Can we call today an industry where not carried to its good welding is a fast and reliable method of joining parts from different metals and alloys. Not accidentally, the interests of many young innovators are concentrated “around the electrode.” The army’s innovators N. Khvorostiv M. Bokov, S. Privateer built the unusual torch for arc welding in shielding gases. It is intended for the qualitative connection performance parts, made of steels and aluminum alloys.

Can we call today an industry where not carried to its good welding is a fast and reliable method of joining parts from different metals and alloys. Not accidentally, the interests of many young innovators are concentrated “around the electrode.” The army’s innovators N. Khvorostiv M. Bokov, S. Privateer built the unusual torch for arc welding in shielding gases. It is intended for the qualitative connection performance parts, made of steels and aluminum alloys.

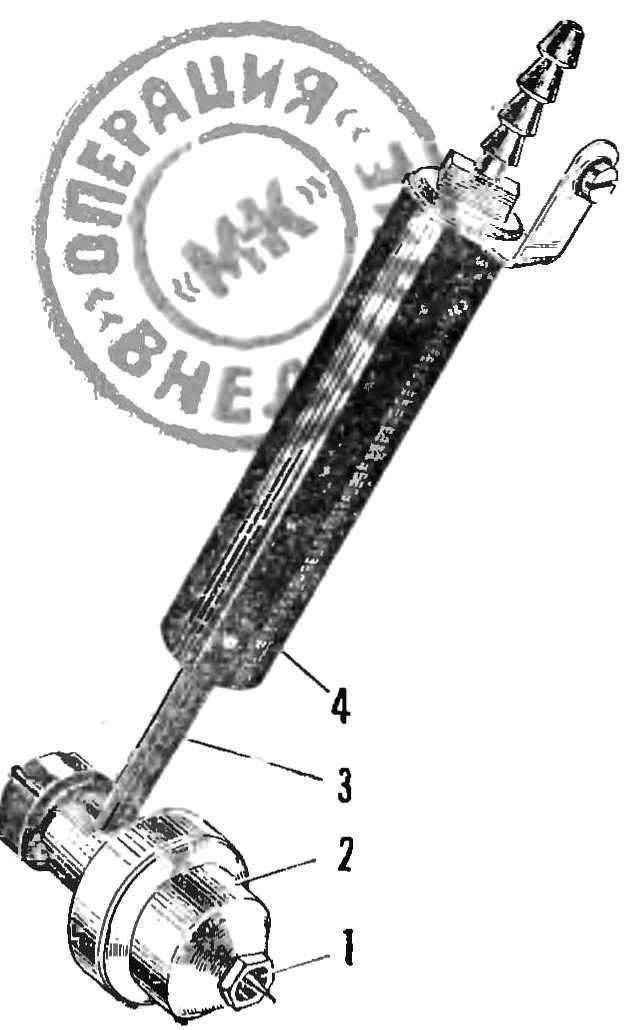

A distinctive feature of the burner is that it the nozzle device has a screw swirler. The shielding gas flow supplied to the welding zone, acquires a vortex motion in the nozzle, and the output from it. Due to this, around the tungsten electrode creates a dense cloud of gas protecting the molten portion of the metal from oxidation, and also increases the depth of metal penetration, increased arc stability, improved seam quality.

