The spindle head is composed of parts, easily machined on a lathe: housing, spindle, melodiewinawer rings, clamping nut and multi-strand pulley.

The spindle is hollow steel shaft is revolved by electric motor through V-belt transmission by means mounted on the keyway on the pulley. The working shank of the spindle has an internal taper overschie under No. 2, and the outer diameter of the thread RESPECTED. This gives you the ability to set the tool with an ionic shank drill bits, reamers, core drills, boring heads, collets, drill chucks, and with the adapter flange and rim — lathe chucks, faceplate, grinding wheel, polishing wheels, ceramic cutting disk cutter the saw.

Of course, the most effective use of these tools will require some adaptations. Thus, when the vertical orientation of the spindle for performing drilling operations it is desirable to use machining vise. When drilling small parts it is more convenient to use a Desk lever or gear type.

Greatly expand the functionality of the machine application of the coordinate table with a fortified it by the machine vise. Due to the presence of two mutually perpendicular to the lead screw of the part, clamped in a Vice, it will be possible to shift relatively to the rotary tool in two directions (in two coordinates). This will allow for vertical layout to perform milling, and horizontal, holding the item in the Chuck, and the cutter — vise — lathe. To sharpen details of considerable length and to process solid materials: steel, cast iron, bronze, on the table you can fasten the tailstock, and the caliper to be equipped with additional sliding bar, fastened at the base.

Fig. 3. Power host machine:

1 — a pulley of the motor, 2 — motor N — 180 W, n = 1380 rpm, 3 — plate engine mounts, 4 — base plate bracket, 5 — V belt, 6 — a pulley of the spindle.

Fig. 4. A set of basic tools to the machine-universal:

1 — collet draw bolt, 2 — tool taper shank, 3 — setting tool through the transition cone, 4 — drill Chuck on a tapered mandrel, 5 — the Chuck with the transition flange, 6 — disc mill, 7-10 tools with cylindrical shank: drill bit, core drills, reamers, boring heads, etc., 11 is a mandrel for mounting sanding, wire, buffing wheels, 12 — cylindrical mandrel for pressing.

To turn the machine in a circular saw, you can use simple U-shaped table, bent from steel or dural sheet with a thickness of 2 mm.

various household mechanisms: engraving installation, mixer, winding machine, spinning wheel and even to help the hostess — the grinder and the shredder!

The base of the machine with vertical feed mechanism can perform another “moonlighting”: when replacing a spindle head, a simple cylindrical mandrel turns out powerful enough press, which is useful in Assembly operations, and the bonding and vulcanization.

Noi is not limited to this list of capabilities of the machine. Simple devices allow to produce it armored mesh, to carry out rolling through the simple and contoured rollers or replacing rollers on circular blades — slitting sheet materials.

In addition, on the basis of this machine is designed and tested in the original design pantografos copy of the installation, ensuring microreserve any profiles, inscriptions and images on the copier with a scale reduction from 1 :1 to 1 :50!

