Summer – the traditional time of repair of apartments. Usually we limit ourselves to upgrade the ceiling, woodwork and walls. But sometimes comes the turn of the sexes is well roofed, well-maintained floors give the room a beautiful view – not by accident driving to a new apartment pays attention not only to the quality of the finish of the walls or joinery, but definitely on the floor. Of course, over time they wear out and need to be updated. If the wooden platform appear in the gap teaser, a crack – they accumulate dust and dirt, taking care of these floors is becoming tedious, time-consuming. Therefore, they must be repaired. and if defects are large – to lay new ones.

Summer – the traditional time of repair of apartments. Usually we limit ourselves to upgrade the ceiling, woodwork and walls. But sometimes comes the turn of the sexes is well roofed, well-maintained floors give the room a beautiful view – not by accident driving to a new apartment pays attention not only to the quality of the finish of the walls or joinery, but definitely on the floor. Of course, over time they wear out and need to be updated. If the wooden platform appear in the gap teaser, a crack – they accumulate dust and dirt, taking care of these floors is becoming tedious, time-consuming. Therefore, they must be repaired. and if defects are large – to lay new ones. Usually they lay directly on the beams when they are located at a distance from each other, based on their boards will not bend when walking. If thin boards or beams are stacked rare, the first to the last placed Pagi, to which is attached deck.

Boards 28 mm thick – top-selling to all residential and public buildings, even. Thicker (36 mm) designed for areas with high load on the floor – gymnastic halls, industrial buildings. Logs are usually placed through 400-500 mm (admissible wood moisture 18%). The width of the lag is taken within 100-120 mm, the thickness depends on the distance between the beams. If the joists are laid on the slab or sound-insulating layer, the thickness may be small – 25 mm, width – 80-100 mm.

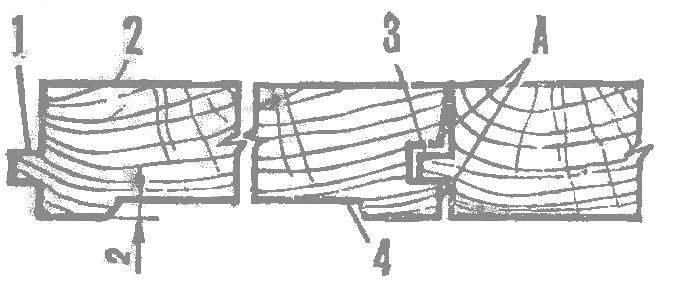

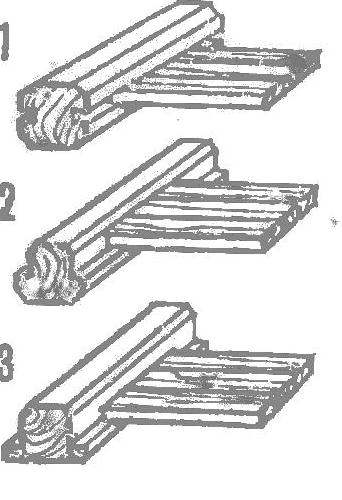

Fig. 1. Floorboards:

1 – ridge, 2 – front side, 3-slot, 4 – produhi; A – beveled edge docking.

When the device of deal floors is necessary to take measures to prevent infestation of wood beetles eucnemidae and house fungus. Therefore, the lower crowns home, sexual beams, joists, boards the rear of the need to handle antiseptic. They have on offer to produce them should be strictly according to the instructions that came with the package.

Water-soluble antiseptic that protects against mold, are sodium fluoride, sodium fluorosilicate, ammonium fluorosilicate, drug VVK-3, XXII and drug MHHTS. Their solution is applied to a timber with a brush or by spraying. Handle should be doubled at intervals of 3-5 hours, strictly observing the safety regulations, work is carried out in a well protecting clothing. Three-percent solution of sodium silicofluoride fluoride FDI, moreover, protect and insects. If they are bred, solutions and chlorophos hlorodana used: impregnated wood or injected into the flight holes.

The underground should be well ventilated, especially during the warmer months. If the soil in the underground crude, it is necessary to arrange a waterproof clay, concrete, laying of roofing felt in one or two layers.