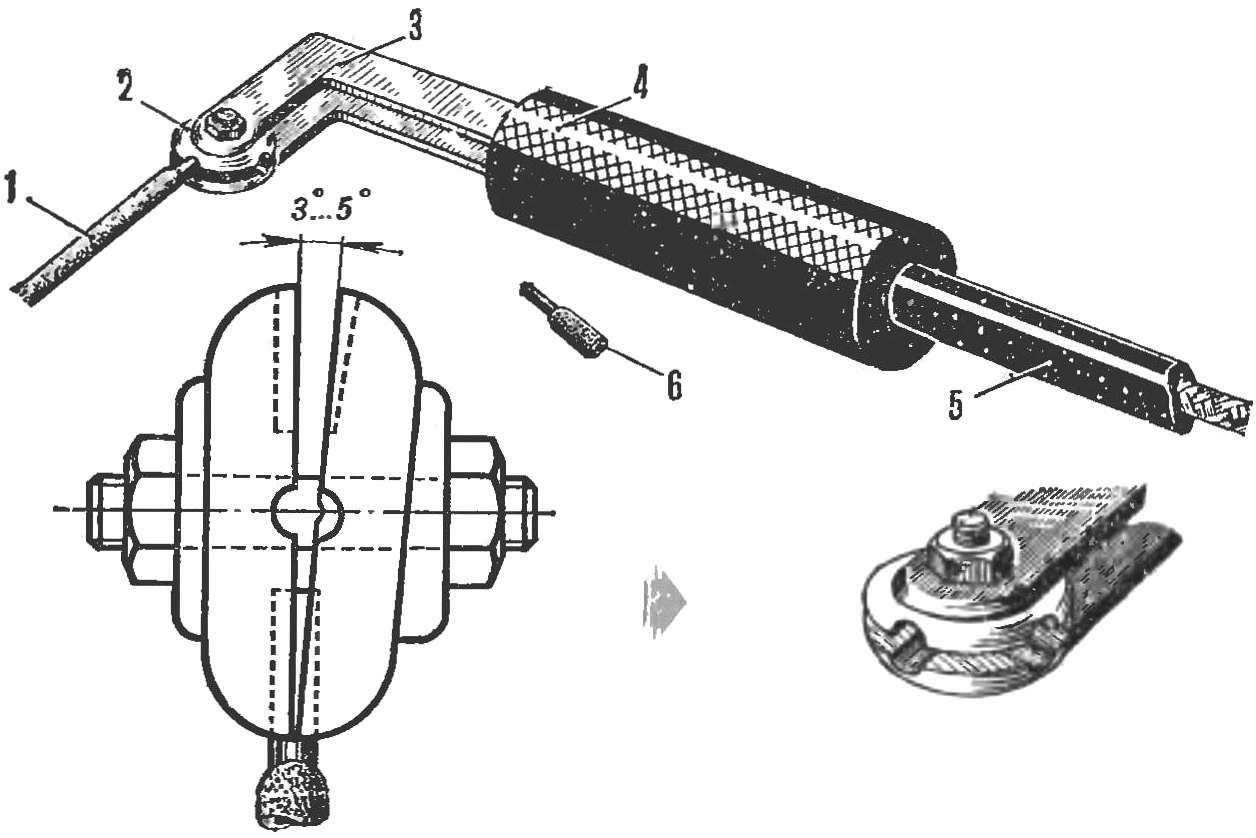

Another group of army of innovators — D. Amendment A. Glushko and E. Guillemot — designed the original electrode holder to work with metal electrodes. Its design completely eliminates the loss of time for deleting of cinder electrode.

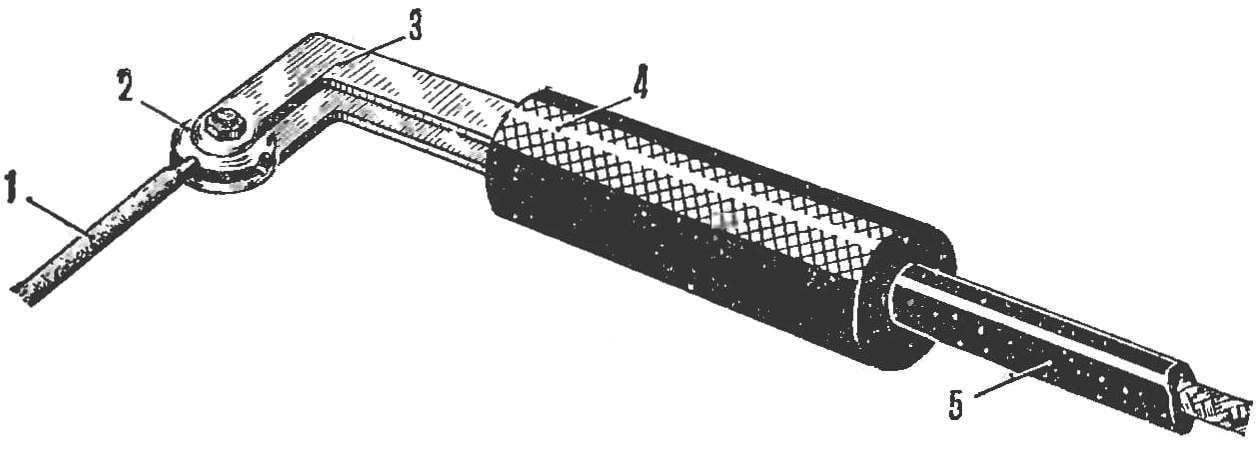

Welding head:

1 — tungsten electrode, 2 — vortex chamber with a screw, 3 — gazopodvodyaschey tube, 4 — pen.

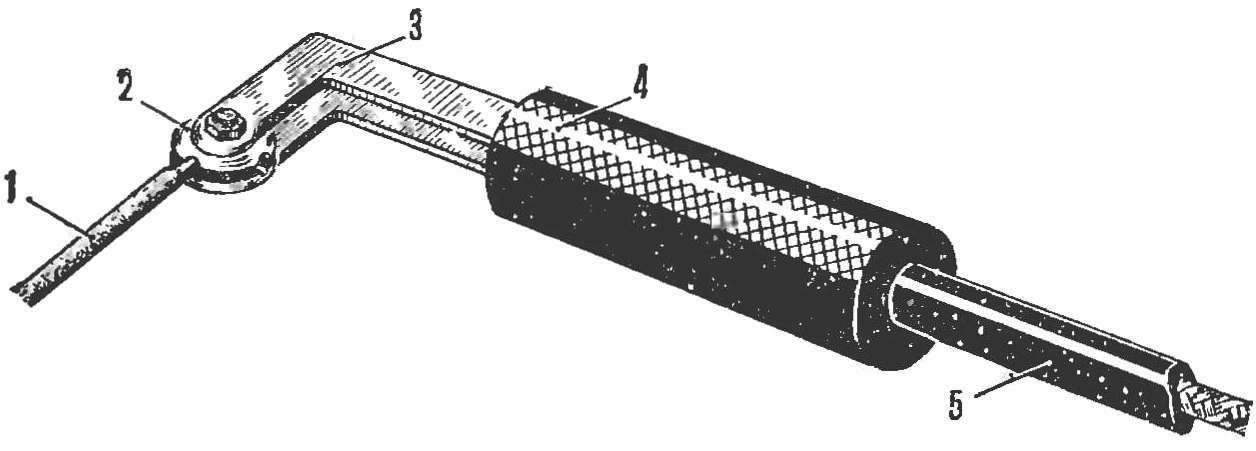

Automatic electrode holder:

1 — electrode, 2 — rollers, 3 — plate, 4 — handle, 5 — cable, 6 — piece electrode.

The holder consists of a housing-handle, two straps and sandwiched between two rollers, located on one axis at a small angle to each other. On the inner sides of the rollers are radial grooves-palmatoria. In the upper position they disagree, and as you scroll through the rollers when approaching the lower position converge more and more dense, forming a hole in which is clamped to the electrode. When he worked in the preceding hole to insert the new electrode, it is, as the lever, the rollers are rotated so that the electrode, being displaced in the lower position, clamped, and the calcine when the divergence of the rollers at the time of the turn automatically fall.

New electrode holder has a low weight, reliable in operation, improves productivity.