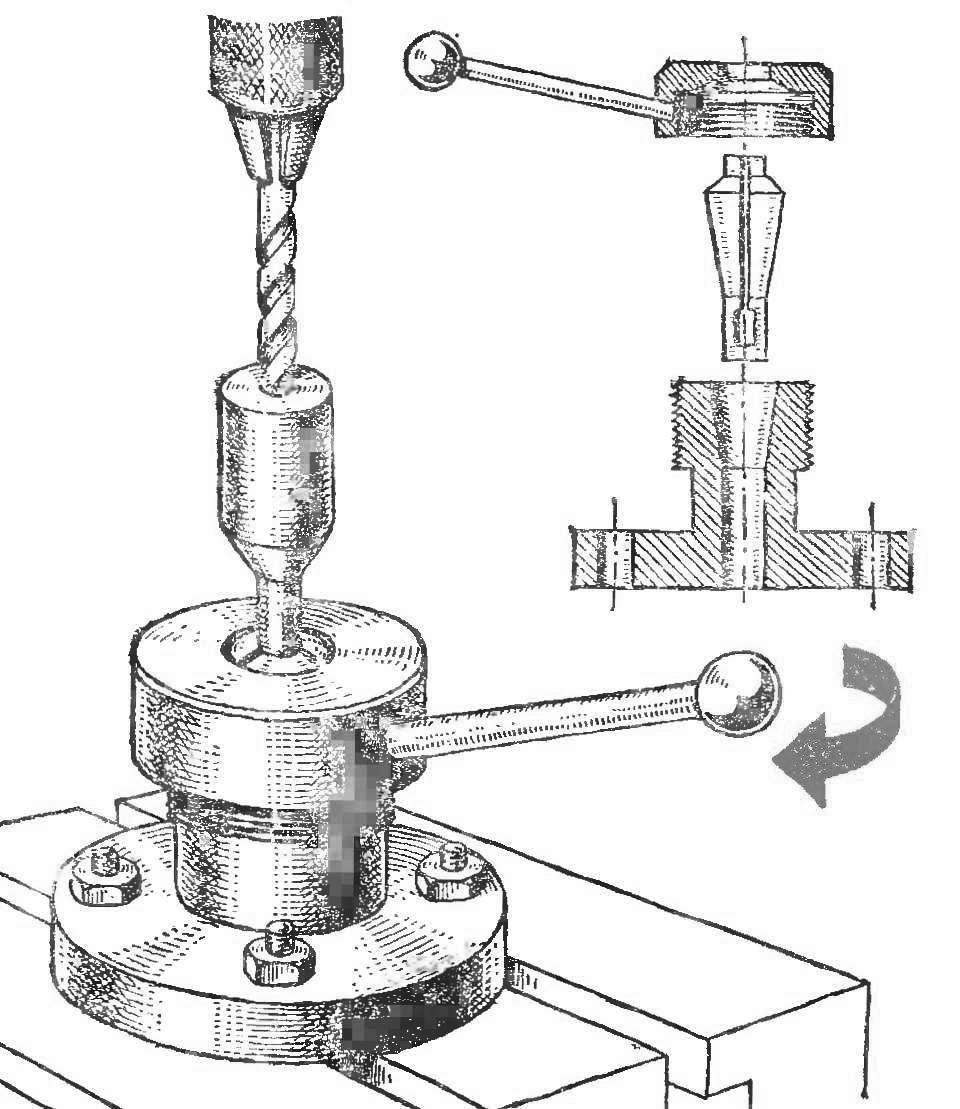

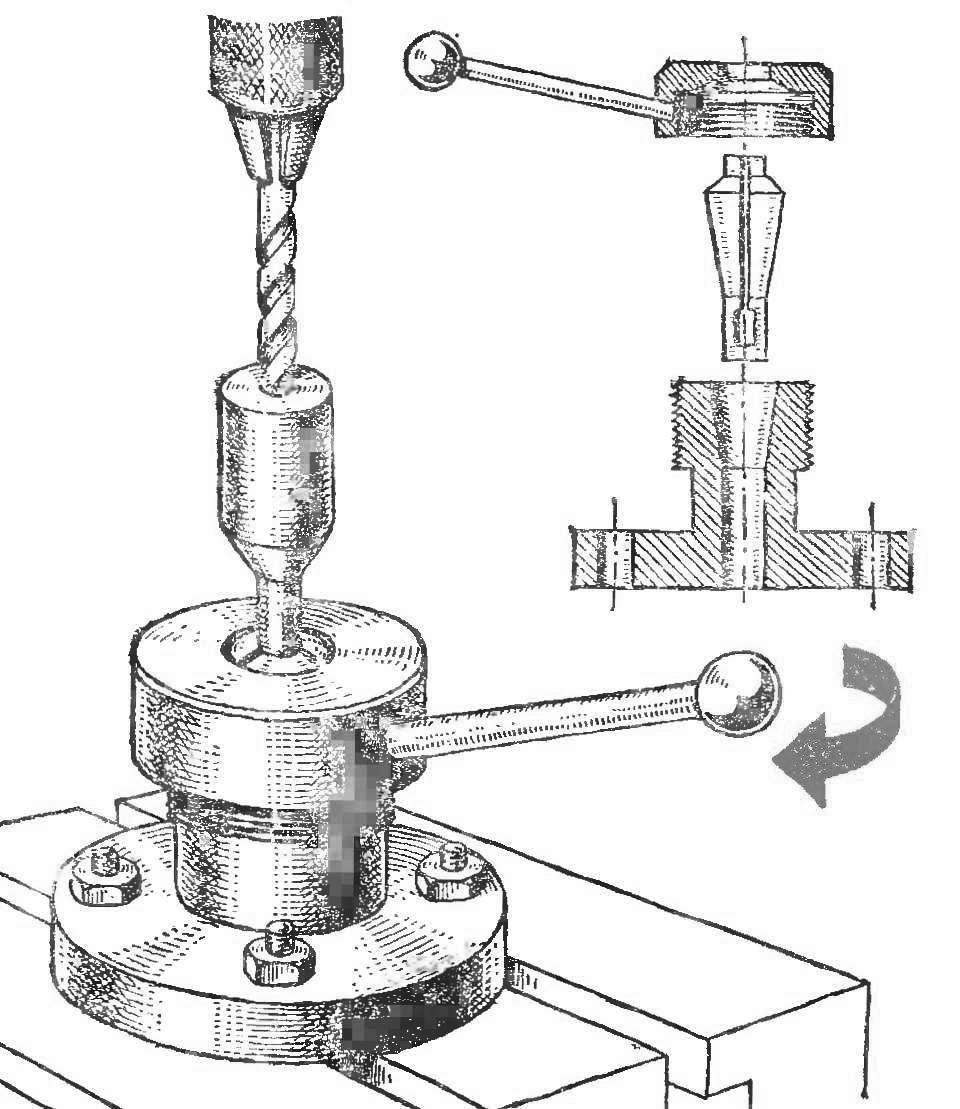

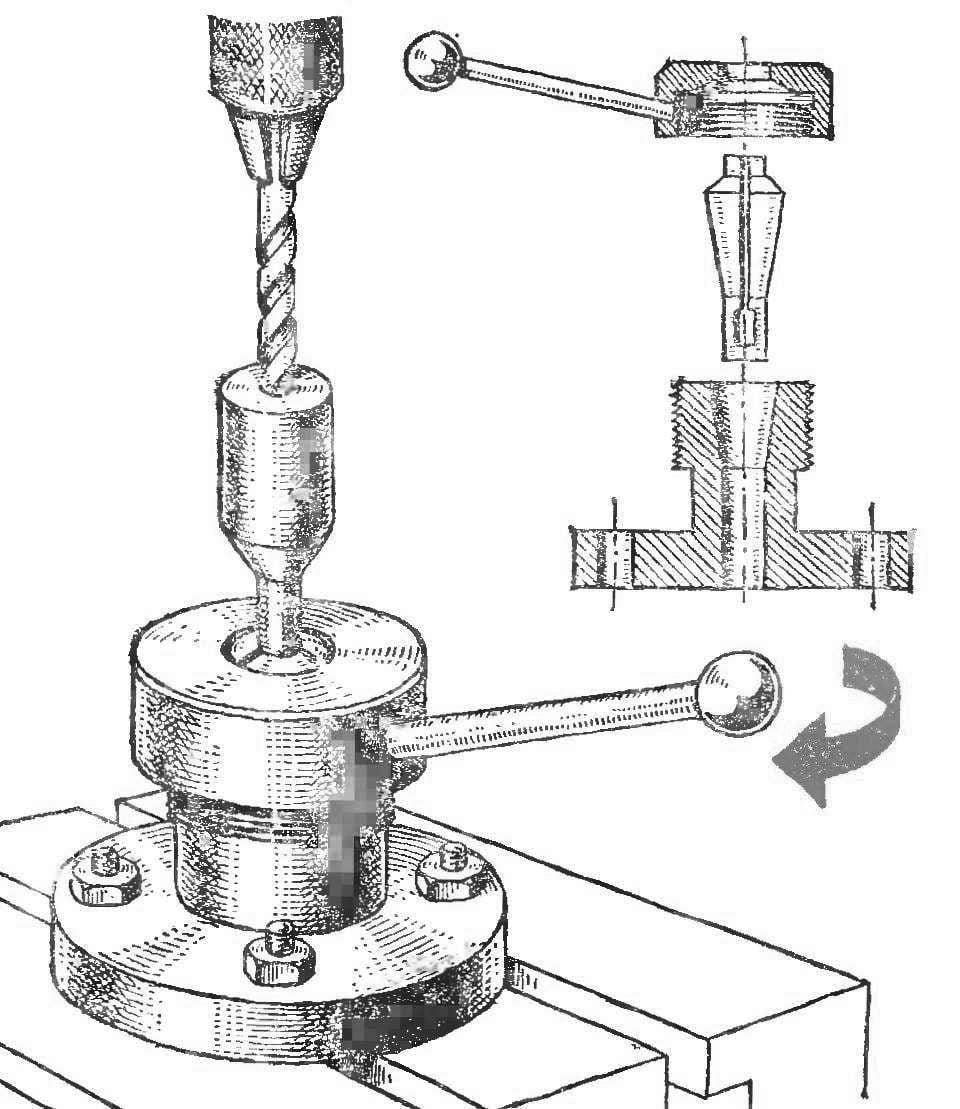

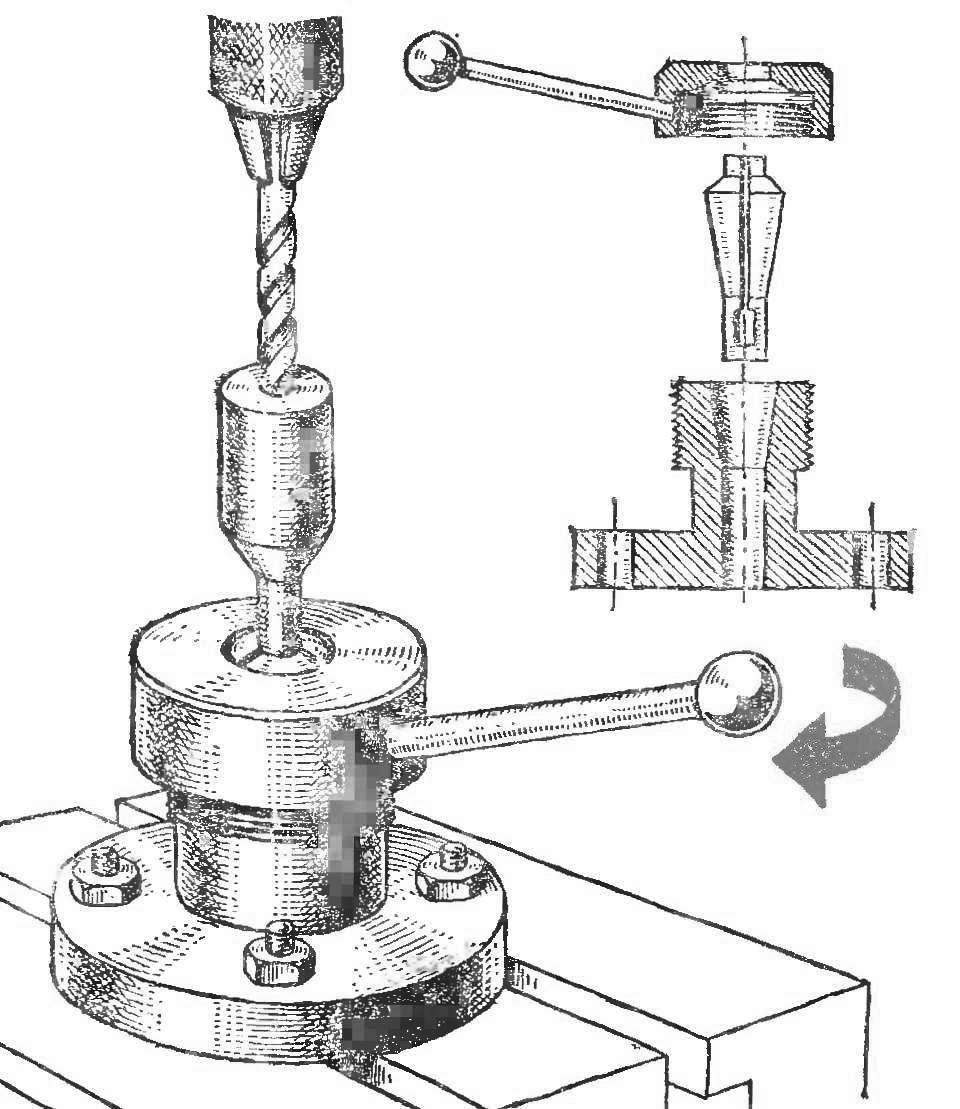

The simplest collet was developed by the students in the CPC Leninsky district of the city of Alma-ATA. It can be used quickly and reliably to clamp cylindrical parts, shafts, axles, bushings. The fixture base is a steel flange, the flat end of which drilled four holes, through which the clip is bolted to the table of the drilling or milling machine. On a cylindrical surface of circular cross-section, and accordingly the same has a thread on the clamping lid. Inside the flange is a machined hole, its taper must match the taper of the standard collets. On the clamping lid is arm. A set of standard collets allows you to record in the fixture parts of various diameters. The application of the clip and the code of criminal procedure allowed to significantly reduce the time of drilling bushings and completely to eliminate defects — holes in the bushings are now positioned exactly on their axis.

Recommend to read

“EIGHT” IN THE CIRCLE

“EIGHT” IN THE CIRCLE

Modern models of bikes full of new materials and technologies. But in most cases it touches the chassis, steering, powertrain. Virtually unchanged in design remains only a spoked wheel:... “ROTOR” WINNERS