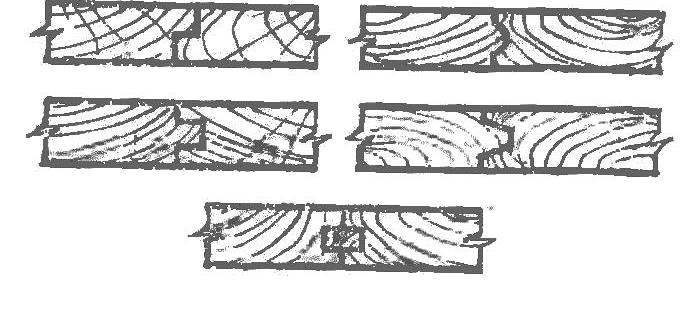

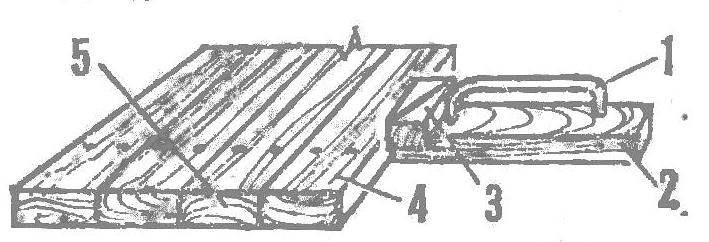

Fig. 2. Types of joint floorboards.

Special milled boards and bars with ridges and grooves are used for carpeting. Boards 28 typically have a thickness and 36 mm width on the front side 68, 78, 88, 98, 118 and 138 mm, respectively, the bars 28 and 35 mm, 45 mm and 55. At the bottom of all of them is selected groove or air holes of 2 mm in height: it not only promotes dense abutting each boards to beams or logs, but also provides reliable ventilation of the space between the two decks at the device of warm double floor. From the groove to the front surface of the boards and bars made small bevel which provides a tight abutting edges of the boards together. It must be borne in mind when laying flooring.

For boards and other boards are available: grooved rebated with a direct thorn, with a thorn segment, trapezoid with thorn and with rail, in the tongue. They planed with one face, do not have air holes, and to lay them more difficult; with a small (only 1-2 mm) tubercle on the beam or lag board swinging. All these irregularities must be carefully removed.

Even more work will require Grinding priests out of the ordinary, often edging boards: will have to abate wane ax, plane faces.

However, whatever the board, with a floor they laid growth rings in different directions: only under this condition, Grinding is a more even, to a minimum and reduces warping.

Fig. 3. Selection boards for flooring.

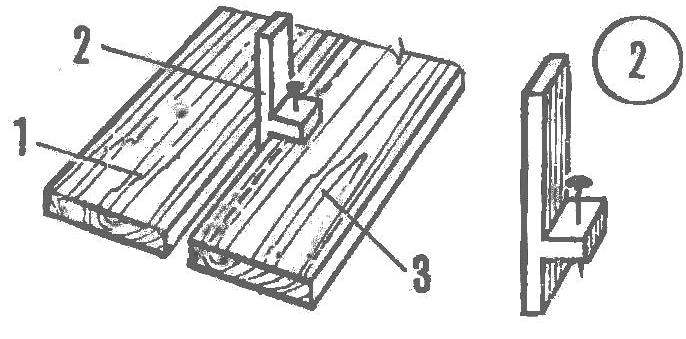

The floors are single and double. The latter consist of two floorings – pure and black (selection), located on different levels. Black floor slabs made of other suitable plates or boards of thickness 50-60 mm. They did not beat, and placed in the selected slots in beams (dowels), shoulders ( “skulls”) or nailed “cranial” bars. The upper left side of the beams for laying the finished floor: it should be well sawdust, skived or additionally ostrogannoj.

Arrange double floors so. First trail black floor, smeared it with clay or lime mortar, dried, and then fall asleep dry coarse sand or fine Shpak – up to half the height of the beam. If sand is used, it is filled with liquid mortar (a layer of about 10 mm), dry well and only then lay a clean plank floor. To this space has always been dry, the floor should be at the corners of three or four vents 0 10-15 mm, closed bars.

If clean flooring without air holes – on top of the beams every 500-600 mm make several cuts deeper than 20 mm for air circulation.

