Yes, on any lathe with a hollow spindle it is possible navit spring diameter up to 12 mm from the wire thickness of 0.1 to 2 mm. More than that — of any length. All this is provided by a simple device introduced by NTTM participants at the Leningrad order of the red banner of Labour plant of lifting and transportation equipment named after S. M. Kirov. Unlike similar devices, there’s a knot in the wire feeding thanks to the ingenious solution available for self-production in rural workshops.

Yes, on any lathe with a hollow spindle it is possible navit spring diameter up to 12 mm from the wire thickness of 0.1 to 2 mm. More than that — of any length. All this is provided by a simple device introduced by NTTM participants at the Leningrad order of the red banner of Labour plant of lifting and transportation equipment named after S. M. Kirov. Unlike similar devices, there’s a knot in the wire feeding thanks to the ingenious solution available for self-production in rural workshops.

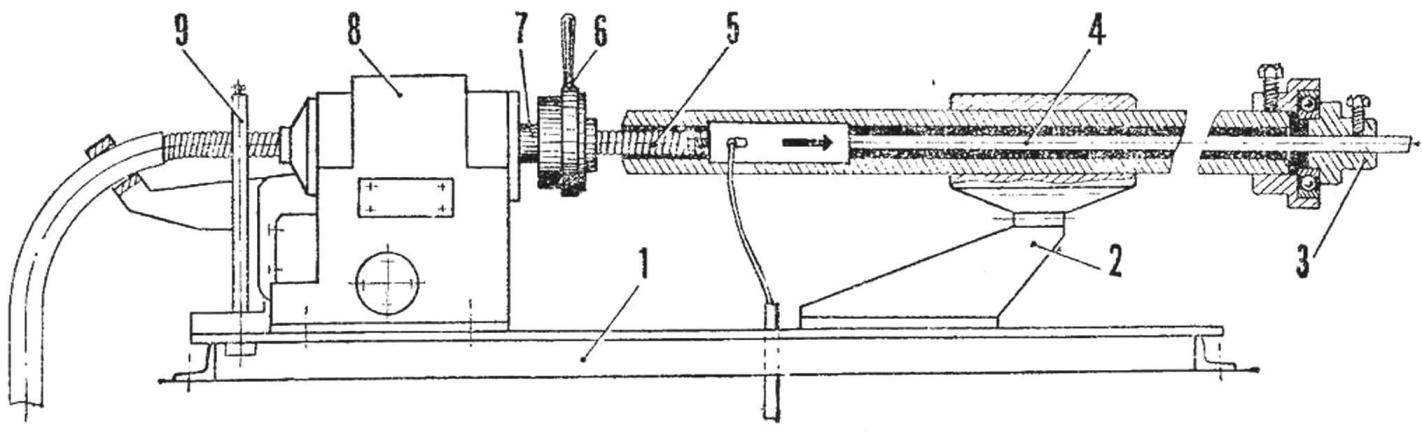

The main detail of the fixture — pipe with a longitudinal groove. It is attached to the back of the headstock of the machine or in the bracket mounted on the frame, equipped with a front pastern and is equipped with the engine.

In a longitudinal groove of the pipe guide is inserted in the Shuttle to the hub, the diameter of which is slightly smaller than the inner diameter of the pipe. This allows the Shuttle to move freely along the groove. Through the canoe at an angle to the axis of its sleeve skipped a feeding tube through which is passed the wire. She and circumferential to the rod-holder, passing inside the tube through the grommet of the Shuttle. Depending on the desired diameter made of a spring rod can be used also with different diameters. At one end it is fastened in the sleeve, mounted movably on the bearing, at the end of the pipe. And the other is clamped together with the end of the wire in the collet Chuck of the lathe headstock. Collets can also be replaced depending on the chosen diameter of the core mandrel.

