Mogilev plant “electric Motor” produces handy and compact machine “Skillful hands”. It can be cut into strips of the desired size sheet getinaks, textolite, plexiglass, plywood — any non-metallic materials with thickness up to 6 mm; sharpening of wood details round shape with a diameter of 40 mm and a length of 130 mm; sharpening drills of small diameters, screwdrivers, chisels, knives and other tools; polishing small flat and round metallic and non-metallic parts.

Mogilev plant “electric Motor” produces handy and compact machine “Skillful hands”. It can be cut into strips of the desired size sheet getinaks, textolite, plexiglass, plywood — any non-metallic materials with thickness up to 6 mm; sharpening of wood details round shape with a diameter of 40 mm and a length of 130 mm; sharpening drills of small diameters, screwdrivers, chisels, knives and other tools; polishing small flat and round metallic and non-metallic parts.

But the range of works produced on it can be further expanded. It showed the experience of using machines in the design office of the enterprises Saratovneftegas. There is a section of three-dimensional design of industrial enterprises and other objects not graphically, but with the help of engineering models, perform in a certain scale for natural values. Designers machine “Skillful hands” is also very useful.

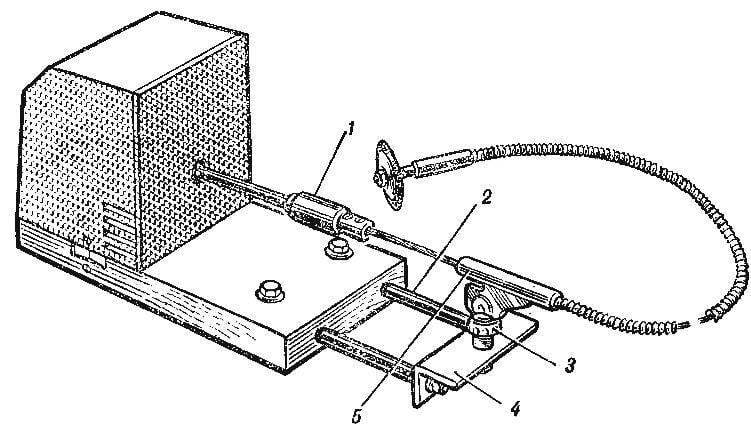

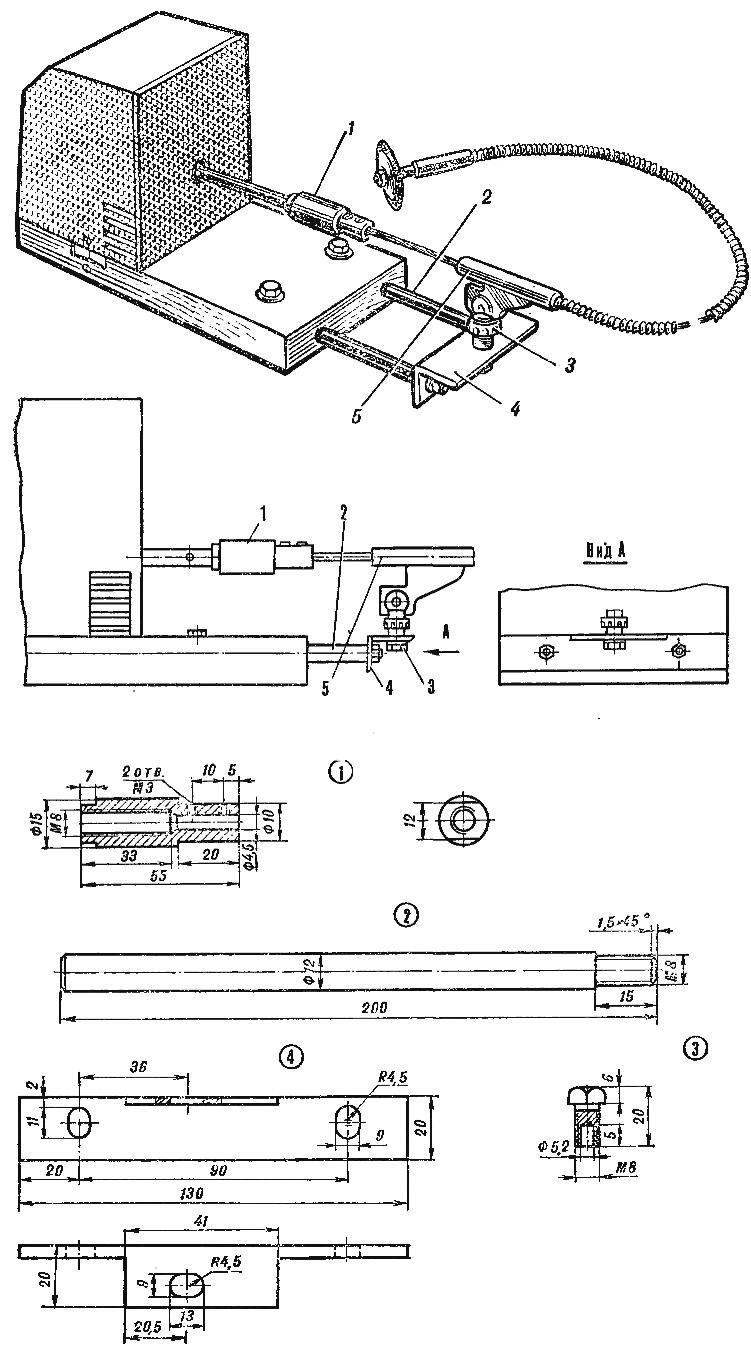

* The reason KB to the existing fixtures have produced additional, allowed to drill holes with diameter up to 3 mm in hard to reach areas and also perform the engraving work needed when creating layouts. To “that uses a flexible hose from the drill tip for clamping of drills and microres attached to the machine with parts, ka is shown in figure 1. They are all easy to manufacture the connection sleeve, two guides and an area for attaching a flexible hose. These details make the machine more versatile.

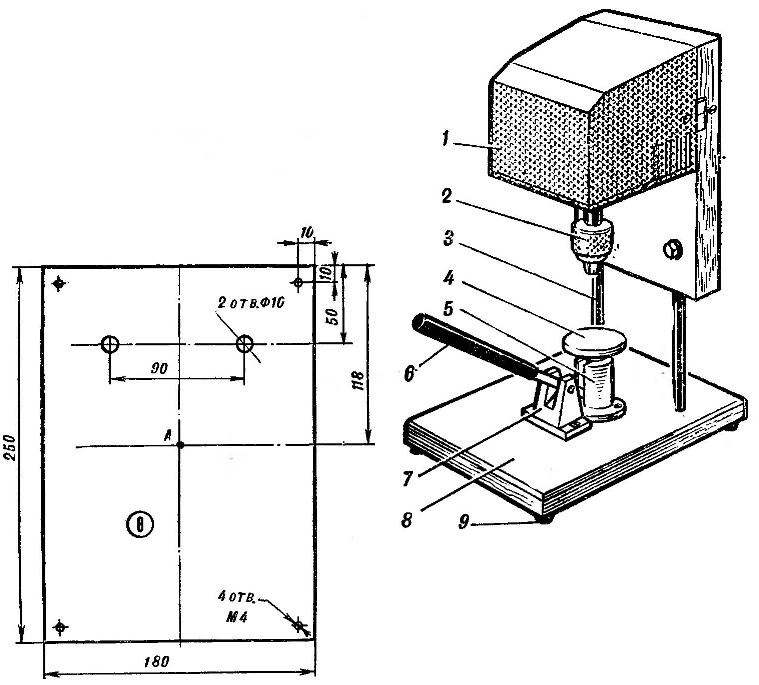

Fig. 1. Attachment to the frame of the “Skillful hands”:

1 — connecting bushing, 2 — rail, 3 — bolt flexible shaft, 4 — corner bracket, 5 bracket.

We offer manufacturer machines “Skillful hands” to consider the improvement of the innovators of our design office and included in the set is made of additional details.

