to Build a simple ship models — hobby many guys. With the onset of warm days on the water bodies appear whole flotilla of tiny boats, catamarans, yachts, rafts. But the trouble is that many of them can “walk” independently. Want an easy economical engine.

to Build a simple ship models — hobby many guys. With the onset of warm days on the water bodies appear whole flotilla of tiny boats, catamarans, yachts, rafts. But the trouble is that many of them can “walk” independently. Want an easy economical engine.

The case will help microelectronical DP-12-A (DP-4, MP-2P, “Normal”) running from the battery 3336L. It’s the “revive” your model.

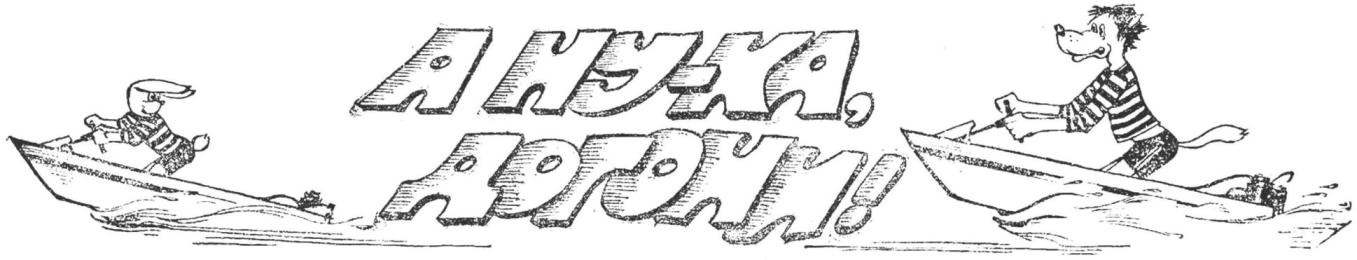

Microelectronical fixed casing PA stern tube, through a flexible transmission transmits the rotational force of a propeller (Fig. 1).

Billet casing cut out from sheet tin or brass with a thickness of 1 mm and connect into a ring by inserting the tongue in the corresponding slot (Fig. 2). The resulting ring shape of the housing of the motor, at the same time objav stern tube (see Fig. 4).

If you decide to use a motor of another type, make a new template out of paper and make it a billet cover.

Using Acme ledge to the ribs, but the edges of the engine is attached by a screw to the stern of the ship. The location of the motor model specifies the direction of motion.

Fig. 1. The appearance of a outboard motor.

Fig. 2. Casing.

Fig. 3. The template for the propeller.

Fig. 4. Outboard motor Assembly:

1 — microelectronical, 2 — casing, 3 — transmission, 4 — propeller shaft, 5 — washer, 6 — propeller 7 — deadwood.

Fig. 5. The test boat

Deadwood — cut metal tube O 6 mm, length 75 mm with a wall thickness of about 0.4 mm. In its lower part of drill hole O 4 mm bearing for the propeller shaft — a piece of plastic or metal tube. It is glued or soldered.

The propeller is also cut from sheet tin or brass template (Fig. 3) and drill the center hole depending on the diameter of the propeller shaft. The latter is made of a steel rivet O 2.5 mm and length 12 mm. the Propeller shaft rotates freely in the bearing with a minimum of longitudinal oscillations. Regulate it, changing the depth of the nozzle fluid tube.

The propeller is soldered (or glued) to the head of the shaft. On both sides put it on but the washer tin or Micarta, which excludes inhibition between the fixed and rotating parts.

The blades should be rotated through an angle of 30° relative to the plane of rotation.

The transmission is a segment of a rubber tube (from valve Bicycle inner tube) with a length of about 45 mm. One end fitted on a shaft of the electric motor and the other row (Fig. 4).

Instead of rubber tubes can be applied spring O 2 mm. With the two shafts it connects back to back with the help of segments (6-8 mm) polyethylene tube.