The device works in the following way. Handle cartridge divorced collet and clamped the mandrel with the end of the wire is passed through the Shuttle. When the engine is turning through the reducer, providing on the spindle 530, 760, 990 and 1420 rpm, the wire begins to be wound on the mandrel, each new round rests in the sleeve of the Shuttle, moving it along the tube and thereby providing a uniform winding of new turns.

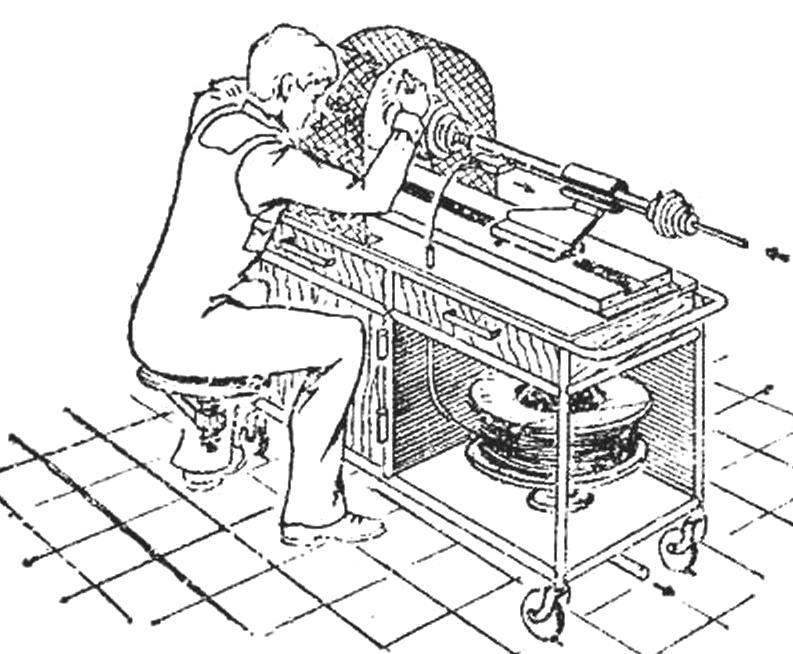

A device for coiling springs:

1 — frame, 2 — tailstock, 3 end bushing, 4 — stem-mandrel, 5 — wound spring 6 — grip collet Chuck, 7 — spindle, 8 — reducer, 9 — chopping device

