Making wardrobe-hanger in the hallway, I proceeded from the features layout of the apartment is an old building. I have, in particular, opposite the entrance is the door to the closet, so the rack has lateral bevels, which allows him to open the door.

The size of this in relation to my apartment. The trim for the doors of the compartments used plastic. Rack and harness rack coat hanger is made from ash, coated with hot linseed oil (or furniture Polish). Side panel and a mezzanine, the upper and lower panels mezzanine is made of plywood, also impregnated with hot linseed oil. It should be borne in mind that the lower panel on the mezzanine is simultaneously the “roof” of the compartment for casual wear, so the plywood as possible it is necessary to pick with a beautiful texture, as it is easily visible from below.

All joints of the frame by casein glue in the spike. Rack and rail rack have longitudinal grooves into which are inserted during Assembly of the side and rear panels of the Cabinet. The grooves are selected on a homemade machine of the type “Skillful hands” circular saw in two passes.

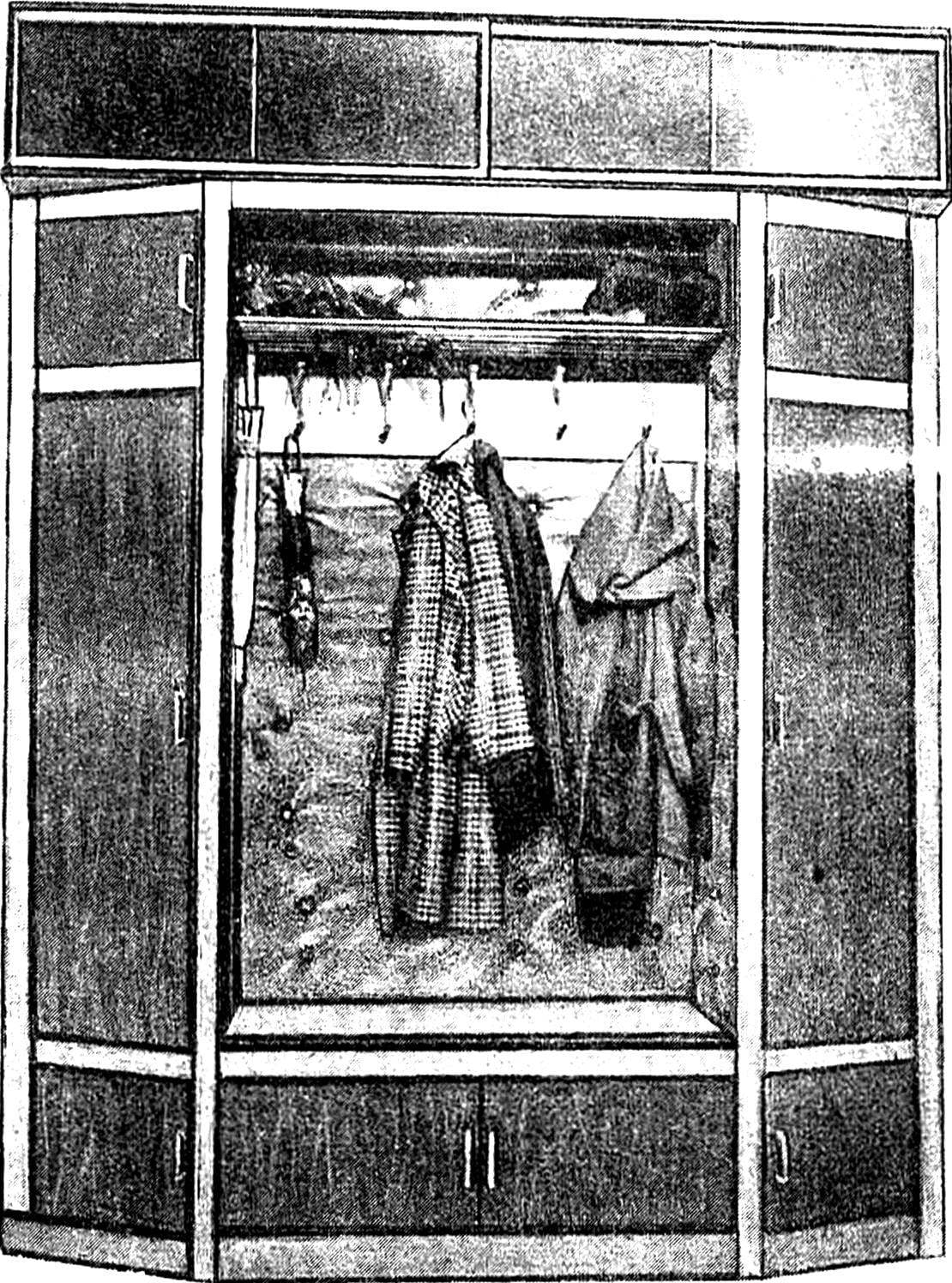

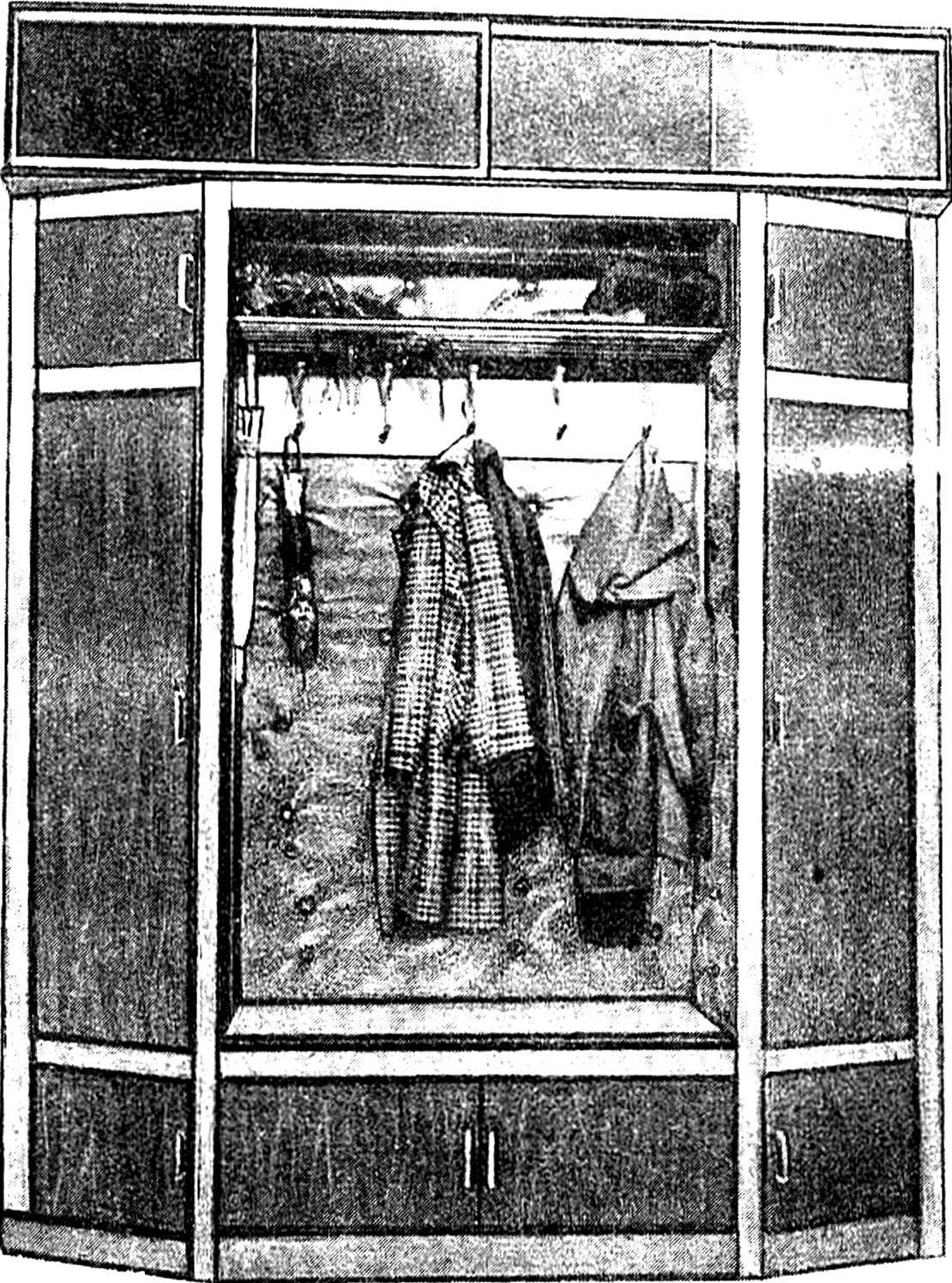

Clothes rack:

