Building solutions, lubricating oils, protective fluids, paint, varnishes for coating of many modern “self-leveling” materials require special spray tips.

Building solutions, lubricating oils, protective fluids, paint, varnishes for coating of many modern “self-leveling” materials require special spray tips.

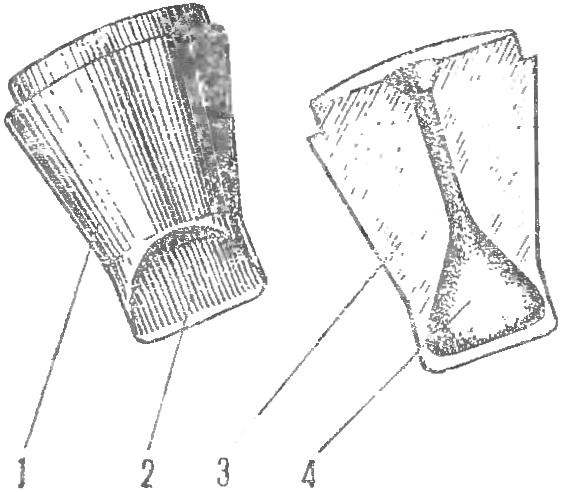

Original nozzle for these purposes were offered by participants NTTM Syzran plastics plant. Its appearance may even cause surprise: the supply hose ends of the metal tube. However, upon closer inspection, you notice that the tube split: it consists of two symmetrical halves. If you separate them, opens them formed by the internal cavity romboobrazny form.

Spray nozzle:

1 — half of the housing. 2 — bow, 3 — plane of the connector with channel 4 — cavity.

How do you work this nozzle? Raspylivatelja fluid is drawn into the housing is installed in the nozzle of the nozzle under pressure through a narrow channel tip. From here it enters the expanding dead-end part of the cavity, as if locking it in a closed space. In the “glass” creates a high pressure .liquid, which begins to inflate lapped halves of the “tube”. Formed microwell cross-section of 0.01 — 0.02 mm, which with great force and escapes the fluid: the spray gun is obtained, economical and precise. This type of nozzle not only improves the quality and efficiency, but also gives considerable savings — more than 12 thousand rubles per year.