If you have a rectifier for charging automobile batteries, a step-down transformer or Latr you will be able to make thermoresin cutting foam. The cutting part is a piece of nichrome wire mounted on a handle of insulating material. Device tool shown in figure 1.

If you have a rectifier for charging automobile batteries, a step-down transformer or Latr you will be able to make thermoresin cutting foam. The cutting part is a piece of nichrome wire mounted on a handle of insulating material. Device tool shown in figure 1.

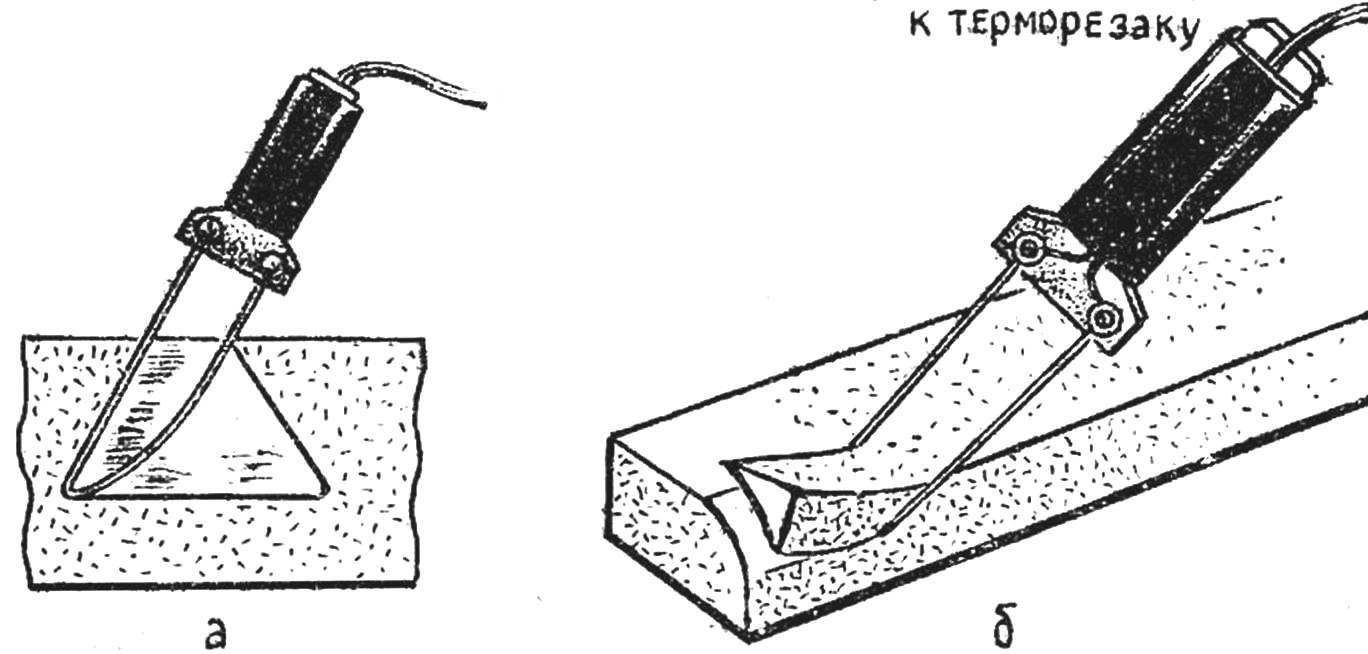

Thermoresin allows you to make grooves, carve a cavity in the thickness of the material and all contact with the foam as sculptor would with clay. After this treatment the surface is a thin fused crust, which increases the stiffness and strength of the foam and closing its pores.