1 — suspension frame 2 — door compartments for shoes, the 3 — door handles 4 — door compartments for seasonal clothes, 5 — doors, clothes compartments, 6 — side panel (plywood with a thickness of 3-4 mm), 7 upholstery nails, 8 — hooks for casual wear, 9 — mezzanine section 10 — sliding glass, 11 — shelf for hats (brass tube Ø 15 mm), 12 — Board hooks for clothing, 13 — soft padding write for casual wear, the 14 — rear wall of the Cabinet, 15 — stiffener rear wall, 16 — sleeve 17 — baffle, 18 — stiffening bulkhead, 19 — bolt M6.

Door compartments are assembled from thin strips in casein glue with fixing small nails; both sides they are pasted over with plywood and plastic. Door sizes choose slightly larger than respective apertures, and only after final Assembly is an exact fit. When facing the adhesive foam pad on the surface of the plastic and plywood with a thin layer; then superimposed on top of the plastic material is applied to the paper in several layers and a thick sheet of plywood. Thus, the package is evenly crimped clamps and kept under pressure during the day. When tightening the clamps it is necessary to ensure that the plastic is not moved from the door surface as the adhesive forms a kind of lubricant, and a sheet of plastic can move out. For this reason, it should provide about an inch more the size of a door. Each door is mounted on two makeshift sheds made from steel plates of 3 mm thickness and covered with black nitro.

