Not an easy job, manually to collect in the forest cones pine nuts. In addition, because the cones themselves, not the nuts. They need to be removed and this is done with the help of the machines installed at the collection points. However, the “output” of the nut of the bumps is small, so it turns out that for hundreds of miles to the collection point and deliver something that goes to waste.

Not an easy job, manually to collect in the forest cones pine nuts. In addition, because the cones themselves, not the nuts. They need to be removed and this is done with the help of the machines installed at the collection points. However, the “output” of the nut of the bumps is small, so it turns out that for hundreds of miles to the collection point and deliver something that goes to waste.

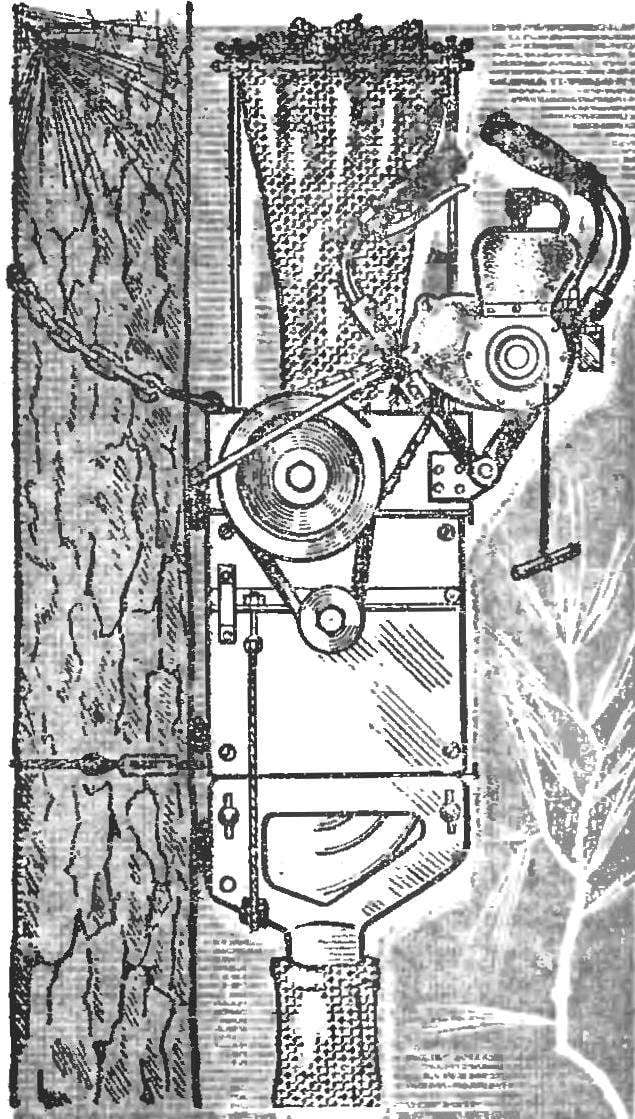

Enthusiasts of technical creativity in Novosibirsk’s Palace of pioneers set out to bring the process of cleaning the cones to the gathering place. This was designed and manufactured small-sized portable machine that fits in a normal backpack.

One after another appeared a few modifications to the cars, as the trials in the forest revealed some shortcomings in its design. The first was made in 1969. It was solved two main nodes: a crusher and a sieve. Cedar harvester worked for almost a full season, harvested about 20 bags of nuts, but worn bevel gear (made of St-3 without cementation).

The machine in the stowed state.

In the next version, created in 1971, the old model was only a crusher. But the added bottom sieve, fan; reinforced nodes that carry the main load. The machine has compact fixed when you work directly on the tree. In subsequent seasons the students were engaged in fine-tuning of individual parts. The harvester was successfully tested. Engine D-5 and main units worked perfectly. The spot was only the small stuff: broken fixing of the sieve to the drum, torn the cord of the vibrator, Unscrew some nuts.

Here is the description of the latest version.

