The discs of the clutch are machined on a lathe also of steel 3. In the end grooves on the discs inserted rubber liners for elastic transmission of torque. One disk is mounted on the motor shaft, locking screw, and the other movable, placed on the moving shaft key drum. To each other, the disks are pushed by the spring. Its force should be between 5-8 kgs. To adjust the clamp can move the drive coupler on the motor shaft.

When the machine is assembled and adjusted, the drum is wrapped a strip of sandpaper of the desired grit. Tape length equal to the perimeter of the circumference of the drum plus 15 mm for fixing it in the groove.

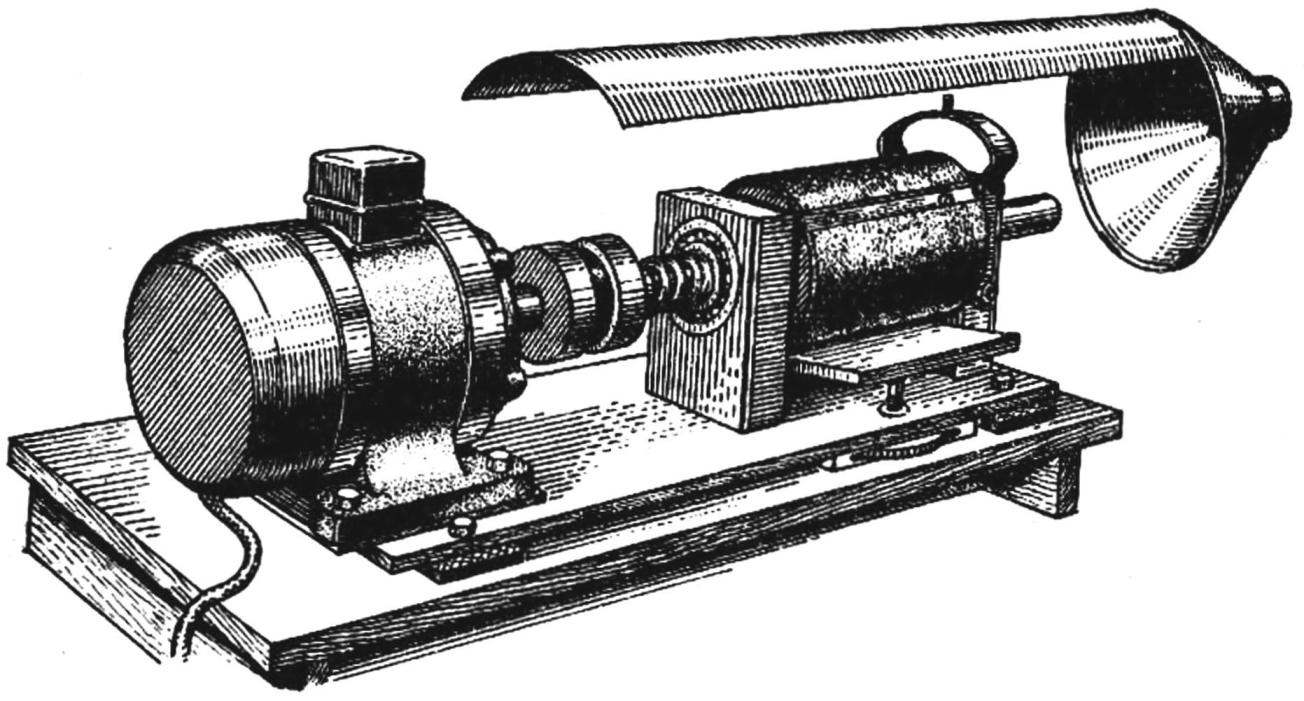

The layout details of the machine on the frame:

1 — snare, 2 — clamping strip, 3 — screw М6Х10. 4 — bearing housing, 5 — spring, 6, 8 — discs clutch, 7 — rubber earbuds, 9 — locking screw М4Х8, 10 — shaft, 11 — support frame, 12 — frame, 13 — working pad, 14 — axis of the working platform, 15 — bracket 16 — housing regulator, 17 — nut Adjuster, 18 — adjustment screw with a spherical head 19, screw М8Х15, 20 — holder of the adjusting bolt 21, the bearing 204 GOST 8338-57, 22 — a protective cover, W — holes for mounting the motor (mark the place), And is a place for the magnetic actuator, the connection of the vacuum cleaner.

The thickness of the layer of wood, remove when sanding in a single pass, depends on the type of skin and set the adjusting nut. The working platform turning about a fixed axis, is raised or lowered.

To the network three-phase AC machine connected as usual through a magnetic starter with pressure switch.

