From circular knives, no matter where they worked in agricultural units, in the fields or in industrial plants, — wear out really fast sharp working edge. Therefore, innovators tend to find the most effective method of restoring the load of the tool.

From circular knives, no matter where they worked in agricultural units, in the fields or in industrial plants, — wear out really fast sharp working edge. Therefore, innovators tend to find the most effective method of restoring the load of the tool.

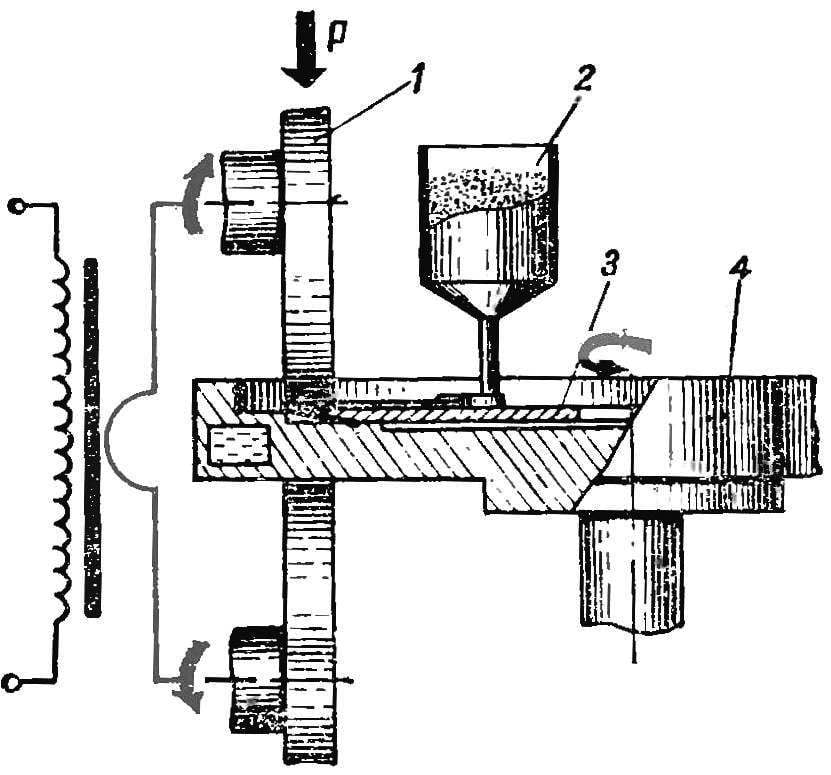

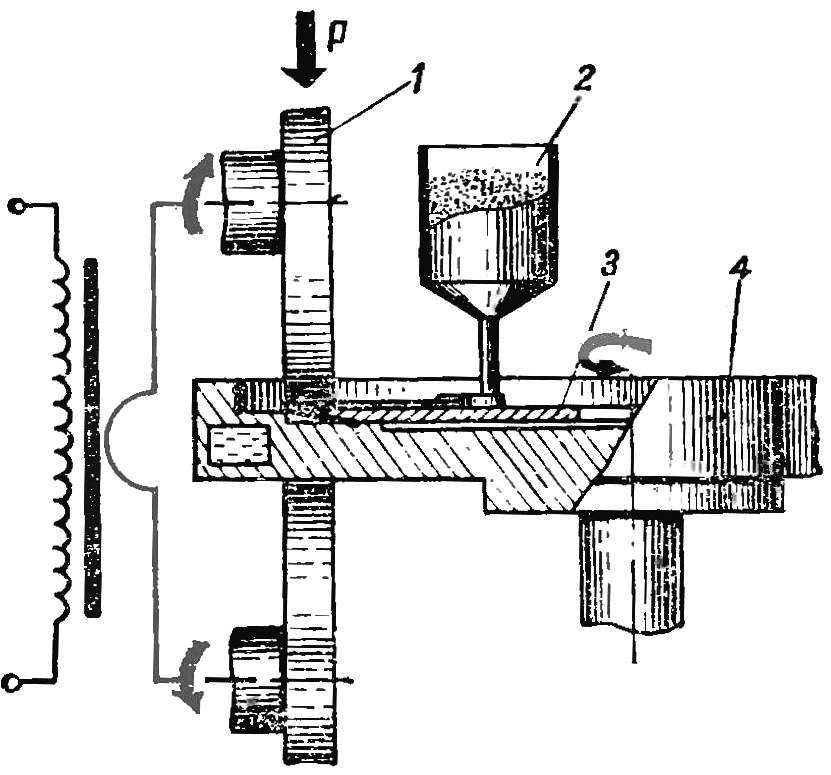

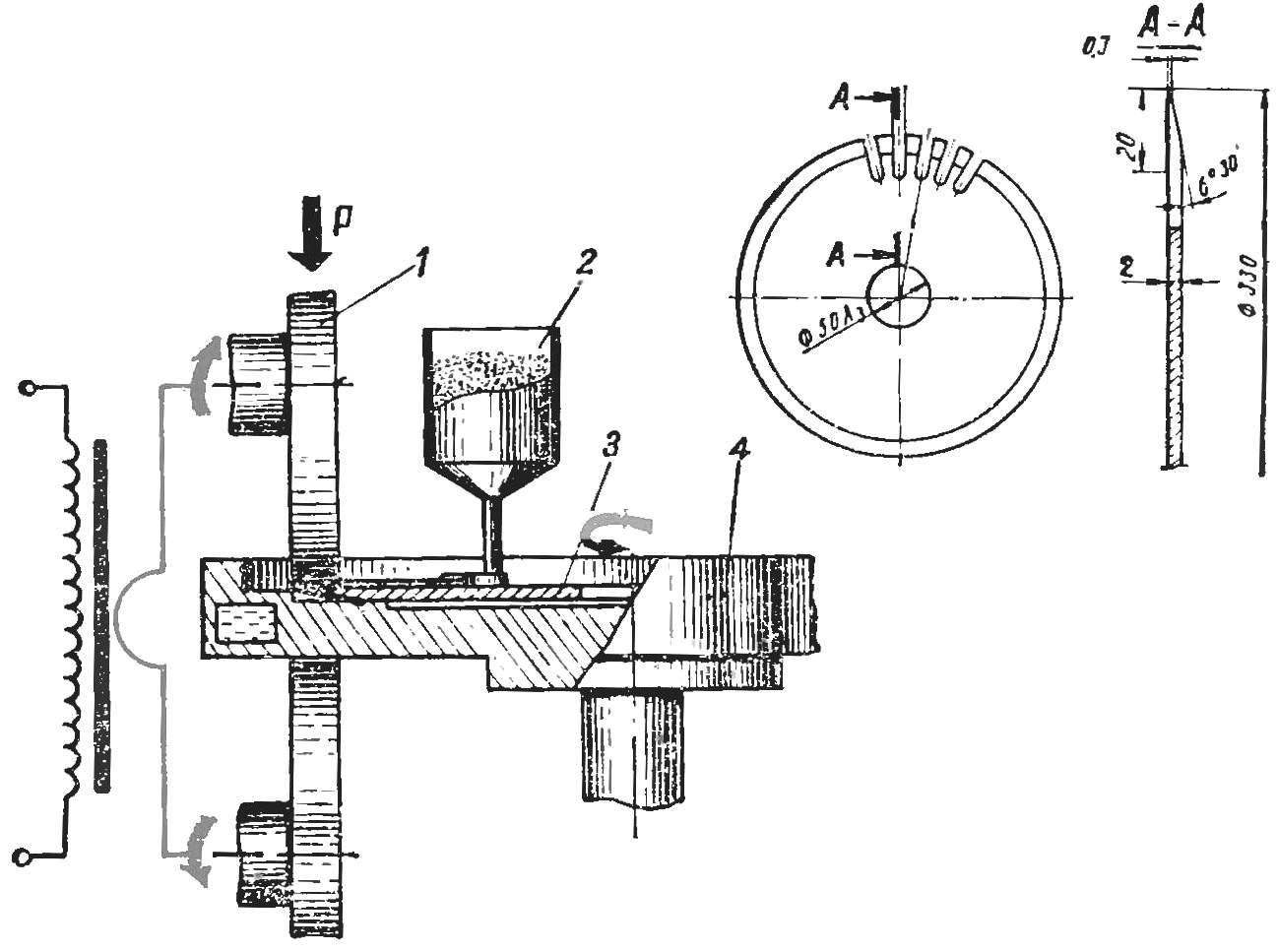

Innovators of the Mogilev plant “Strommashina” named after the 50th anniversary of the Great October revolution have implemented in the enterprise simple installation for electrocontact welding of the circular knives of the machines that are mechanized stone pine for the production of wavy slate sheets. For these purposes was used the contact suture machine MSH-3201. Between the roller electrodes located water-cooled copper faceplate, in which is placed the restored disk knife. On the surface from the hopper is fed filler material powder brand PG-ХН80СП.

Disc knife (top) and fixture for surfacing:

1 — roller electrode, 2 — bunker, 3 — disc knife, 4 — faceplate.

Upon rotation of the faceplate with the drive roller electrodes tested in its working edge, naplavlena new sing up to a thickness of 0.4 mm and a width of 20 mm.

Electrocontact method infusible powder materials allows to increase the service life of the blades in 8— 10 times. The annual economic effect from implementation of the unit is 100 thousand rubles.