Probably there is no sector of the economy, which would not have developed or used bulk materials. And for most of these powdered products is the most insidious enemy — humidity. To get rid of her, used a variety of dryers, which despite their structural dissimilarity is used most often one and the same principle of dehydration — contact: the powder comes into contact with the hot surface inside the evaporation chamber of the installation. However, such contact is harmful to many materials because of the high temperatures they lose their quality.

Probably there is no sector of the economy, which would not have developed or used bulk materials. And for most of these powdered products is the most insidious enemy — humidity. To get rid of her, used a variety of dryers, which despite their structural dissimilarity is used most often one and the same principle of dehydration — contact: the powder comes into contact with the hot surface inside the evaporation chamber of the installation. However, such contact is harmful to many materials because of the high temperatures they lose their quality.

This shortage is not a new drying device developed by Cherkassky innovators. They created the installation, is simple in design and effective in operation, based on advanced technological principle — drying in a suspended layer. The essence of the process will become clear if we remember the old circus act. The magician pretends that he wants a thin wand to pierce bottom small ball and he suddenly rises up and hangs over her, supported by an unknown magical force. The trick is that it hovers over… the tube from which comes a stream of air.

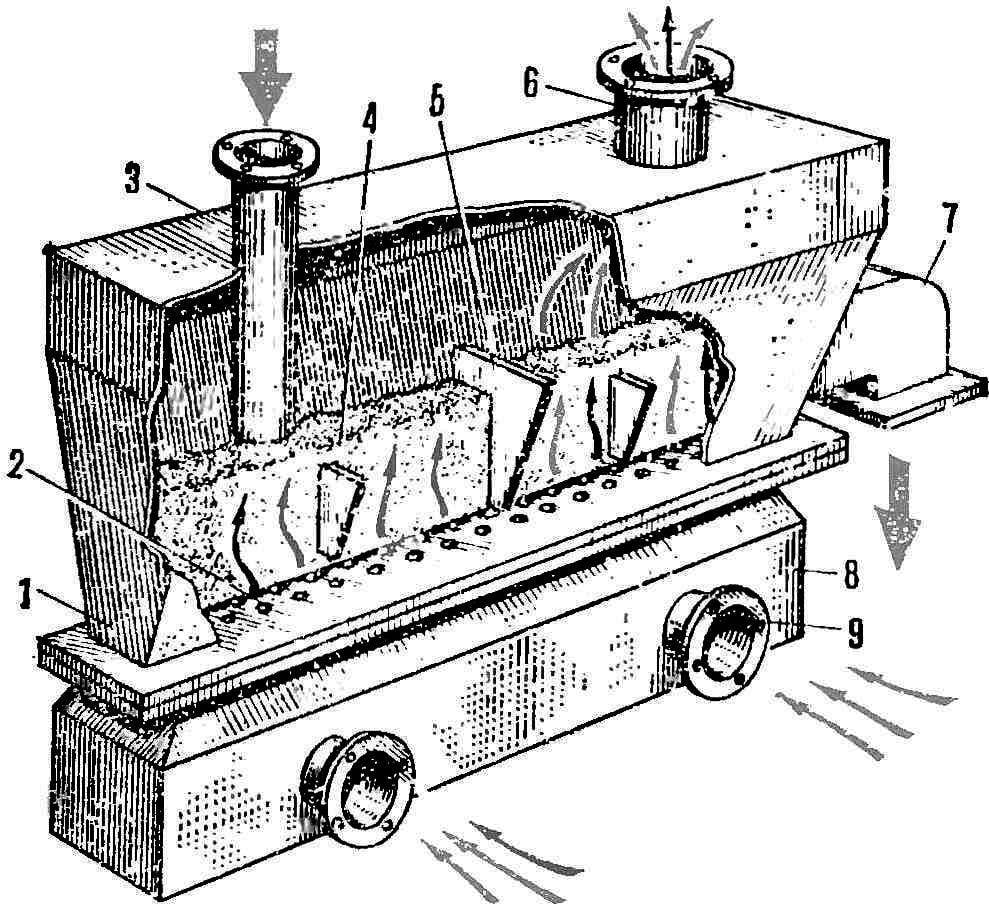

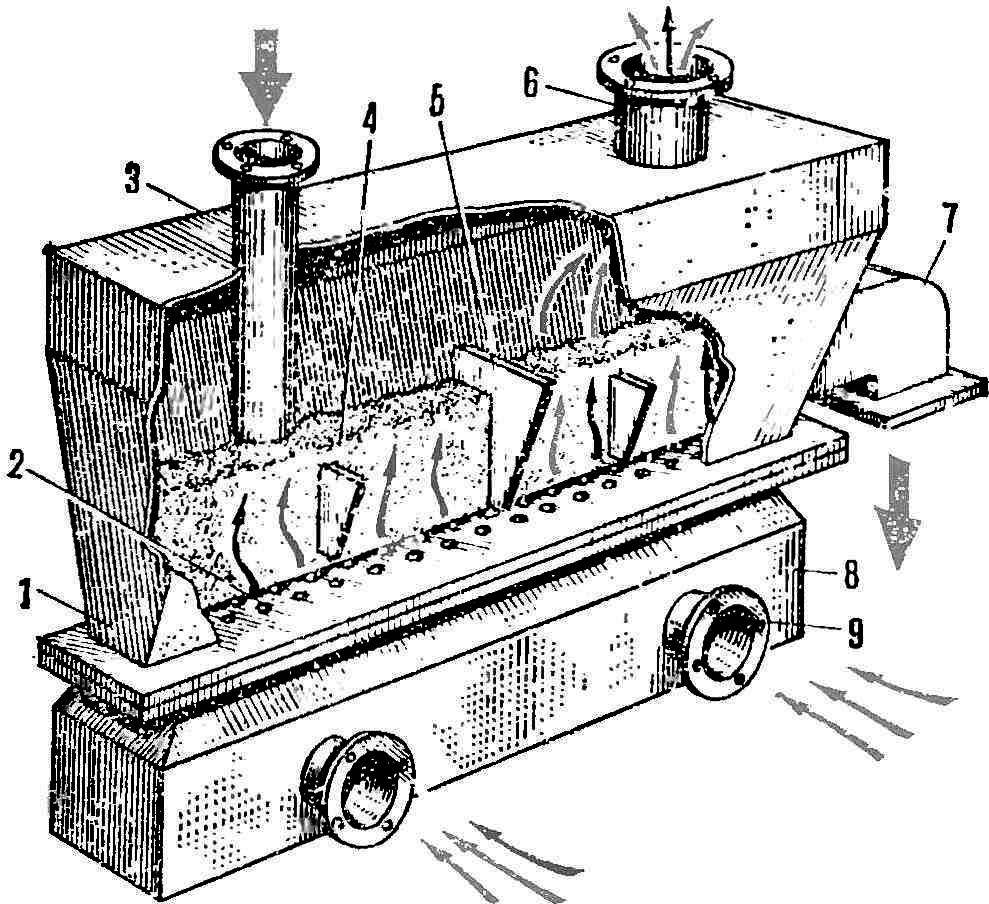

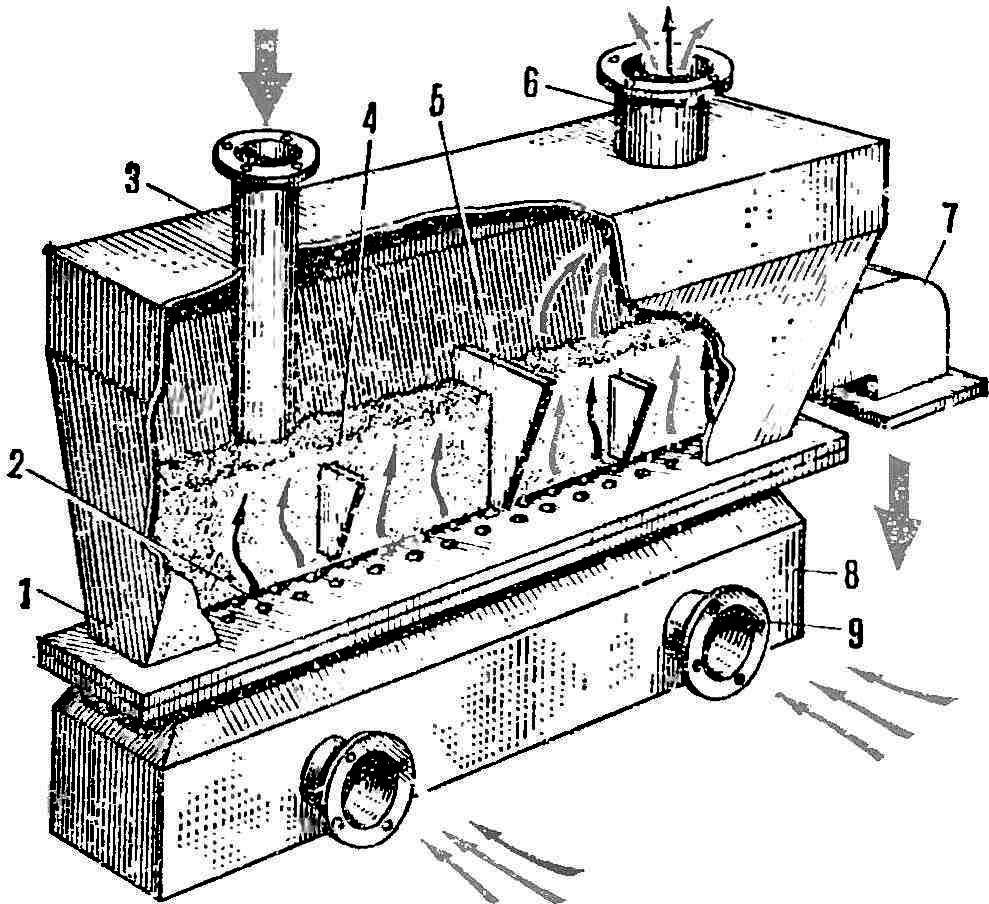

Of this kind of tube is and the bottom of the drying chamber of the apparatus is a gas distribution grid. Through from receivername box is served heat carrier heated to 110° air. On his jets and freezes, like many bulbs, dried powder. Supplied through the sleeve of the loading device of raw material like boiling in a stream of hot air, quickly losing moisture and gradually shifting to the discharge manhole. Installed across the movement of the regulating walls and the separation wall contribute to obtaining uniform dried substance.

Fig. 5. Apparatus for a balanced drying:

1 — drying chamber, 2 — gas distribution grid, 3 — boot sleeve, 4 — bulkhead, 5 — dividing wall, 6 — output window exhaust air, 7 — hatch for unloading the dried product, 8 — resivery box coolant 9 — the input window for the heated air.

The strength of the jet of hot air is regulated so that the speed of each air fountain exceeded the critical rate of descent of the largest fractions of the product, eliminating the possibility of contact with a heated gas distribution grid and achieves high-quality dehydrated products regardless of their initial moisture content.

Sectionist drying chambers created by the partitions, the machine gives it an additional advantage: within each section you can give the coolant another, increased or decreased temperature; a heat pipeline further enhances the quality of drying of bulk materials.