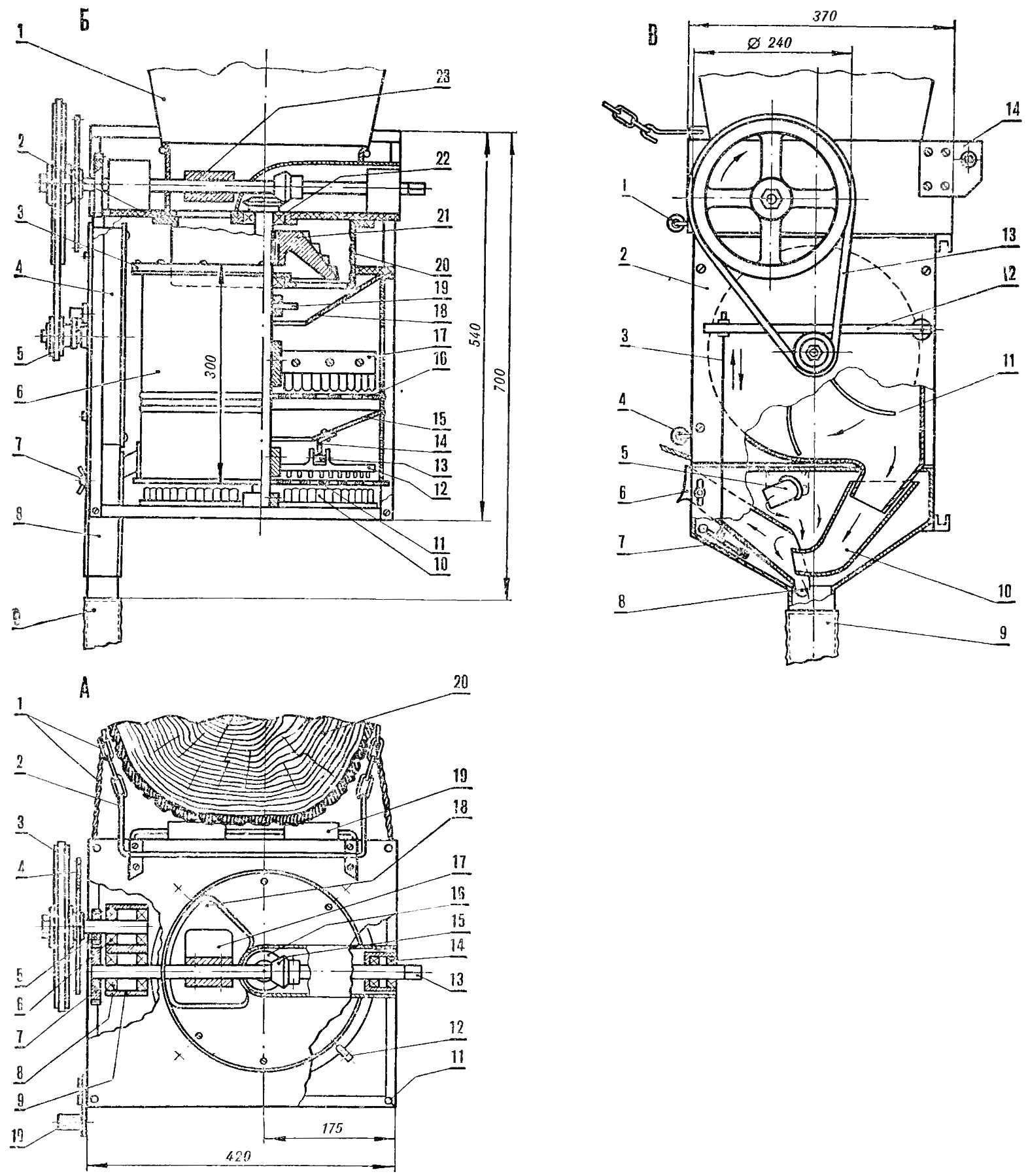

Device machine it is clear from the drawing and captions. A few words about the materials from which it is made. The drum is made of sheet of aluminum 1 mm thick mesh made of the same material 2— 2.5 mm. Frame is created from dural area 25X25 mm U-shaped profile glazing bead. Shaking is carried out by means of an annular hrasnica of steel 65G and a thickness of 2 mm. it is rolling steel roller Ø 12 mm mounted at the bottom scrapke.

