It would seem that not so long ago appeared in our kitchens “blue light” — the first of the Saratov gas. The enthusiasm that accompanied the displacement of them wood-burning stoves, kerosene stoves and kerosene stoves, over time, subsided. Gas was not an ideal fuel for stoves. The allocation during the combustion of harmful substances, the constant danger — and suddenly blow out the flames the wind and the room is filled with explosive mixture, — all this has led to the fact that gas stoves were gradually superseded by electric. The advantages of the latter compensate for even that heat the burner costs a bit more expensive.

It would seem that not so long ago appeared in our kitchens “blue light” — the first of the Saratov gas. The enthusiasm that accompanied the displacement of them wood-burning stoves, kerosene stoves and kerosene stoves, over time, subsided. Gas was not an ideal fuel for stoves. The allocation during the combustion of harmful substances, the constant danger — and suddenly blow out the flames the wind and the room is filled with explosive mixture, — all this has led to the fact that gas stoves were gradually superseded by electric. The advantages of the latter compensate for even that heat the burner costs a bit more expensive.

And I think that to take a gas stove to the scrap still early. You only need to get rid of some of the shortcomings. And it is quite possible. Converted from a conventional, gas operated stove in my kitchen for over two years and security does not differ from electric.

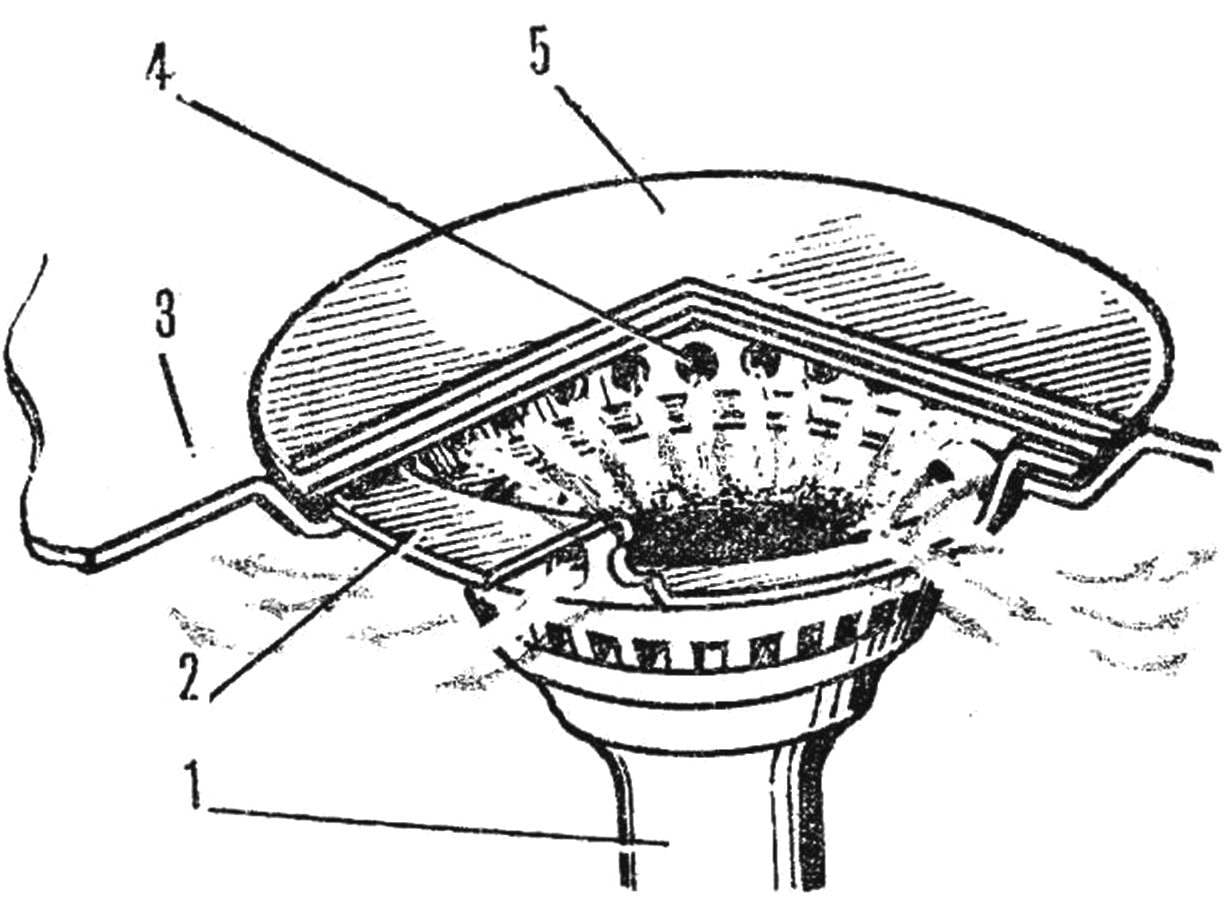

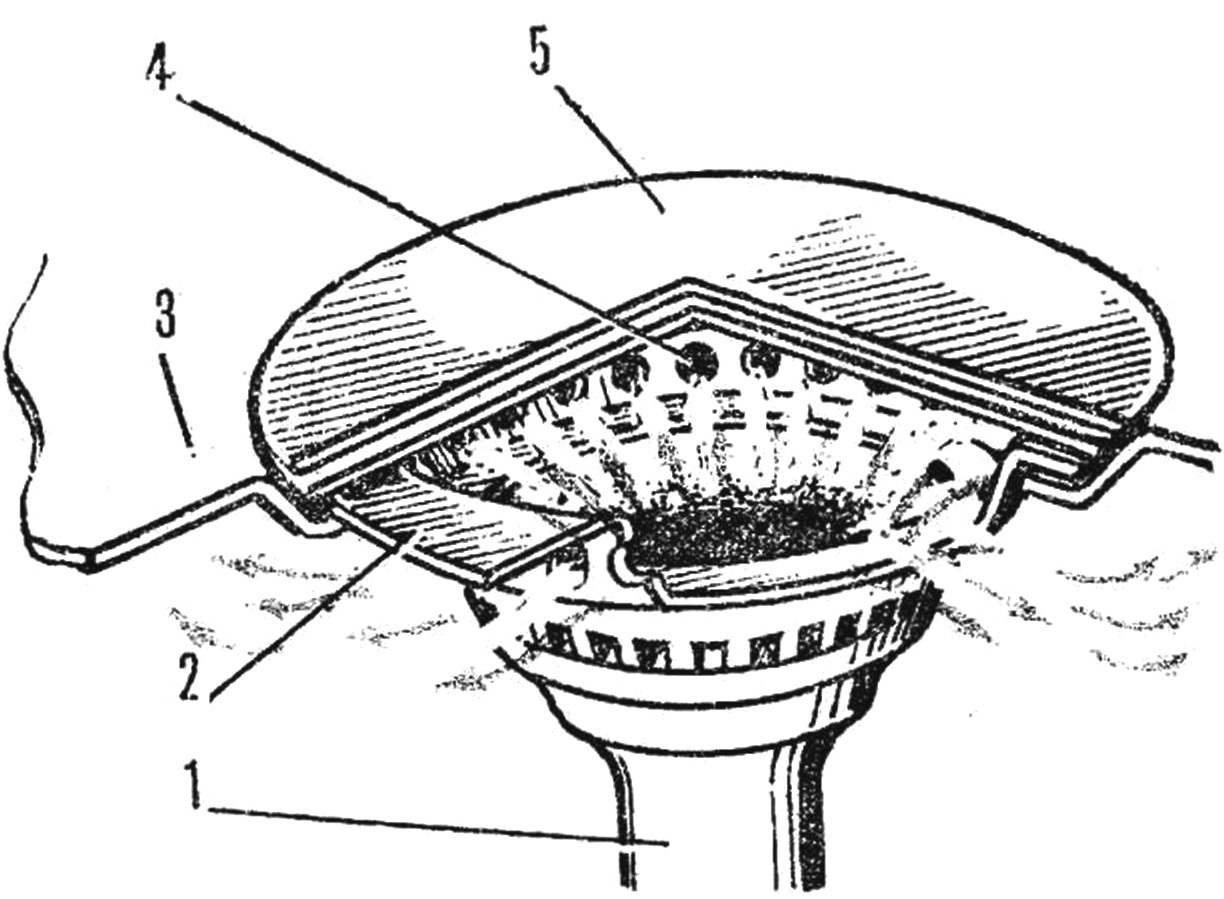

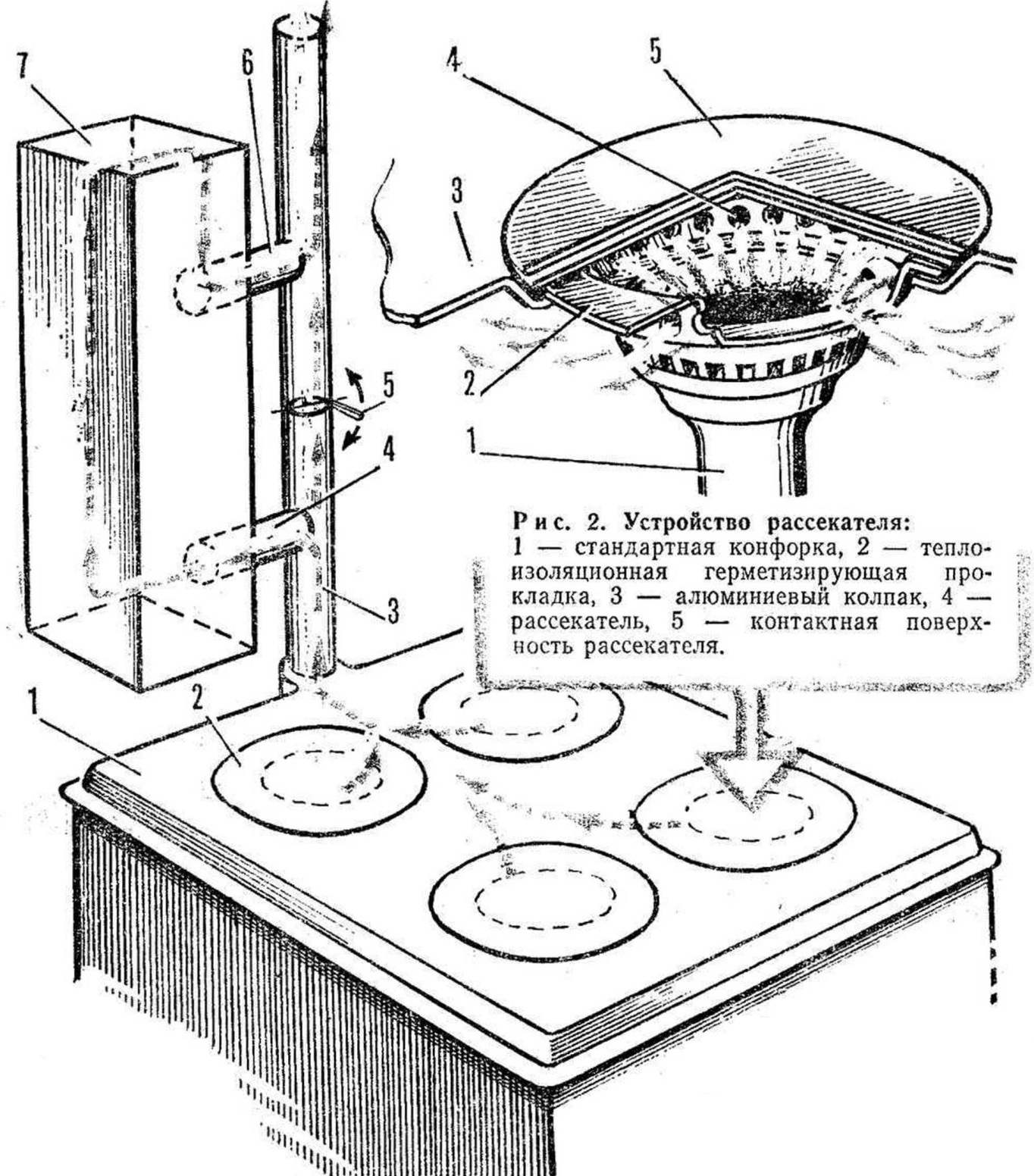

The ideal solution was the complete separation of the flame of the burner (and hence of the combustion products) with the surrounding air. Figure 1: all chetyrehmetrovy plate covered by aluminum cover — square box with a wall height of about 80 mm. edge of the cap tightly covers the sides of the pan. Above each of the burners in the hood there is a round hole covered with a flame spreader is a thin — walled burner of heat-resistant steel. The air required for complete combustion of the gas sucked by the injector of the burner and partially flows through the holes in the pan. The lower surface of the divider is perforated, in the flame of the burner it is heated red-hot, which ensures complete combustion of the gas mixture inside the divider. Glowing divider (or rather, its outer surface) is in contact with the pot or frying pan, reports km of heat harmful gases at the same vertical tube is discharged into a chimney (of course, if he is in the kitchen) or on the street through the window opening or wall. In order for the combustion products entering the room divider is joined with an aluminum cap using a heat-insulating gasket. To light the gas, enough to raise the divider, to light a match and open the tap.

Fig. 1. Schematic diagram of gas stove:

1 — aluminum cap, 2 — pin surface divider, 3 — tube, flue gas in the flue, 4, 6 — discharge nozzles, 5 — valve, 7 — heat-exchanger.

Equipped gas stove can replace hoods, cluttering up much needed kitchen space and also poorly performing entrusted to them “duties”. The fact that the jets of heated air rising from the burners, carries a large amount of clean air food and mixed with it. Due to the significant volume of the mixture is unable to pass through the canal of the chimney. This leads to the fact that a large part of the combustion products, in the end it turns out in the kitchen. In winter, the exhaust air from the room requires a flow of an appropriate amount of air from the outside (from the street), which leads to cooling.

Turning so his plate, I noticed that the temperature of the exhaust in the flue gases is quite high. I thought to throw away such a valuable heat (of course, in winter) at least impractical. What if it disposed of? From thin sheet metal made the simplest heat exchanger is a box of dimensions 200X800X800 mm, now exhaust gases before leaving the chimney, heat exchanger, and the air in the house.

N. BEZBORODOV, Dolgoprudny, Moscow oblast