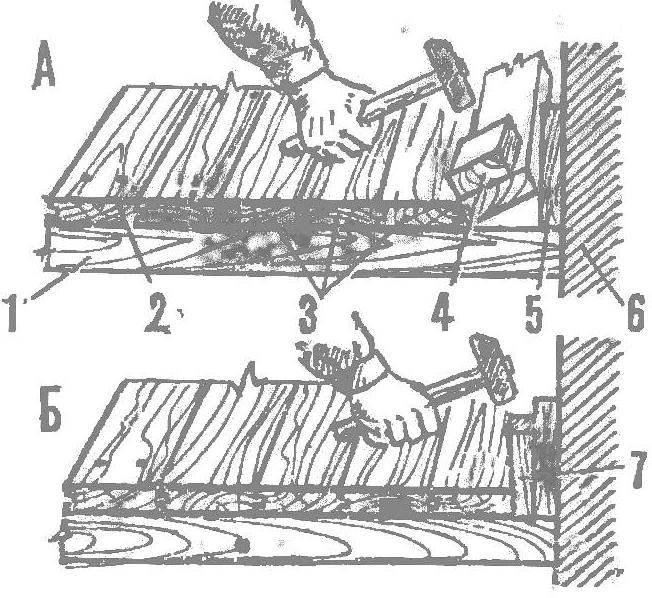

Flooring clean floor of planks with grooves and ridges in the following order. The first slot is placed on the wall is indented to 10-15 mm. To maintain this distance, it is best to apply the so-called calibrated laying plank-specified thickness. They put at least two on the length of the board.

Laid first board fastened by nails, their length depends on the thickness of the boards: they should be 2-2.5 times as long as its thickness. Nails hammer on one and each intersection Lagoi board with, but many prefer to board a width exceeding 90 mm hammer on two nails.

Hats of nails utaplivajut dobojnika into wood to a depth of 2-3 mm, so as not to blunt the tool (plane) in the final planing irregularities. However, to avoid holes in the floor, can be carried out laying of a so-called parquet way, when the nails at an angle of 45 ° (inclined) is driven from the side, the corner ridge, followed waterboarding conductive caps in the thickness of the wood. Having strengthened the first board, it puts a second and groove to the wall and is pushed her to the crest of the last with a hammer through a lining (the bar, the bar) so that the board sat tightly in place along the entire length, and then attach the nails, hammering them first on extreme lag, and then moving to the center of the board. For thicker boards adjacent to each other and there are no gaps between them, dx preloading recommended, since ukpadki second board. Not fixing it in a log or beam drive in the bracket, often in two places, with a space from the board of 100 – 150 mm. Comb protect seal length of 500-700 mm, between it and the staple pierce one or two wedge as long as the second board is not tightly pressed against the previously nailed n. In this state, in the laid board and hammer in nails.

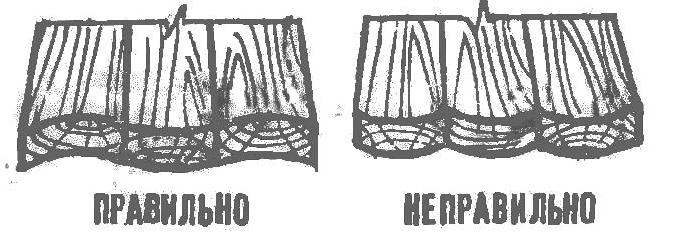

Fig. 4. Marking untreated planks under the joint:

1 – the first board, 2 – dragged, 3 – prepares board.

The last few boards have to be laid not pursing, as in the remaining gap in the wall bracket will not fit. In this case, the board placed 2-4 freely, and adjacent to the wall slaughtered with an ax or a hammer through a wooden pad. To prevent damage to the wall, it puts plywood sheets. When the board is upset at a place between the plywood board and hammer wedges and podozhmut last board for fixing them with nails.

When Flooring from conventional, untreated plants on the boards they have to shave. At first carpentry nastilke them all on one (front) side planed. Then the first of the stacked boards on a cord with a broken line pritesyvayut both edges of the board and nailed to lag. At a distance of 2-3 cm from it and put a second temporarily prihvatyvayut two nails. In the clearance dragged inserted between them (the bar with a nail-prescriber), so that as it moves along the first nail boards left line to temporarily nailed: for this risk and pritesyvayut another edge.

Joiner, stricter Grinding is that the board planed on three sides at once, that is, from the front and along the edges, which is desirable jointing with a little slant to the surface.

