No one is surprised that for drilling different holes require different tools. The bit set can not do, does not matter. The trouble is that the tool change takes a lot of precious minutes. How to avoid this! In various companies are innovators in different ways solve this problem. There was, for example, drill bits with a stepped diameter, one such tool allows you to drill small and large holes. And where this range should be really very great work on the turret with permanently fixed at their range of drills.

No one is surprised that for drilling different holes require different tools. The bit set can not do, does not matter. The trouble is that the tool change takes a lot of precious minutes. How to avoid this! In various companies are innovators in different ways solve this problem. There was, for example, drill bits with a stepped diameter, one such tool allows you to drill small and large holes. And where this range should be really very great work on the turret with permanently fixed at their range of drills.

A different path went to the innovator Yury Sidorov. Punching large holes in thin sheet materials, he developed a cutter, which can be called “rubber”… a Tool, of course, made of metal, but can be “stretched” in a wide range.

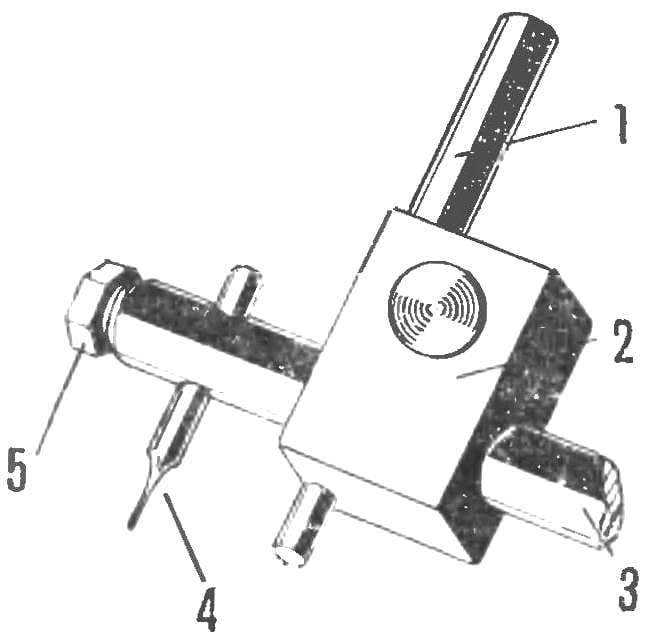

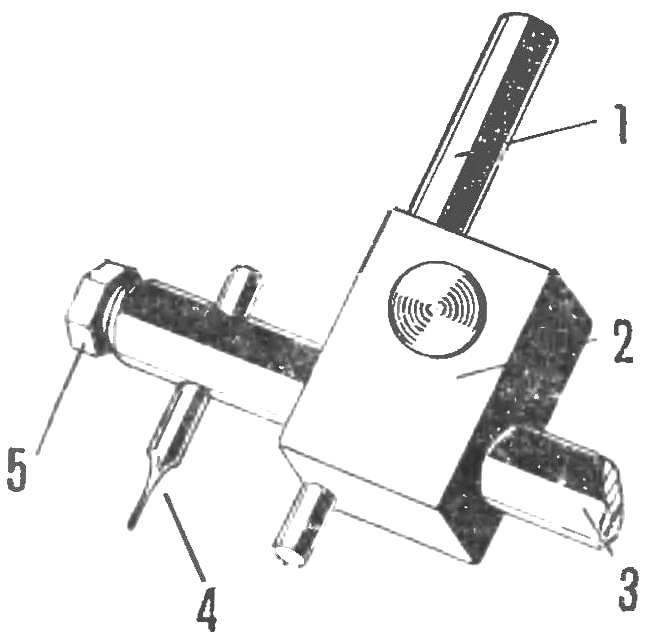

Universal cutter:

1 — chambered shank, 2 — head, 3 — horizontal pull-out rod, 4 — cutter, 5 — clamping screw.

Device (see Fig.) secured in the Chuck of the drilling machine, and a cutting element is clamped by the screw on the sliding horizontal bar: it allows to obtain a wide range of hole diameters. Depending on the “cut out” of the material, whether rubber, abrasive cloth, metal or plywood sheet or even glass as a cutting element, you can insert the cutter plate, cutter or a glass cutter.

Such a flexible device greatly improves the productivity and the quality of the holes. Especially effective rubber cutter in small batch and unit production, where it avoids the need to manufacture expensive tooling.