Y. ORLOV, R. MAY, Troitsk, Moscow region

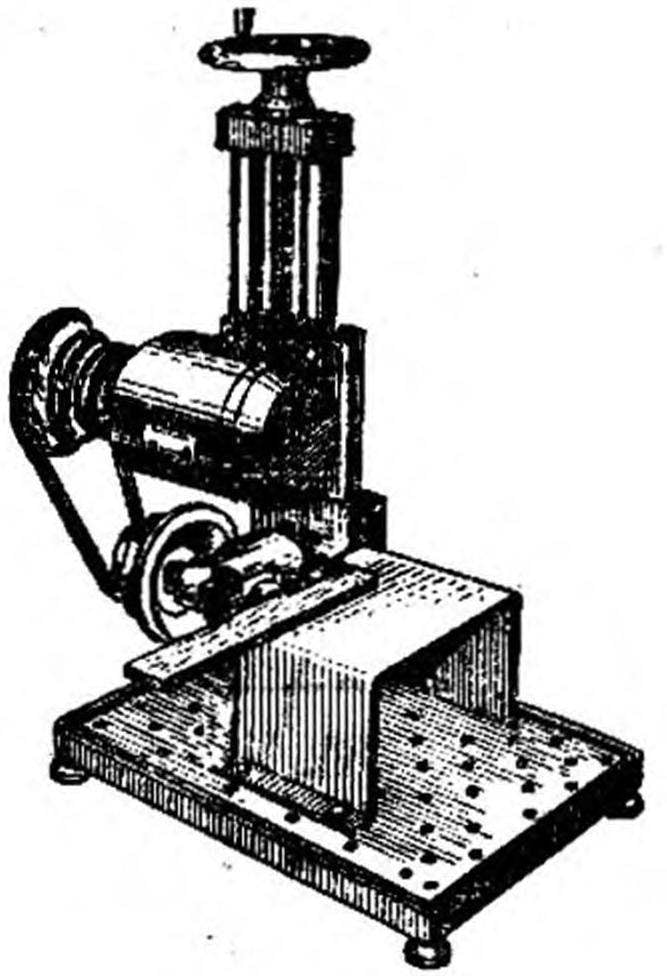

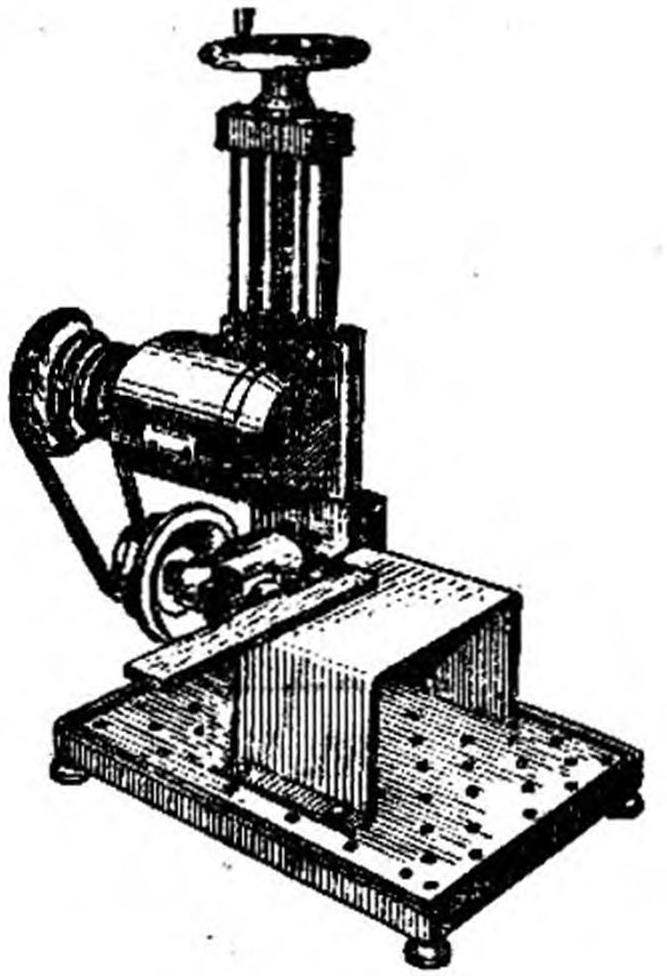

In one of the shows can viewers was submitted to design a universal machine, designed by the engraver of the suburban town of Troitsk Y. M. Orlov. Not only a discussion of a design program participants, but also by the numerous letters received by the author, editions, TV and the magazine “M-K” showed how great the interest was this table versatile machine capable of performing a number of operations for machining a variety of materials. To meet numerous requests, the editors asked the author designs to tell more about it.

In one of the shows can viewers was submitted to design a universal machine, designed by the engraver of the suburban town of Troitsk Y. M. Orlov. Not only a discussion of a design program participants, but also by the numerous letters received by the author, editions, TV and the magazine “M-K” showed how great the interest was this table versatile machine capable of performing a number of operations for machining a variety of materials. To meet numerous requests, the editors asked the author designs to tell more about it.