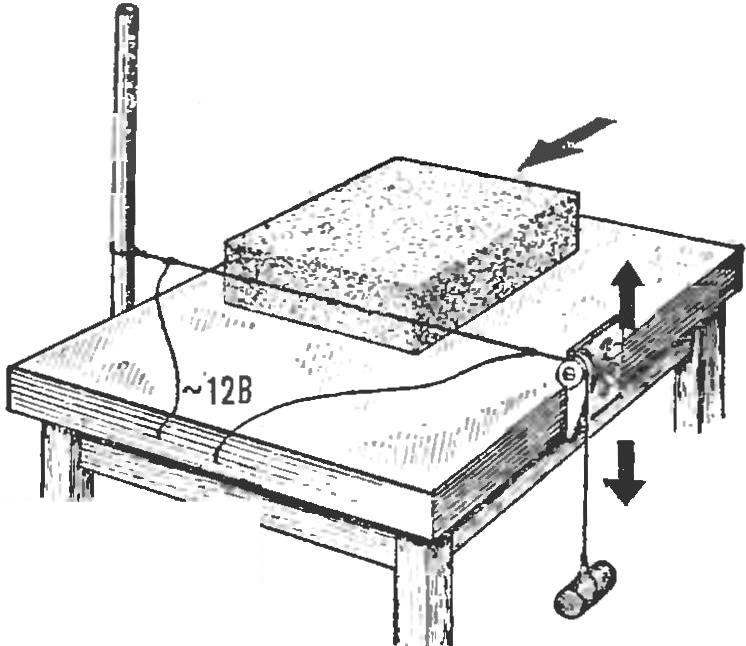

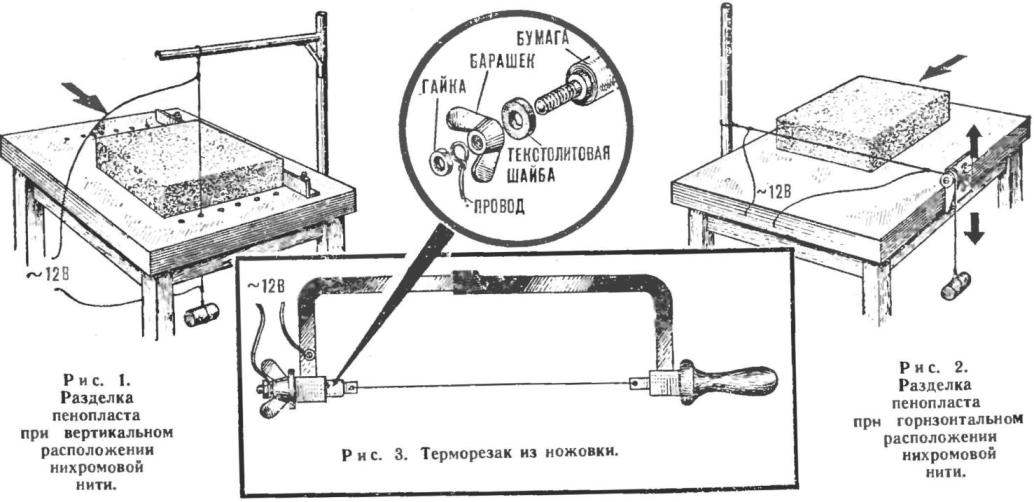

Offer two method of cutting large sheets of foam. Nichrome filament is suspended vertically (Fig. 1) or stretched horizontally to the table surface (Fig. 2). Adjusting in the first case, the distance from the filament to a movable guide area and the second the height and angle of the thread relative to the surface of the table, it is possible to obtain blanks of all shapes and sizes. The expansion of the filament during heating is selected with the cargo.

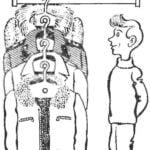

Offer two method of cutting large sheets of foam. Nichrome filament is suspended vertically (Fig. 1) or stretched horizontally to the table surface (Fig. 2). Adjusting in the first case, the distance from the filament to a movable guide area and the second the height and angle of the thread relative to the surface of the table, it is possible to obtain blanks of all shapes and sizes. The expansion of the filament during heating is selected with the cargo.

By changing the distance between the movable contact clamps (type “crocodile”), regulate the tension of the thread.

When working with small pieces of foam, there is no need to make a special frame for fixing the nichrome filament. For this you can use a regular jig saw or hacksaw, replacing a brush or cloth nichrome filament (Fig. 3). Thus it is necessary to carefully isolate the current-carrying contacts on them. The movable part of the cutter regulating the yarn tension, isolate from the case with asbestos or paper gasket and stretch a little lamb — the textolite washer.