“ROTOR” WINNERS

Model rotocut. In the championship of Russia for sport flying the first prize winners in the class of models of steel rotochutes Larisa Ivanova and Alexey dirt. Today, our material about...

The simplest collet was developed by the students in the CPC Leninsky district of the city of Alma-ATA. It can be used quickly and reliably to clamp cylindrical parts, shafts, axles, bushings. The fixture base is a steel flange, the flat end of which drilled four holes, through which the clip is bolted to the table of the drilling or milling machine. On a cylindrical surface of circular cross-section, and accordingly the same has a thread on the clamping lid. Inside the flange is a machined hole, its taper must match the taper of the standard collets. On the clamping lid is arm. A set of standard collets allows you to record in the fixture parts of various diameters. The application of the clip and the code of criminal procedure allowed to significantly reduce the time of drilling bushings and completely to eliminate defects — holes in the bushings are now positioned exactly on their axis.

The simplest collet was developed by the students in the CPC Leninsky district of the city of Alma-ATA. It can be used quickly and reliably to clamp cylindrical parts, shafts, axles, bushings. The fixture base is a steel flange, the flat end of which drilled four holes, through which the clip is bolted to the table of the drilling or milling machine. On a cylindrical surface of circular cross-section, and accordingly the same has a thread on the clamping lid. Inside the flange is a machined hole, its taper must match the taper of the standard collets. On the clamping lid is arm. A set of standard collets allows you to record in the fixture parts of various diameters. The application of the clip and the code of criminal procedure allowed to significantly reduce the time of drilling bushings and completely to eliminate defects — holes in the bushings are now positioned exactly on their axis.

The simplest collet was developed by the students in the CPC Leninsky district of the city of Alma-ATA. It can be used quickly and reliably to clamp cylindrical parts, shafts, axles, bushings. The fixture base is a steel flange, the flat end of which drilled four holes, through which the clip is bolted to the table of the drilling or milling machine. On a cylindrical surface of circular cross-section, and accordingly the same has a thread on the clamping lid. Inside the flange is a machined hole, its taper must match the taper of the standard collets. On the clamping lid is arm. A set of standard collets allows you to record in the fixture parts of various diameters. The application of the clip and the code of criminal procedure allowed to significantly reduce the time of drilling bushings and completely to eliminate defects — holes in the bushings are now positioned exactly on their axis.

The simplest collet was developed by the students in the CPC Leninsky district of the city of Alma-ATA. It can be used quickly and reliably to clamp cylindrical parts, shafts, axles, bushings. The fixture base is a steel flange, the flat end of which drilled four holes, through which the clip is bolted to the table of the drilling or milling machine. On a cylindrical surface of circular cross-section, and accordingly the same has a thread on the clamping lid. Inside the flange is a machined hole, its taper must match the taper of the standard collets. On the clamping lid is arm. A set of standard collets allows you to record in the fixture parts of various diameters. The application of the clip and the code of criminal procedure allowed to significantly reduce the time of drilling bushings and completely to eliminate defects — holes in the bushings are now positioned exactly on their axis.