Shelves in compartments and bottom Cabinet is made of plywood with thickness of 7-10 mm, attached with steel corners. Strap hooks for clothing from well-planed ash boards; attached the design to the spike on the glue in the Assembly process. Side and rear compartment panels casual clothing is made of plywood thickness of 4 mm; when the Assembly is inserted into the grooves of the posts and studs of the closet. From the back side they have the ribs; the distance between them is chosen with the expectation that they subsequently will be hammered furniture nails fastening soft upholstery.

Upholstery is manufactured in the following way. Plywood 4 mm thick machined billet size is slightly less than the openings of the compartment (based on the bend of the skin). They glued a sheet of foam with a thickness of 10-20 mm.

Frame:

1 — the ground Board, 2 stands (timber 50X50 mm), 3 — Board strapping section 24X50 mm, 4 — Board for clothing hooks section 25X160 mm.

Mezzanine section:

1 — vertical panels, 2 — wooden peg, 3 — angles, 4 horizontal panels, 5 — guides for sliding Windows, 6 sliding glass.

The door hinges.

The attachment of shelves.

You can use foam pads or thick foam carefully cut into bars. A small difference in thickness is not terrible, as covering their skin hides irregularities. On top of the glued foam rubber coating stretched faux leather or leatherette, tucks and podklyuchaetsya adhesive No. 88 on the back side of the sheet of plywood. The stretch should be smooth, without wrinkles and folds. Soft finished furniture panels are attached with nails. Decorative nails can be made independently. Covered with leather, they also decorate the place. The basis of the cap will serve as brass or copper washers with a diameter of 20-25 mm. Hammer with a round striker it is necessary to give them a slightly convex form (better to use a matrix and a punch). In the center of the drilled hole of the cap; a core hole is attached to the taper, there is inserted an ordinary nail and sealed. As a flux is used soldering acid. Leather cut in a circle, the diameter is somewhat larger than the nail head. Edge of the circle is cut with an asterisk. Adhesive No. 88 is applied to both surfaces of the glued parts, aged for 15 minutes, after which the circle is superimposed on the hat and carefully circles her tongue “stars”. So as not to damage the nails, they should not drive, and push in the planned awl holes of the panels.

Shelf for hats represent six brass tube 15 mm in diameter. they are Mounted with screws, screw in bushings. The internal depth of the bushings has a stock. With tight sleeves (to lock) the width of the tubes is smaller than the aperture of the compartment that allows them to freely insert into the opening. While tightening the bolts the bushings are shifted to the panels than provide a clear fixation of the tubes. To pipes are not oxidized, it is desirable to cover with an oil varnish.

Housing the mezzanine consists of three vertical and two horizontal panels that are connected on a plug-in round thorns (nails) with the strengthening from the inside metal parts. The back wall (made of plywood 4 mm thick) nailed. For fixing mezzanine on the Cabinet used stainless steel parts. From the front “mezzanine closed the four doors of a 4 mm glass coated on the inner side of the black enamel. Glass move along the guide rails out of ash slats with the grooves, and the depth of the grooves in the top rails is greater than the lower, so that, lifting the glass, it could be drawn out of the frame. Panel mezzanine glued together from several sheets of plywood to a thickness of 18-20 mm casein glue, using clamps. The ends of the panels can be covered with putty based on epoxy resin, adding to the already diluted to a density of the test resin talc and black artist oil paint (from a tube). Not to dirty the front panels, they must be closed with adhesive tape.

The layout of the hall:

1 — door, 2 — self-made wardrobe, 3 — door pantry.

Technological operations:

And — receiving grooves under plywood panels and sliding glass;

B — gluing doors:

1 — rail frame door cross section 15X40 mm 2 — facing the plastic 3 — plywood panel doors, 4 — auxiliary plywood sheets, 5 — clamp, 6 — paper strip.

V. VESELOV, Kholmsk, Sakhalin region.

Recommend to read BACK TO THE JIGSAW… This device allows you to consistently perform those operations which are performed simultaneously jigsaws, tension and clamp the blade. It is especially difficult to learn this kids —... AND THE OLD DRIVE IN THE CASE The old wheels of trucks can be used as the columnar foundations for light timber frame buildings — garden sheds, sheds green. Enough after installation and leveling to fill the disk... Scroll back to top

Making wardrobe-hanger in the hallway, I proceeded from the features layout of the apartment is an old building. I have, in particular, opposite the entrance is the door to the closet, so the rack has lateral bevels, which allows him to open the door.

Making wardrobe-hanger in the hallway, I proceeded from the features layout of the apartment is an old building. I have, in particular, opposite the entrance is the door to the closet, so the rack has lateral bevels, which allows him to open the door.