The rotating parts of the machine for security purposes, it is desirable to protect a protective cover. To make it out of tin or thin aluminum sheet. Produced by grinding waste are sucked out of the exhaust of the stationary device. Where it is not, you can use household cleaner.

E. MAKLETSOV, P. TRESKUNOV, Alma-ATA

Recommend to read

IN THE LANGUAGE OF DOTS AND DASHES

IN THE LANGUAGE OF DOTS AND DASHES

It's tempting to assemble a simple Telegraph device and to communicate using Morse code. Reliable two-way communication is needed in the conduct of military sports games and... “Pioneer” – karts for beginners

“Pioneer” – karts for beginners

The Pioneer class kart is the smallest of the sports racing cars. The working volume of its engine is only 50 cm 3 . Such karts are built for races in which children aged 9 to 16 years...

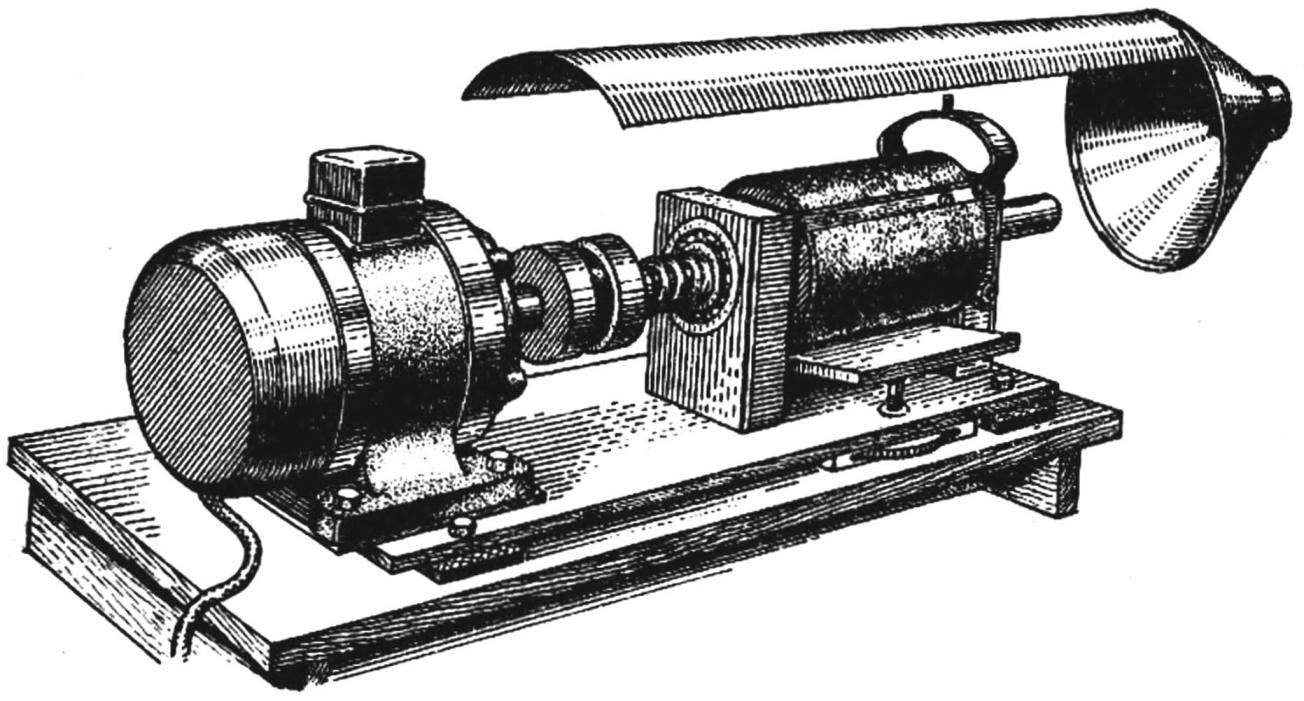

In technical circles often there is a need for a wooden workpiece, having a flat, smooth surface. To ground the Board easy manual processing is laborious and requires specific skills. The machine, designed in the laboratory, missile and space simulation CSUT of the Kazakh SSR, allows to mechanize the grinding of wooden parts. The design of the machine is clear from the figure. Used to the drive motor of the brand AOL-21-4 power of 0.27 watts at 1400 rpm, but you can use any other motor with similar characteristics.

In technical circles often there is a need for a wooden workpiece, having a flat, smooth surface. To ground the Board easy manual processing is laborious and requires specific skills. The machine, designed in the laboratory, missile and space simulation CSUT of the Kazakh SSR, allows to mechanize the grinding of wooden parts. The design of the machine is clear from the figure. Used to the drive motor of the brand AOL-21-4 power of 0.27 watts at 1400 rpm, but you can use any other motor with similar characteristics.