Ya AMIGOT, Department head at KB enterprises Saratovneftegas

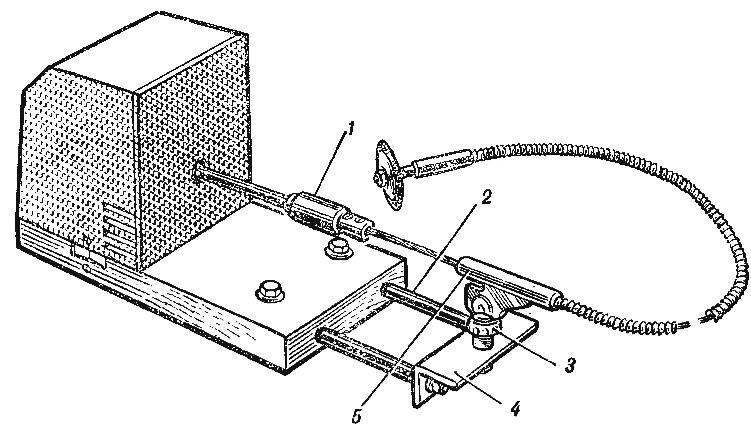

Press “Skillful hands” enjoy a good fame among those who love tinkering. But the number of operations he has limited. I propose an option of finishing machine, with which it becomes convenient for vertical drilling (Fig. 2).

Fig. 2. “Skillful hands” — the vertical option:

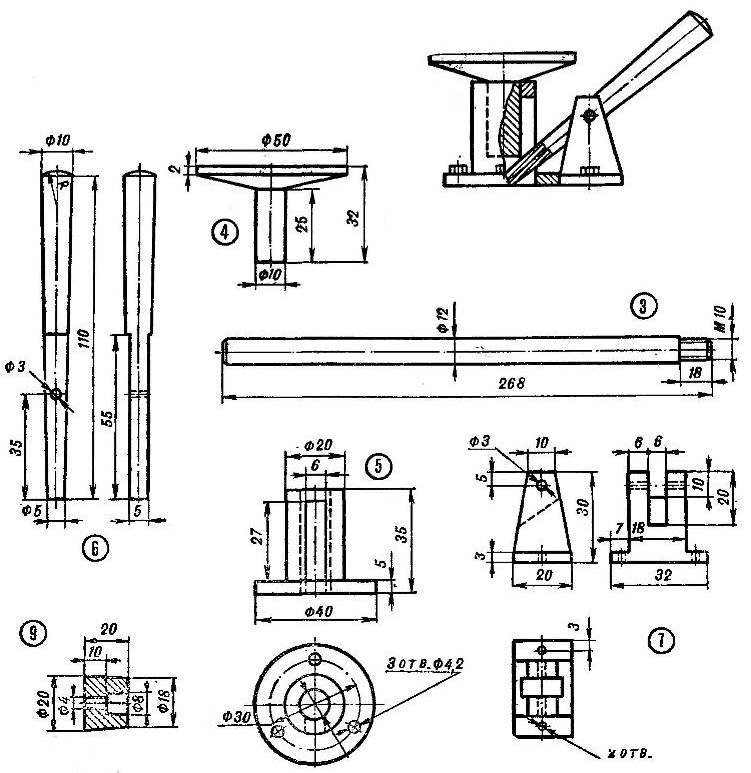

1 — machine 2 — Chuck of the drill, 3 — rail, 4 — lifting table, 5 — guiding bushing table 6 — lever 7 — a support of the lever, 8 — tab, 9 — foot.

With a hacksaw, cut off part of the motor shaft length of 60 mm. Then the machine is switched on and the end of the rotating shaft with a file grinds to a cone under the drill Chuck.

The cartridge can be take from old hand drill. When drilling unlike conventional machines, the detail is coming to the drill. This is made simple lifting of the feet (figure 3) served up a small lever.

The backbone of the machine serves as a Board in the drawing, holes are drilled for the legs and rails of the lift table. Axis point table on the Board is easy to determine, lowering the working part of the machine along the guide rails until it stops drill spin.

Fig. 3. Diagram of the feed mechanism.

All cylindrical parts made on a lathe; the groove in the guide table is milled and the support arm can be pierced and a file. The shank of the lifting table and grind the hole of the guide sleeve and lubricate periodically.

Those who are interested in new opportunities in the modernization of the machine, I would like to suggest to consider a completely new design lifting table, which could ensure consolidation of the workpiece.

V. RAZAKHATSKAYA, Brest