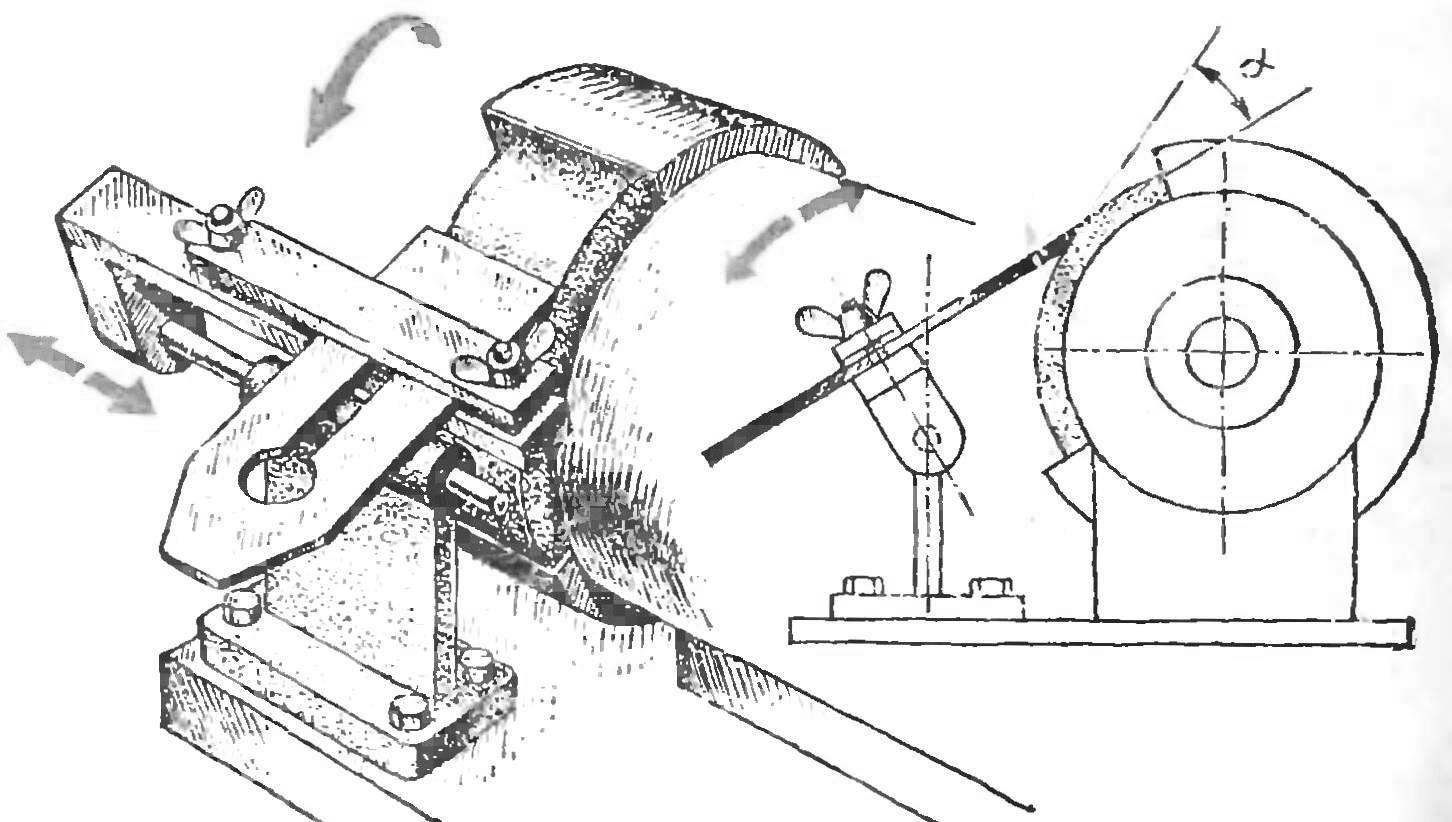

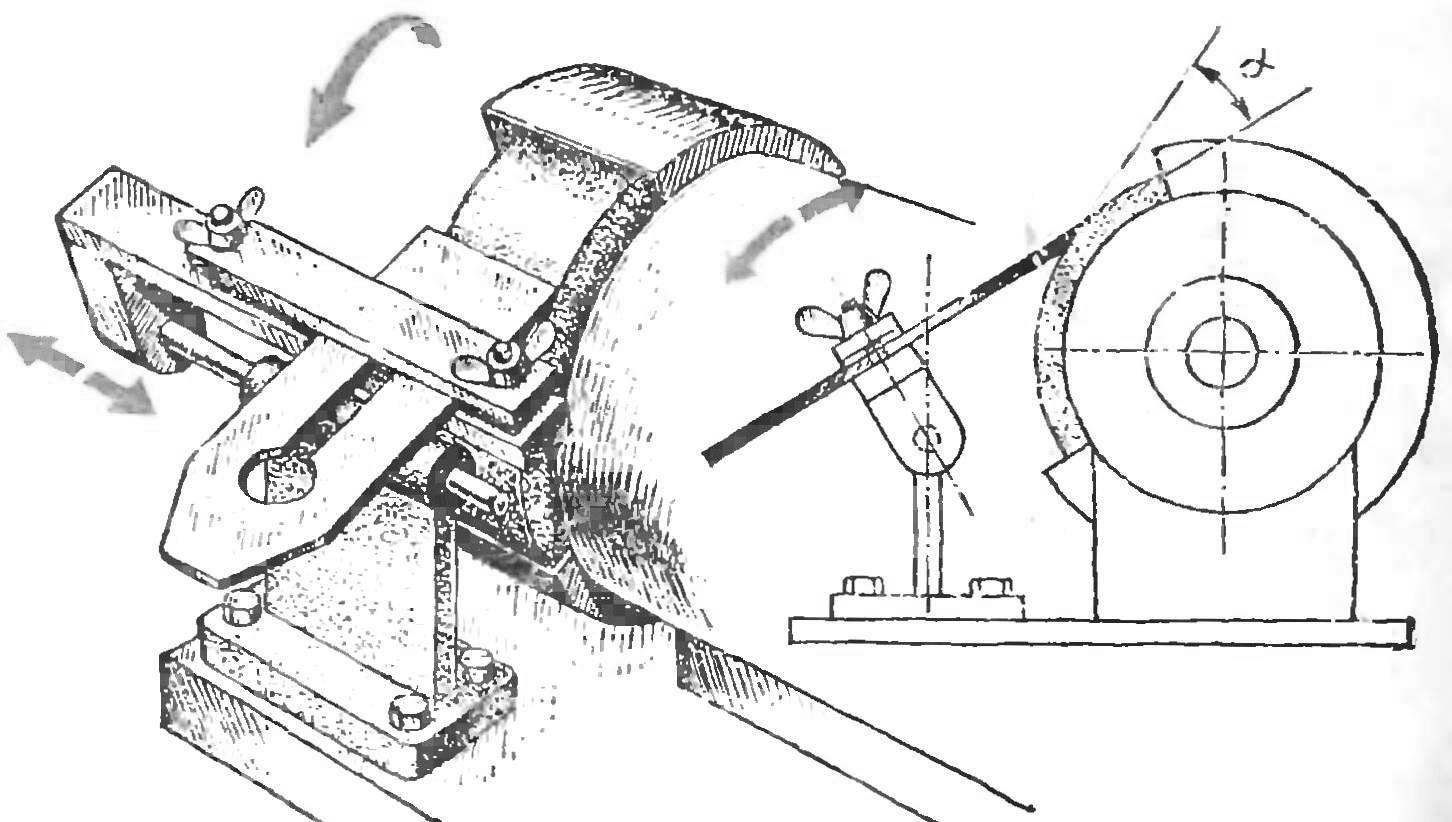

Reground the blade plane for beginners is sheer torture. Not so just manually set the correct angle between the sand around and a piece of iron and withstand this angle throughout the sharpening process. Vladimir Voskresenskiy made for such cases a simple device for sharpening. To the T-shaped rack he welded the bushing and installed the node in place of the armrest. In the sleeve is free to move the roller, which is connected via an adapter with a ruler — steel strip with a thickness of 5 mm. To the last two wing screws attached to the strip-lock. The device works in the following way. Tool — the blade of the planer, the chisel or the chisel is clamped between ruler and strip-clamp so that the angle between the tangent to the abrasive stone and the plane of the instrument was equal to approximately 10° Then turn the grindstone and moving piece of metal right and left due to the free motion of the roller, remove the excess layer of metal from the blade. After this treatment, it is already difficult to fill on the touchstone.