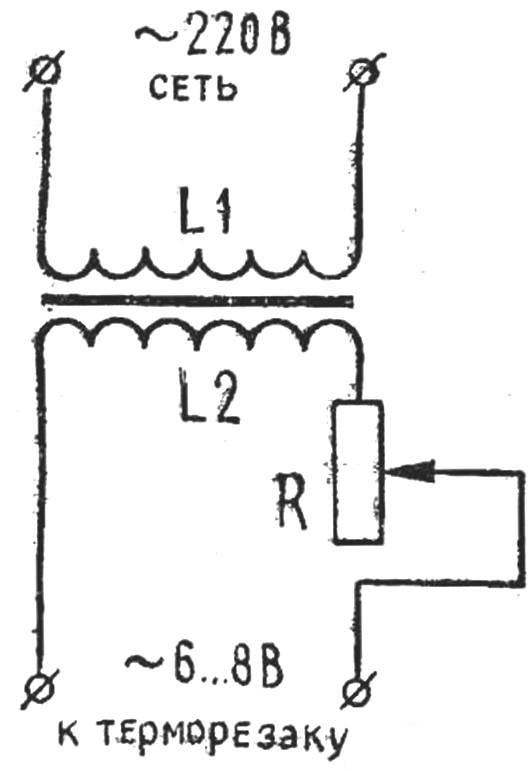

Step-down transformer Molen to do it yourself. This will require a transformer iron Ш20Х24. The primary winding has 1600 turns of wire of brand of PEV-1 0.39 in (or PEV-1 is 0.44), and the secondary is 50 turns of wire of the same brand and thickness 1,0—1,1 mm. For choosing the value of the current, make the resistor (it would suit a pre-stretched helix from electric).

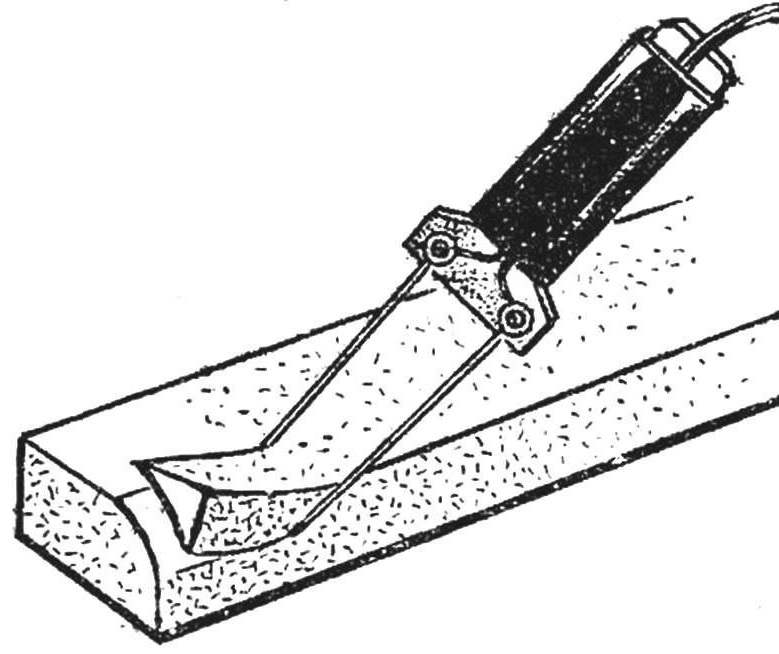

Fig. 1. Device Thermaltake:

1 — nichrome wire (the spiral electric), 2 — screw with nut and washer 3 — handle (4 mm PCB’s), 4 — cable, 5 connector, 6 — rubber or vinyl chloride tube.

