At the first table, as expected, there are four support legs. But they don’t connect with a countertop with both a frame, and pairs among themselves. The legs are made from single boards 600x80x20 mm. from the Bottom they are attached on the supporting cross member of the same plates of length 500 mm with lugs with thrust bearings and reinforcing triangular braces on both sides of each leg for greater stability. Top each pair of connected dual horizontal ties being between them; the entire Assembly is fixed with two furniture screws with wing nuts. On the same screws attached to the rack countertops, as included between the zip ties close to the legs, thereby providing the necessary rigidity and structural stability. The size of the plates-stands 650x80x20 mm. In each rack is drilled with eight screw holes — this allows you to adjust table height and tilt. Connect top-of-rack crossbars that fit worktop dimensions mm 1200x800x20 having one end attached to the rake chains that hold the shield on the crossbars in an inclined position. To this end, the strut sawed ledges under the rail.

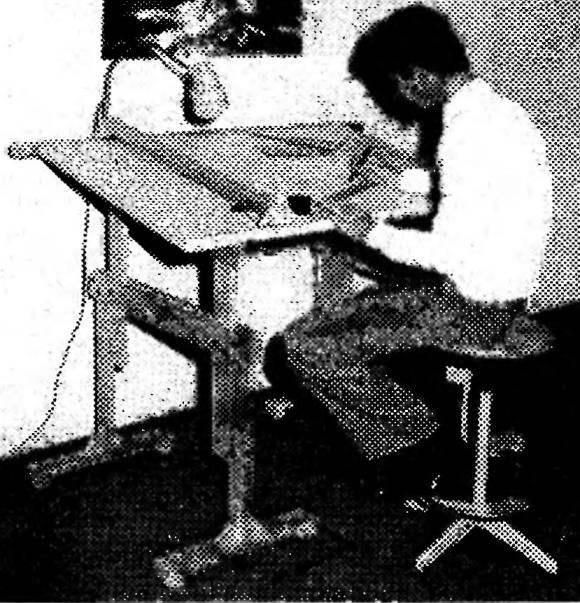

The second table is the Desk is just a different solution basic parts: the legs, as such, it does not. Their role is performed by two of a right triangle.

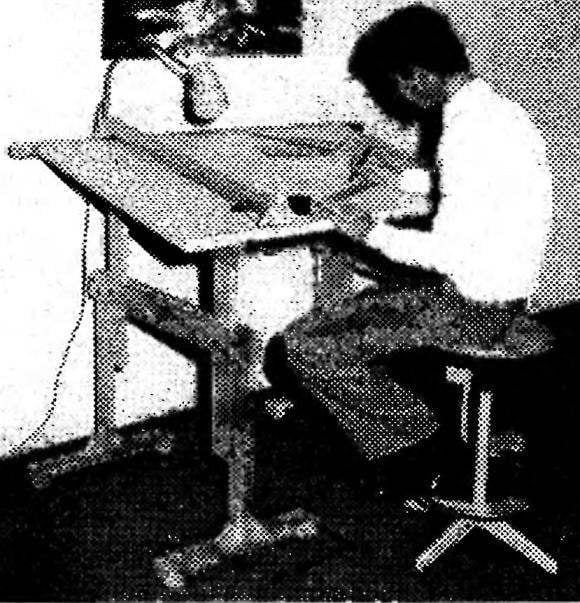

Table variable level and slope:

1 — bearing the cross (4 PCs), 2 — brace, triangular (8 PCs), 3 — leg (4 PCs.), 4 — tie twinset (2 pieces), 5 — strut tops (4 EA.), 6 — cross tops (2 pieces), 7. snow, 8 — tabletop.

Preparation of parts of the table-desks to the Assembly.

Table-Desk:

1 — top, 2 — panel stiffness 3 — bar-footrest, 4 — crossbar countertops reference, 5 — Board external parts of the supports 6 insert parts of the supports, 7 — Board external struts, 8 -insertion of braces, 9 — Board external vertical parts of the supports 10 insert vertical parts of the supports, 11 — Board to the external horizontal parts of the supports, 12 — insert horizontal parts of the supports, 13 — holes for tilt adjustment of the countertop 14 and the fixing struts pin (nail).

Table details of table-desks

(Item numbers are given in pattern)

They can be made from a wooden bar of suitable cross section, but it is better — from a package of plates. This option has undeniable advantages. And not only in a greater availability of material. The main thing is that by manipulating the three planks of different lengths, it is easy to swivel and the desired groove on the ends and even in the middle of the workpiece without any cutting or gouging. This creates the spike and the cap in the intersection of the horizontal and vertical parts of the supports, and the spikes on their ends beneath the junction of the inclined part. The latter, in turn, in the same way formed lugs on the ends and the groove-slit at the lower half. The same can be said about the brace: sliding the middle plate relative to the outer derived one side spike on the other — hinge-lug. His tongue brace moves along the inclined slit of the support and fixed in one of its holes, setting the desired inclination of the table top.

a triangular support connected at two locations: bottom — bar-footrest, rear panel stiffness. The joints are provided with either plug-in round thorns (pegs), or metal parts or wooden wedges.

Plates constituting the support and the brace are connected together in any convenient way, from the churning nails to bonding under a press (a carpenter’s glue, casein, PVA). After production they are processed sandpaper and polishing (if you intend to cover furniture varnish) or putty with the subsequent colouring. The same applies to countertops. If it is out of thick plywood, it is possible to cover it with varnish because the wood has a beautiful pattern. And a case of some boards or chipboard is better for painting, had previously been thoroughly polished it with emery paper, and polished with proshpaklevat again. The paint is preferably applied in several layers with intermediate drying within the time frame specified on the label of the jar.

A good aesthetic effect can be achieved by the application of colored enamels. So, if the tabletop and its supporting cross member brace paint in a single color (e.g., purple), and a triangular support together with the panel rigidity and a lower strap in the other, say, purple, in conjunction with the original design it will immediately make a homemade furniture “brand.”

Recommend to read THE PIPE DOES NOT COLLAPSE Thin-walled tube of soft metal when you try to bend often creased. To avoid this, they are usually pre-stuffed with sand. With the same purpose, you can use another method: navit on the... SNOW “PLANE” From a young age was fond of technology and like most boys, dreamed of being a pilot. But, like many, for a number of reasons they did not, and acquired the specialty of a mechanic....  It happens, unfortunately, that the student no home of his Desk that he would be doing homework, playing, making. Meanwhile, the construction of such a table can be so simple that you can make it under the power and home handyman. Enough to see the post here to the options proposed by the Hungarian magazine “Earmaster”. This is two tables that have additional facilities compared to normal desks.

It happens, unfortunately, that the student no home of his Desk that he would be doing homework, playing, making. Meanwhile, the construction of such a table can be so simple that you can make it under the power and home handyman. Enough to see the post here to the options proposed by the Hungarian magazine “Earmaster”. This is two tables that have additional facilities compared to normal desks.