In various sectors of the economy are in the service of conveyors with rubber-fabric belts by moving a variety of materials, details. Therefore, the wide application can find quite a simple device for the preparation of such tapes to the dock, introduced ka production Association “Karatau”.

In various sectors of the economy are in the service of conveyors with rubber-fabric belts by moving a variety of materials, details. Therefore, the wide application can find quite a simple device for the preparation of such tapes to the dock, introduced ka production Association “Karatau”.

The device attaches to the stepped form of the ends of the conveyor of the ceiling, which are connected by vulcanization or chemical welding. The result is a joint that is almost equal to the strength and durability of the tape itself.

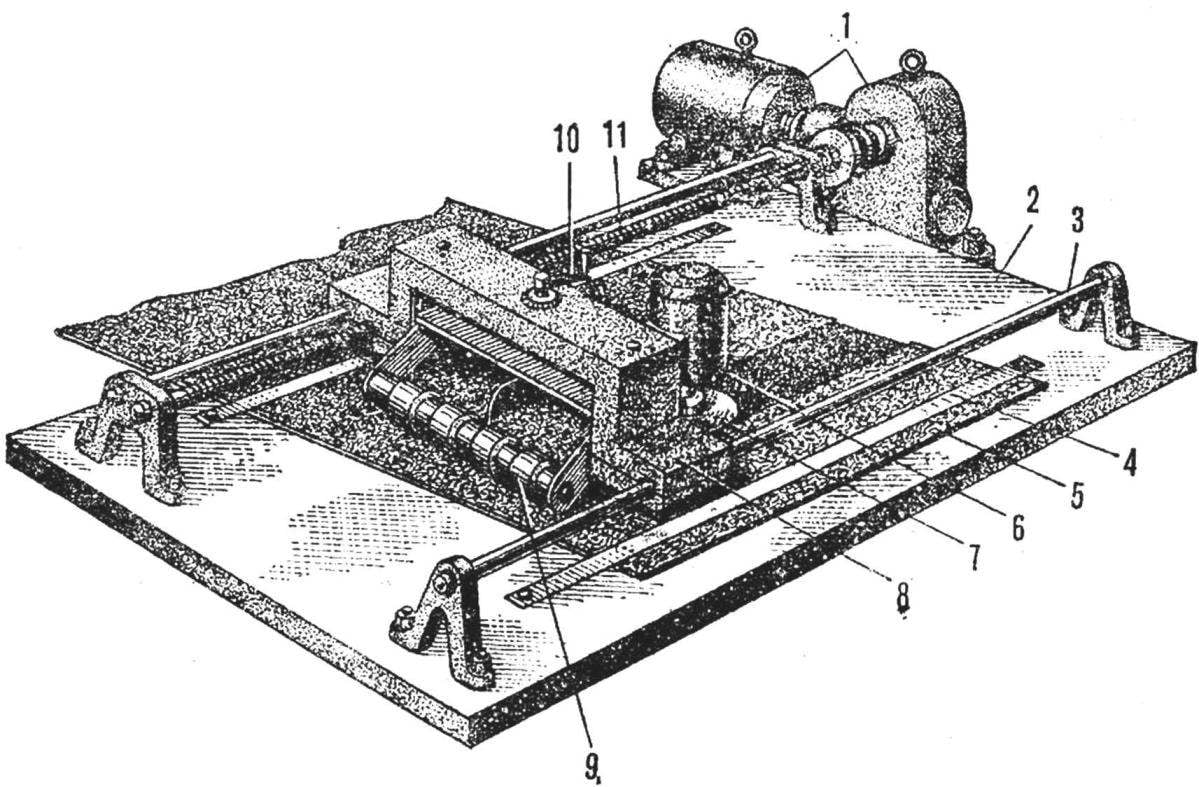

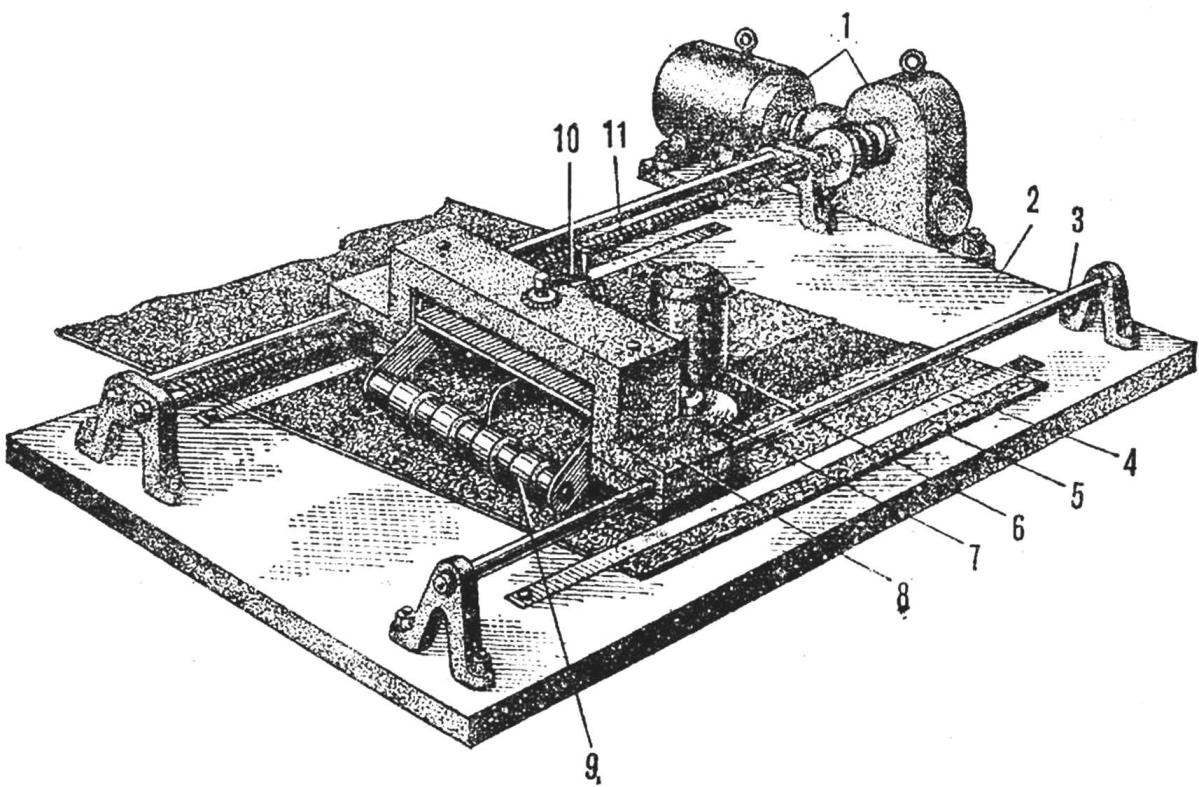

Butt-machine:

1 — electric drive with reduction gear, 2 — table, 3 — rail, 4 — bar rake, 5 — belt 6 — motor carriage, 7 — disc knife, 8 knife — carriage, 9 — pressure rollers with vertical knives, 10 — adjusting screw with a handle, 11 — screw.

The fixture consists of a horizontal table along which the brackets fixed guide of the knife carriage. Its movement provides the electric motor torque through the gearbox spindle, mounted along one of the rails. On the carriage is placed a second engine to drive the knives: they are on the carriage several. The main, circular knife is used to slice a horizontal layer of tape. At the same time it has a number of vertical blades, located between the clamping rollers.

The tape is laid on the table of the fixture and fixed rails with hinged bolts. The inclusion of a reversible electric drive carriage is brought to the edge of the tape, and rotate the adjustment screw with a handle to set the desired depth of the horizontal cut with a knife. Then included both engines, implemented the first working passage of the knives on the canvas. The number of passes, and therefore, the docking of stages depends on the number of layers of tape.

The device minimizes the use of manual labor, greatly improves the quality of the preparation of the joint, provides significant material savings, reduces the time spent ka all activity on the connection tape.