Recommend to read

GAZ-415

GAZ-415

Pickup GAZ-4 in the Soviet Union enjoyed a well - deserved popularity - it acquired trading bases, small businesses and cooperatives. In 1936, at the Gorky automobile plant is the GAZ-A,... BAIT AND HUNTERS

BAIT AND HUNTERS

Only six months after the outbreak of the First world war Britain, the strongest Maritime power, it seemed, had no rivals on the oceans, was in dire Straits. New, not taken seriously...

Reground the blade plane for beginners is sheer torture. Not so just manually set the correct angle between the sand around and a piece of iron and withstand this angle throughout the sharpening process. Vladimir Voskresenskiy made for such cases a simple device for sharpening. To the T-shaped rack he welded the bushing and installed the node in place of the armrest. In the sleeve is free to move the roller, which is connected via an adapter with a ruler — steel strip with a thickness of 5 mm. To the last two wing screws attached to the strip-lock. The device works in the following way. Tool — the blade of the planer, the chisel or the chisel is clamped between ruler and strip-clamp so that the angle between the tangent to the abrasive stone and the plane of the instrument was equal to approximately 10° Then turn the grindstone and moving piece of metal right and left due to the free motion of the roller, remove the excess layer of metal from the blade. After this treatment, it is already difficult to fill on the touchstone.

Reground the blade plane for beginners is sheer torture. Not so just manually set the correct angle between the sand around and a piece of iron and withstand this angle throughout the sharpening process. Vladimir Voskresenskiy made for such cases a simple device for sharpening. To the T-shaped rack he welded the bushing and installed the node in place of the armrest. In the sleeve is free to move the roller, which is connected via an adapter with a ruler — steel strip with a thickness of 5 mm. To the last two wing screws attached to the strip-lock. The device works in the following way. Tool — the blade of the planer, the chisel or the chisel is clamped between ruler and strip-clamp so that the angle between the tangent to the abrasive stone and the plane of the instrument was equal to approximately 10° Then turn the grindstone and moving piece of metal right and left due to the free motion of the roller, remove the excess layer of metal from the blade. After this treatment, it is already difficult to fill on the touchstone.

Reground the blade plane for beginners is sheer torture. Not so just manually set the correct angle between the sand around and a piece of iron and withstand this angle throughout the sharpening process. Vladimir Voskresenskiy made for such cases a simple device for sharpening. To the T-shaped rack he welded the bushing and installed the node in place of the armrest. In the sleeve is free to move the roller, which is connected via an adapter with a ruler — steel strip with a thickness of 5 mm. To the last two wing screws attached to the strip-lock. The device works in the following way. Tool — the blade of the planer, the chisel or the chisel is clamped between ruler and strip-clamp so that the angle between the tangent to the abrasive stone and the plane of the instrument was equal to approximately 10° Then turn the grindstone and moving piece of metal right and left due to the free motion of the roller, remove the excess layer of metal from the blade. After this treatment, it is already difficult to fill on the touchstone.

Reground the blade plane for beginners is sheer torture. Not so just manually set the correct angle between the sand around and a piece of iron and withstand this angle throughout the sharpening process. Vladimir Voskresenskiy made for such cases a simple device for sharpening. To the T-shaped rack he welded the bushing and installed the node in place of the armrest. In the sleeve is free to move the roller, which is connected via an adapter with a ruler — steel strip with a thickness of 5 mm. To the last two wing screws attached to the strip-lock. The device works in the following way. Tool — the blade of the planer, the chisel or the chisel is clamped between ruler and strip-clamp so that the angle between the tangent to the abrasive stone and the plane of the instrument was equal to approximately 10° Then turn the grindstone and moving piece of metal right and left due to the free motion of the roller, remove the excess layer of metal from the blade. After this treatment, it is already difficult to fill on the touchstone.