In the conditions of the automated production of metal-cutting tools are especially high requirements of reliability and durability, especially when cutting hard materials and alloys.

In the conditions of the automated production of metal-cutting tools are especially high requirements of reliability and durability, especially when cutting hard materials and alloys.

Given these requirements, the participants HIM Ternopil combine plant has developed a so-called rotary cutter. Unlike normal, the holders of which is fixed cutting plate, a round carbide head, able to rotate (hence the name rotary).

The possibility of rotation of the cutter provides undeniable advantages to this tool, as the cutting edge is not working any one side, and consistently the entire perimeter, allowing less wear.

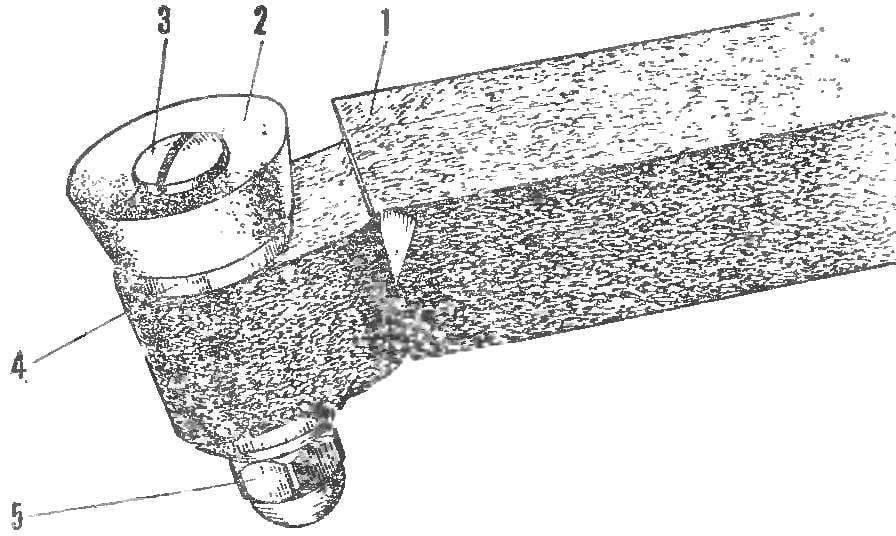

Rotary cutter:

1 — holder, 2 — rotary cutting head, 3 — axis screw 4 — washer 5 — nut.

Turning carbon, alloyed, constructional and heat-resistant steels such tool is available with high load cutting speed in the range of 300-400 mm/min, feed 6.5 to 1.0 mm/Rev and depth of cut 0,2—1,0 mm. Rotary turning tools in comparison with the usual have a higher resistance, while providing processing of high grade surface finish.