Fig. 5. Laying the subfloor:

1 – in the beam groove. 2 – the shoulder ( “skulls”) 3 – nailed on ( “skull”) bar.

Flooring parquet flooring

The most common piece Grinding or mosaic parquet on mastics. It can be performed at the new base of the concrete made with good tie (surface), it is easy to check that the rack length of 2000 mm, between it and the coupler gap is allowed no more than 2 mm.

The label can be carried out and sound-proof fibreboard, if they nastlany accurately, as well as worn-out linoleum, provided that it firmly glued to the ground. B last case selected mastic, firmly engaging with linoleum and parquet.

Block parquet – a strap length of from 150 to 450 mm and a width of 30 to 60 mm. They produce their solid hardwood and softwood thickness 16 – 19 mm. Each plate has a groove on the end face and share a 6 mm deep and 5.2 mm wide, and on opposite sides of ridge 4.9 mm and a height of 5 mm. They docked at stacking ensures reliable bonding strength bars in a single deck.

Fig. 6. Seal the deck:

1 – Bracket, 2 – lag 3 – wedges, compressible 4 – boards. 5 – nailed boards.

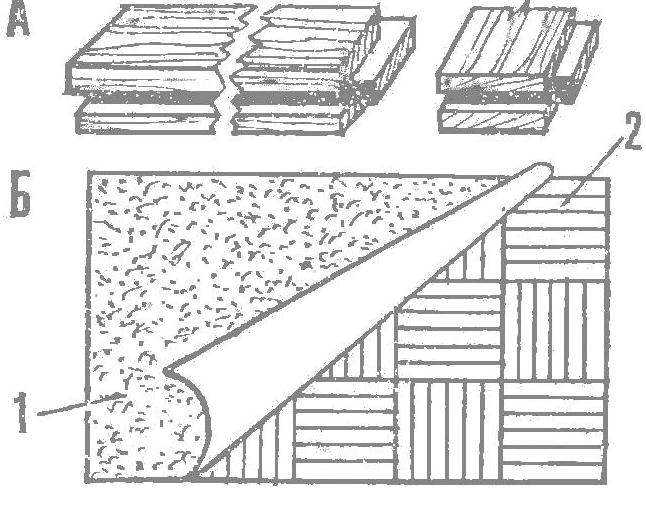

Parquet floor is a small square-shaped panels in two sizes – 400×400 and 600×600 mm; they are collected from the strips 8 mm thick, deciduous – 12 mm. These strips glued face on heavy kraft paper adhesive type dextrin, which is from a small moisture soak, and the paper can be easily removed.

The floors of these boards stacked on mastics on any hard surface. If a block parquet after laying planed, then typesetting has already surfaced, so it is necessary to stick to a very flat surface.

Mastics or adhesives for parquet flooring used several kinds. Of the commercially available bitumen and we can recommend the glue bustilat. Last sold in ready to use form. Some of the mastic can be cooked at home. The material for them mainly serve the oil bitumen BH.

For parquet works better to cook hot mastic: they are convenient in that harden quickly and seize with a coupler through 1-2 minutes – this allows you to just walk on the floor nastlannomu. But they need to work carefully, because they have a temperature not lower than 160-180 ° C.

The bitumen grade used for them or IV with a softening point of 60-65 ° C: it can be used alone or with the addition of fillers – while its consumption is reduced, and the strength of the binder increases.

To prepare the mastic asphalt cut up into small pieces that quickly melted, put in a solid bowl (boiler tank) and heated in summer to a temperature of 170-180 ° C in winter to 200-220 ° C. “Boil” ka bitumen outdoors until long as he does not cease to foam, ie before full dehydration. Prolonged heating and overheating mastic is undesirable because it reduces its quality. Pop The foam and impurities are removed.

Mastics for Filling must be dry, with a grain size not larger than 0.3 mm it is different stone chippings – flue dust, sand, metallurgical slags. Can be used, and fibrous materials; asbestos flour, peat litter, sawdust with particle size up to 2.5 mm. Asbestos humidity should be at least 5%, sawdust, chips and peat – 12%.

Fillers allow to apply bitumens with lower softening point: they create a rigid skeleton in layers and prevent its flow.

Fig. 7. Placing the last floorboards A and B of Poggi:

1 – lag 2 – nailed board, 3 – stacked boards, 4 – boss-liner under the hammer. 5 – wood or plywood lining. 6 – wall 7 – wedge.