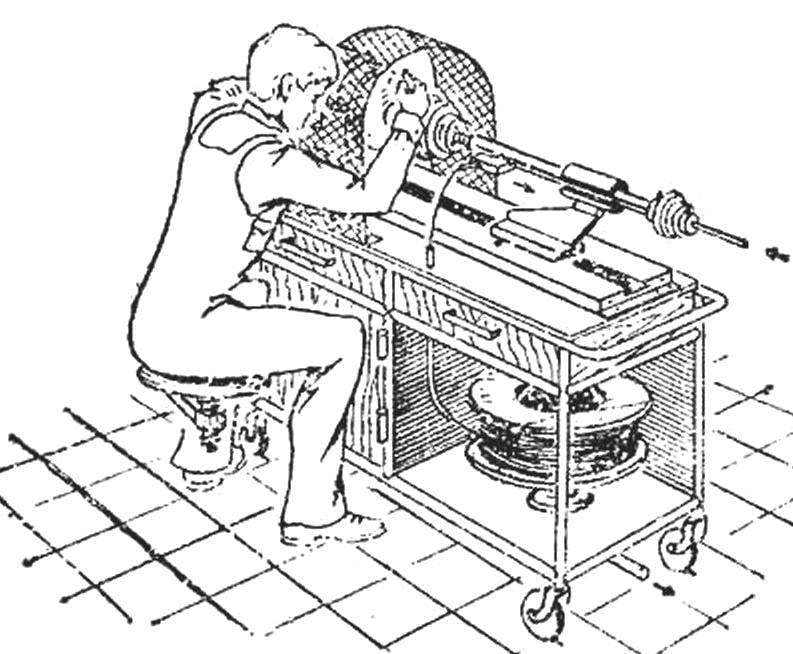

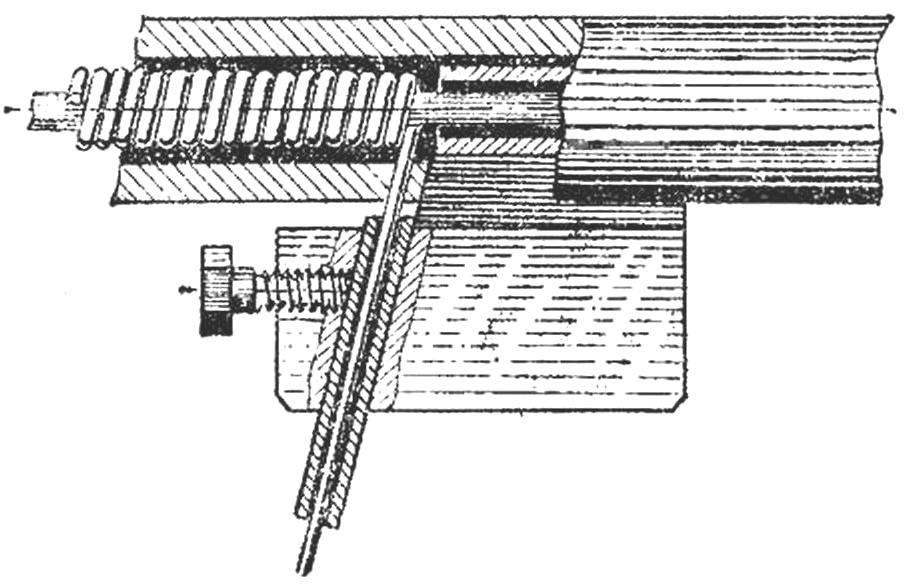

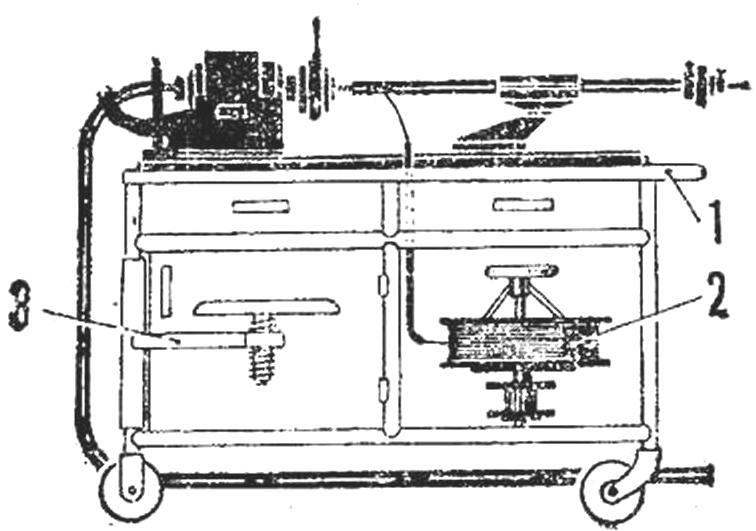

Table trolley with device:

1 — pen, 2 — drum with wire 3 slide — out chair.

After sinking the canoe, just PA for the pipe-rail turn the Chuck collet are released, the spring unwinds slightly and hook shifted through the hollow spindle, easy on the mandrel. Then handle the cartridge are clamped by the collet again, and the cycle repeats, Thanks to the length of the wound spring can be unlimited If required, is also possible to cut off the spring the right length — it is to the left of the engine there is a special chopping device.

In addition to using the fixture on a lathe, we can also produce special simple spring coiling table, an equipped, in addition to all the basic elements, and even a pull-out chair and a feeding drum with a wire.

The introduction of such devices greatly increases productivity, improves product quality and provides a considerable economic effect.