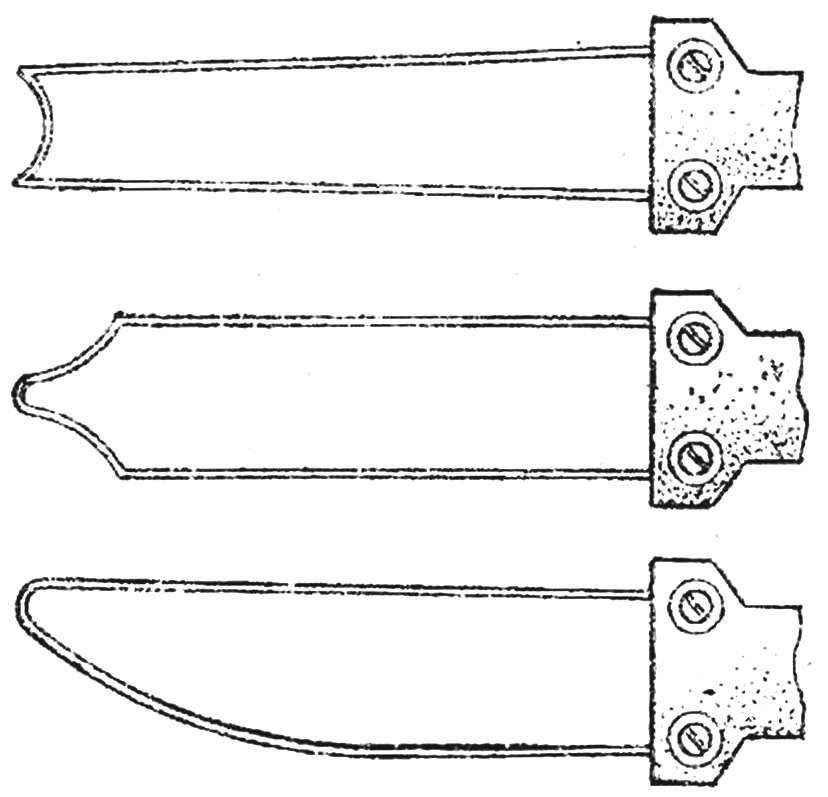

Fig. 2. Options wire tips to Thermaltake.

Fig. 3. Connection diagram step-down transformer and the rheostat.

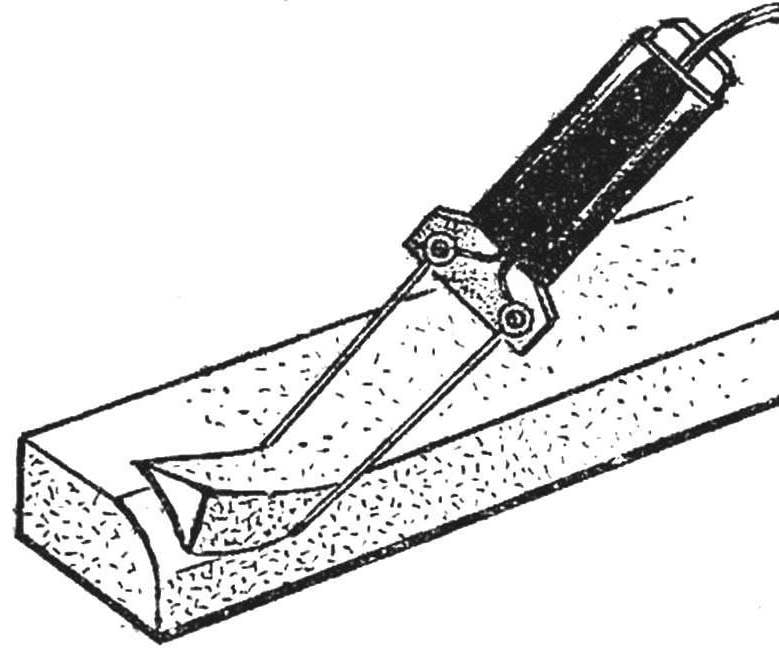

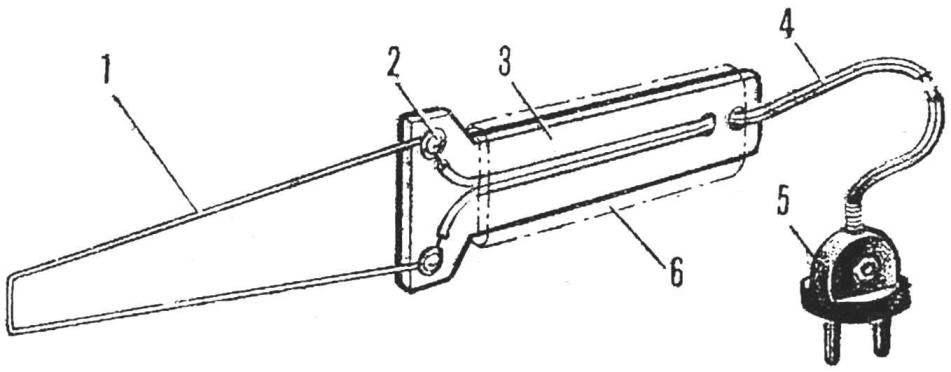

Fig. 4. Some techniques work thermoresistor:

a — the formation of the cavity, b — chamfering.

For the armature coil use a suitable asbestos or ceramic tube Ø 10-15 mm and a length of about 80 mm. to Wind nichrome wire to fill the frame.

If you seriously are addicted to cutting curly foam, it makes sense to prepare several of these cutters (Fig. 2) with different tips.

V. DRUZHININ, Novokuznetsk