Hot mastic should be used in the cooking process, which is not always convenient. Cold same with the right drawing may be stored in a tightly sealed container for up to three months. But they grasped more slowly, this is their fault.

Cold mastic can be obtained from a mixture of bitumen grade BN-1U (65%), white spirit (22%) of turpentine (6%), rubber adhesive (2%), cement (7%). After stirring, a homogeneous mass is easily applied to the base, providing a strong gluing. Mastic dissolved thickened mineral spirits, which is filled with dishes 8 / m volume bitumen is heated, the foam is removed, and all the injected cement mix thoroughly. Then, remove from heat, cooled to 75-80 ° C and under continuous stirring administered to white spirit and turpentine, and thereafter – a rubber glue. Consumption of mastic: 1 kg per 1 m2 of parquet Two prescription mastics; without filler – bitumen BN-111 (75%), gasoline (21%), resin (3%); with filler – bitumen BN-1V (48%), slaked lime / lime pushonka (12%), pulverized asbestos (8%), gasoline (32%).

These pastes are prepared so. Cool dehydrated bitumen is Heated to a temperature of 140 ° C through a grid with cells of 0. 5X0. 5 mm filter into another bowl, chop finely injected resin and, if required, filler, dried to air-condition. The whole was mixed, then cooled down to 80 ° C, the mixture was poured in small portions gasoline ever again stirred until homogeneous and poured into a tightly closable container. Prescription with lime solvent is administered simultaneously with the filler at a temperature of 160-200 ° C. The bitumen

When laying a piece or type-setting parquet on mastic of any subfloor must be ogruntovat for better adhesion primer is composed of 1 part by weight of brand of bitumen BN-111 and BN-1V and 2-3 parts of gasoline or kerosene: fused and dehydrated bitumen cool to temperature 80 ° C, poured gasoline or kerosene and all are thoroughly mixed. Replace gasoline diesel fuel is not recommended. All preparations mastics and primers are held outdoors only, strictly observing fire safety.

Before priming the subfloor is cleaned of dust and dirt and dried. Parquet flooring is made only after the primer is completely dry and forms a continuous film.

Shield parquet laid without any ploys, but the piece allows you to make a patterned floor, patterned. Please estimate, if stacked plank flooring for a variety of room width. If you decide to do herringbone flooring, put out planks along the wall to dry the so-called snake, and on which will be guided: in the snake each lath corresponds to a parquet number. Each row must be stowed so that between walls and the ends of the last row of planks was a small gap, which can be easily blocked skirting better type of fillet. Very well, when the size allows straps to lay a snake from even number. Thus it is necessary to take into account the width, if it is up to 40 mm, it is possible to dispense with the filing of the ends adjacent to the walls. In larger the width of the gap between the walls and extreme laths turns out too big; it does not overlaps the skirting, and boards have to cut at an angle of 45 °. When placed in a series of an odd number of strips of width 40 mm Grinding are what shape the snake. If the width is greater than 40 mm plates, snake shifted by half the length of the strap to one of the longitudinal walls.

Fig. 8. Types of flooring

A – piece strap (riveting), B – inlaid shield: 1 – a sheet of paper, 2 riveting.

In order to save, you can carry on laying of it this way: sawing one lath from a snake half 45 ‘-poluchatsya halves of which are gaining both extreme and number plates, in this case, cutting far fewer exposed bars.

When available parketin fails to lay the snake of integer equal length straps, extreme gain rows of strips of shorter length, and the ends of the wider planks off the saw at an angle of 45 °. Figuring thus laying a plan laid out to start the lighthouse Christmas tree.

Majachnaja tree – these are the first two rows of stacked bars. They lay carefully, strictly on a cord, as closely as possible to each other. The appearance of even a small misalignment leads to a distortion of the figure, the appearance of ending gaps.

Begin by laying an elongated wall opposite the entrance. This is especially important for parquet flooring mastic on the cold working would not tread on the already stacked rows. 8oobsche something desirable least majachnuju tree lay on hot mastic, which hardens quickly, so you can not be afraid of its displacement in the further work. If the on-Steelco made on the cold mastic, then the gap between the wall and the first row of parquet laying wedges to lighthouse tree did not move when laying the next series, waiting for 5-6 days or until the paste hardens. This condition is important to maintain, because all subsequent strips will sit down with their slots on the crest of the previous ones, and this is done with a hammer. The straps fit snugly to each other, the higher the quality of the flooring.

