; 12 — pulley; 13 — axis; 14 — bearings; 15 — Desk; 16 — screw; 17 — electric.

Frame construction is a panel, on it is mounted the hub axle of the jigsaw, the axle bearings of the crank pulley, Desk, etc. drive pulley attached to a thread to the mandrel, inserted in the drill.

To change the working stroke of the saw blade to move the axle rod in the threaded holes of the faceplate, remote at different distances from the axis of rotation.