Loop Transmission should be smooth, with no sharp bends. Adjust it by moving the deadwood up and down or turning it.

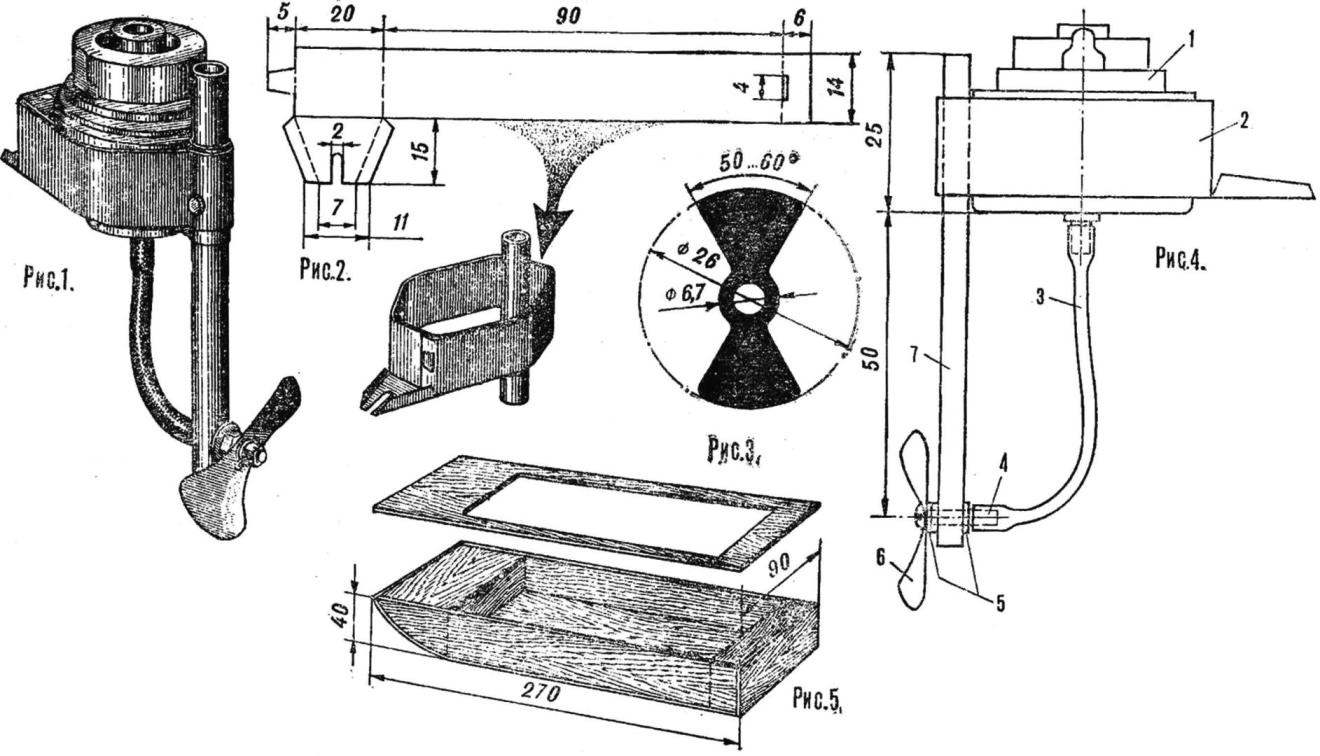

It remains to check the finished engine in. But if you don’t have a suitable model, make a simple small boat, consisting of seven parts (Fig. 5). The sides and transom model cut out from thin plates, and the bottom is cut out of rigid cardboard. Bow and stern pillars made of wood or solid foam, plywood deck has a large open hatch.

Collect the vessel using small nails and waterproof glue.

A model impregnated with hot linseed oil and then painted. When it dries, set on the stern outboard motor, and the housing is a battery 3336L.

Now you can go sailing.