Laying a lighthouse Christmas tree is performed by the taut cord, which should be over the bar, not to lie to them. Therefore, it is tied to the nails driven into the walls of a Christmas tree on an axis in fixed temporarily strips or bars which, after laying the first rows removed.

Majachnye tree should start from the wall, and so that a cord was left a number of bars, and the angles of the right concerned only him working normally rests on the right knee and the movement does not touch the cord. Of course, the snake and the lighthouse tree can give all the best, and in the center of the room, and the rest of the series Grinding conducted first with one, then the other. However, a much more economical and easier to start from one wall.

Having laid completely all the rows, begin to separate the “gaps” in the end walls, reminiscent of a black triangles. They often do so: from whole laths dry gaining square negate it diagonally in half and cut strips on the drawn line. Resulting triangle fill the remaining gaps in the short sides. In order in this case between the strips was not large gaps, they draw in the wall of plywood inserts or wedges.

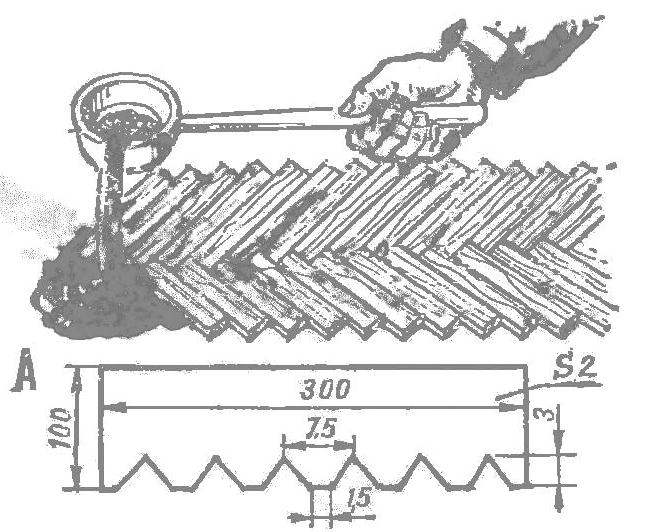

Laying parquet on mastic riveting in the following order. First laid out on the sides of the lighthouse Christmas tree parquet blocks so that they appeared at hand. The mastic is poured on osnozanie in such a way that it is in area slightly larger than the next number, and level it with a single line of the toothed side – from a roofing steel. The thickness of mastic – 0.6-0.8 mm. In such a layer parquet Plachkov easily pressed freely reaching the base and squeezing the air and solvent vapors that come out on the grooves mastic leaves comb.

Each strap has a laid simultaneously tightly pressed against the substrate and at least a comb fit snugly in the groove with a longitudinal and a front side. This is achieved by hammer blows, better wood, parquet.

Floor Covering with a frieze – right next to the side straps – decorates the floor and can be performed as a border, and without it. Fringing fit in different ways: with a ruler, a vein or simultaneously with both.

Freeze several changes and technology of the preparatory work with a snake, first along the long walls of the room expanded a few bars of the frieze, and only between them laid the snake. The size bars for snake and the line is scheduled lighthouse Christmas tree, which is now to be in the middle of the room. In this case the best to do frieze of width such to allow it to abut Suitable strips cut into two equal parts an angle of 45 °.

Majachnye tree and the rest operate as usual. However, extreme strips adjacent to the frieze, first laid dry on the line is carried out on them a straight line, the risk of an awl or sharpened pencil hard. Then, the film is removed, it is precisely saw off ends and only then laid on site already mastic. Remember that inaccurate sawing all forms between the bars of the main deck and the frieze gap that reduces the beauty of the floor.

Flooring mosaic parquet should be made so that the direction of the strips of two adjacent flaps would be mutually indicate instead. Begin laying angle of the room, the more remote from the door. Shields between the walls and flooring and in this case leave a gap, which is subsequently closed molding. To sustain the right direction the first stacking rows along two walls pull two cords (cords) to form a right angle. Can be used instead of cords and rails 15-20 mm, fixing them at right angles to the bottom or walls. These rails will serve in the future a good stop for mosaic parquet boards.