The principle of operation. From the hopper is fed into the lump crusher is the rotor which has a cone shape with spikes with a height of 20 mm. For obsluzivanie bumps the wall crusher imparted an undulating surface. Fragmentation occurs smoothly, without the “Zakusov”.

Veselushka “mixture” is on the cone of the drum and falls on the center of the sieve. Since the drum vibrates with a frequency of 12 oscillation per revolution of the rotor, the nut instantly goes down and falls through the sieve. Large husk scrapers pushed to the walls of the drum. Scrapers are curved in the form of bucey S. Through the side window of the husk thrown out. The window is elongated and has a “threshold”, the height of which is regulated by the damper. This improves the brushing and prevents the release nut.

Walnut and fine chaff, having a first sieve, a vortex going in the center of the second. It is replaceable, has a rectangular hole size mm 5X12 6X15 or (depending on the size of a walnut). The average width on one side of the wire, with the other rubber brush.

Everything that can go into holes, falling down under the machine. Walnut also scrapers are discarded to the walls of the drum. The lower brush is mainly used for cleaning the holes on the stuck husk and a small nut.

“Mixture” emitted from the mouth, enters the node, final cleaning, where under the action of a striker-vibrator (1200-1500 cycles per minute) it is, in fact, is always in the air. The flow from the fan otviewit soft body and carries them, a nut, with greater weight, goes downhill through the sleeve in the container. The site is based on “clean” release of the nut, so there is the possibility of adjusting: the tilt of the whole mechanism, changes the position of the flap in the path of the air stream from the fan, the engine speed (increased speed increases the yield of pure nut into the collecting hopper cars). The engine works steadily as on small, and at high speeds.

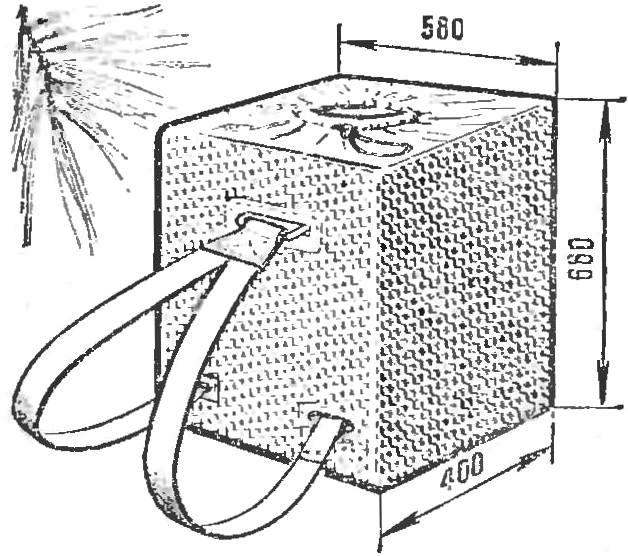

Diagram of the machine:

A — top view (without hopper): 1 — chain p rope fastening; 2 top bracket; 3 — drive pulley of the fan; 4 — driven sprocket (Bicycle); 5-pinion Z-20; 6 — the bearing 203; 7 — gear Z-60; 8 — the bearing № 204, 9 — bearing housing; 10 — a bracket of fastening of the engine; 11 — socket rack-cross bars hopper; 12 — latch of the neck of the hopper; 13 — shaft; 14 — the bearing № 205; 15 pinion Z-20; 16 — gear Z-16; 17 — blade-grip (rubber); 18 — input window in the mill; 19 — shock absorber (rubber); 20 — the trunk of the tree.

B — front: 1 — hopper; 2 — upper panel (PCB); 3 — flange (rubber); 4 — casing; 5 — driven fan pulley; 6 — drum; 7 — a nut-lamb; 8 — console final processing; 9 — sleeve; 10 — the lower scraper; 11 — final cleaning sieve (hole size 6X12 mm); 12 — blade secondary scraper; 13 — roller vibrator; 14 — cylindrical ratchet; 15, 18 — a cone-funnel; 16 sieve (hole Ø 12 mm); 17 — upper scraper blade; 19 — mixer; 20 — drum crusher; 21 — rotor crusher; 22 — the bearing; 23 — bushing blade-grip.