First put the squares on the long and short walls. Then, between the first flaps in the angle formed by them are placed second, and so on, carefully sealing them and pushing in the oil, removing it at the joints with a knife or chisel, immediately wiping the panel dry with a clean cloth. After the work is removed five days with parquet paper, pre-wetted with water, with a brush or a rag. If necessary, place the individual boards scrape and grind, and then varnish or rub with mastic.

Leveling planing and Scratching of the parquet is done mainly on the floor of unit shipments, if it nastlan not very smoothly, or has a rough surface. The first operation is carried out with plows chipbreaker (old name – with a double piece of iron). tool knife should be very well sharpened and directed as necessary to deal with hardwood and remove thin shavings.

Note that the better the planning, the easier and faster then tsiklyuetsya floor. Both of these operations are carried out along the wood fibers. But no matter how dire the knife was sharpened plow, still remains on the parquet surface pile. This pile and remove cycle, cutting off thin shavings. Allegations that Scratching removes all the bumps, minor dents and scratches, is not quite true. This is done by gouging. Softwood little scrape.

For finishing the floor cycle used on short or long handles made of steel hardness, ensuring at the same time preserving and sharpening the ability to direct the work, “burr”, which cuts off the thinnest shavings with parquet. In practice, such cyclic household made of cloth two-handed saws. Cycles on long handles grind without napravki “burr”, they have replaceable blades, which, of course, more convenient. But short of the cycle turns cleaner.

This operation is performed as follows. Working kneels, with a wet cloth or sponge and lightly moistens the surface of the parquet – wood becomes softer. At housewives always enjoyed great popularity oilcloth: practical, convenient cover on the table, whether it is a kitchen dining NLI.

But the industry developed new materials – and now the foot no longer need protection: polyester and other synthetic coatings made countertop and beautiful and durable, and the kitchen reigned plastic.

But kpeenka in no hurry to give up their positions, adapting to life innovations and achievements of the chemical industry. In place of the old fabric-based paint coating n fugitive came synthetics, giving these products lightness, brightness and outstanding wear resistance in combination with such an important quality as thinness, oilcloth approximates to normal tissues, and even paper. Last advantage, perhaps, was the fact that this material has found new applications.

Fig. 9. Parquet Flooring:

A – line for leveling of bitumen.

The first and most popular in the recent years the scope of its use of steel … wall. Elegant, with a variety of patterns and ornaments oilcloth began to compete with the wallpaper, especially in the kitchen, the hallway, in the utility room, bathroom.

There was an interesting opportunity to comprehensive interior design thanks to the introduction of the same pasting that walls, in furniture elements: table cover (with subsequent protection varnish), decorating planes cabinets, asses. Simulated even “mild” cases with the use of such materials, when the frame or the front side are not closed wood paneling and oilcloth, which, incidentally, has made it possible to replace the door on the clasp … “Lightning”.

However, those who conceived the paste over the wall NLI homemade furniture these materials, will inevitably face pressed against the surface and leads in the direction of myself, but only along the fiber. Removable chips regularly cleaned. In a series of works on a long handle with one hand presses the cycle, and the other is its “on”.

Plinth

After flooring and floor-mounted baseboards processing; they close the gap between the boards and the wall. Depending on the shape are different and are attached to the walls or to the floor.

{Loadposition reklama}

When attaching a wooden or plaster walls used nails, hammering them through 600-700 mm with a space from the edges and ends on the 10 to 20 mm. cut “into their heads” for room corners skirting at 45 “. The stone, brick or concrete walls of the pre-punched holes jumper depth of 45-50 mm and clog wooden plugs to dry: here and will be fixed plinth.

Plinth in the form of fillets themselves are often fastened to the floor, especially parquet.

Installing baseboards or fillets themselves should be aware that they are fixed to only one element of construction – either to the floor or the wall. Because the floor laid on sound-proof linings or filling it should not be associated with the walls, so as not to create a so-called sound bridges, under which all vibrations and sounds transmitted to the floor walls, which means – the whole room. So often between walls and baseboards put Fiberboard pads. And fillet normally fixed so that they only lightly touch the walls or separate them gaskets of the same fiberboard.

Often skirting boards are made colored or lacquered. They should be installed after the wall covering paint or wallpaper pasting. The rest are fixed once and stained with sex, often yellow or brown.

A. SHEPELEV