In the left view: 1, 4 — shock absorber (rubber); 2 — fan; 3 — wire Ø 3 mm; 5 — exit tube nut; 6 — console winnow; 7 — drummer-vibrator; 8 — axis kachana winnowing; 9 — sleeve; 10 — nozzle; 11 fan; 12 — yoke; 13 — fan belt; 14 — bracket engine mounts.

To prepare the machine for operation and to clean best together. Lifting it to the desired height, first fix the upper part of the chain, and then lock — bottom. The machine does not have sharp edges to touch the tree trunk. Height depends on growth and terrain, and given the fact that about cars quickly accumulates chaff, which periodically must be removed.

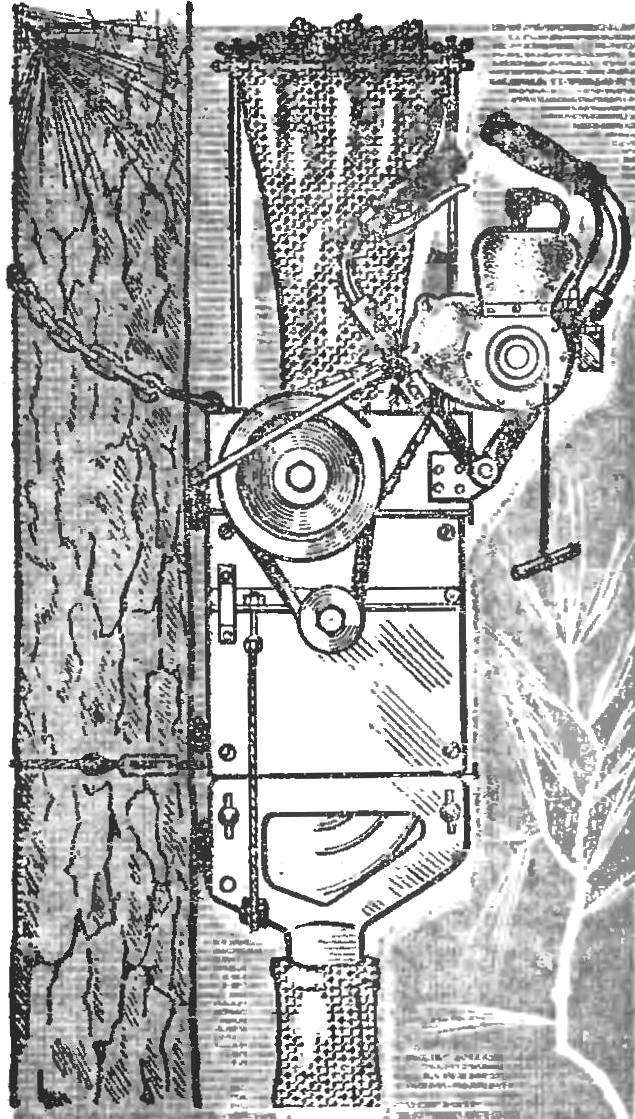

In the stowed position the machine is in a canvas case with a plywood bottom. Shoulder strap thread-through case.

The kit cars includes sieves for drying walnut: three metal size 450X400X80 mm and two wooden size 620X330X60 mm. All of this also fits into the case.

Engine D-5 (fan forced cooling), the tank, stretching and tool are placed in a separate bag and weigh 10-11 lbs.

TECHNICAL CHARACTERISTICS

Dimensions of machine (in case), mm…….680Х580Х400

Weight (without motor), kg…………………….20

The speed of rotation, Rev/min:

drive shaft……………………………..60-80

crusher’s rotor…………………………….70-100

fan…………………………………..1500-2000

Feed cones………………………………..automatic

Engine……………………………………….D-5 with forced cooling

Fuel…………………………………………gasoline A72 (with oil)

Fuel consumption, l/h ………………………..0,4

Arnosti, %……………………………………0,5

The release nut with the husk, %…………….0,5

V. ROGOZHIN, Novosibirsk, Russia