It is with such outbuildings we introduce readers in today’s issue of “Club home of the masters”.

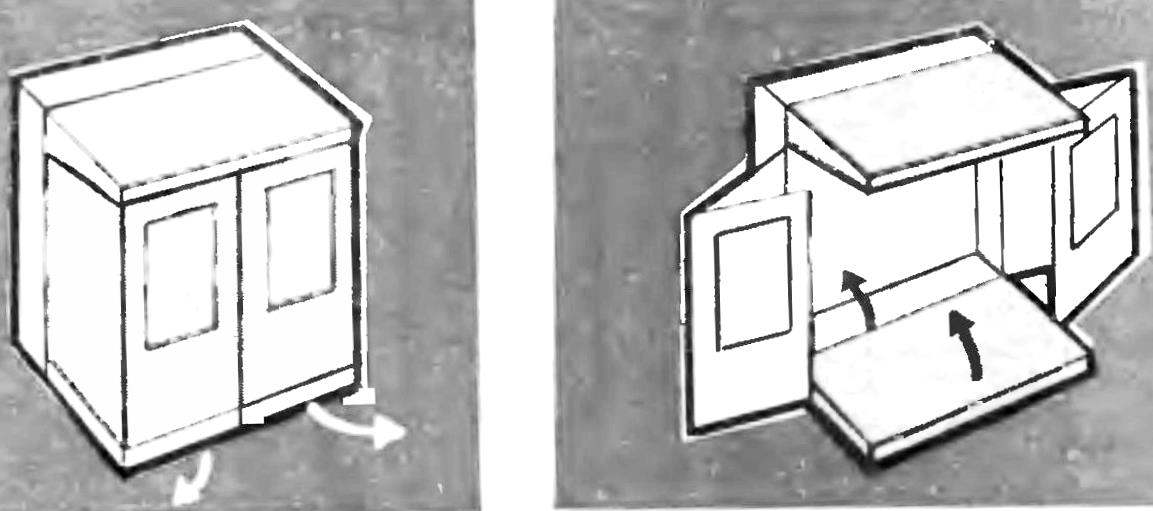

Foldable shopping block wooden panel, dimensions: in the disassembled position 2200X1300X2300 mm, and assembled in — 2200X300X2300 mm. This transformation is particularly convenient for the workshop. Because, as a rule, all work in the garden are produced in the warm season, and in winter the Studio is not in use. Therefore, it can be removed. The extension can also work as storage for seedlings in the spring, or harvested but not yet exported harvest in the fall.

Before you begin construction hozbloka, you must choose which of the walls of the house it is better to attach. Preference should be given to deaf (no Windows) the wall located on the Northern, North-Western or North-Eastern side of the house. In the selected location for the wall are mounted two vertical bar section 100X100 mm, to which are nailed wall supporting frame. They are the basis for all other mobile elements, which are collected separately. To the upper inclined ends of the walls nailed the frame of the shield, which is then coated with a metal roof. From the main facade amenities under the edge of roofing iron enclose a strip of sheet rubber with the release of 300-400 mm. It serves to protect from atmospheric precipitation in a lowered position of the folding portion of the roof.

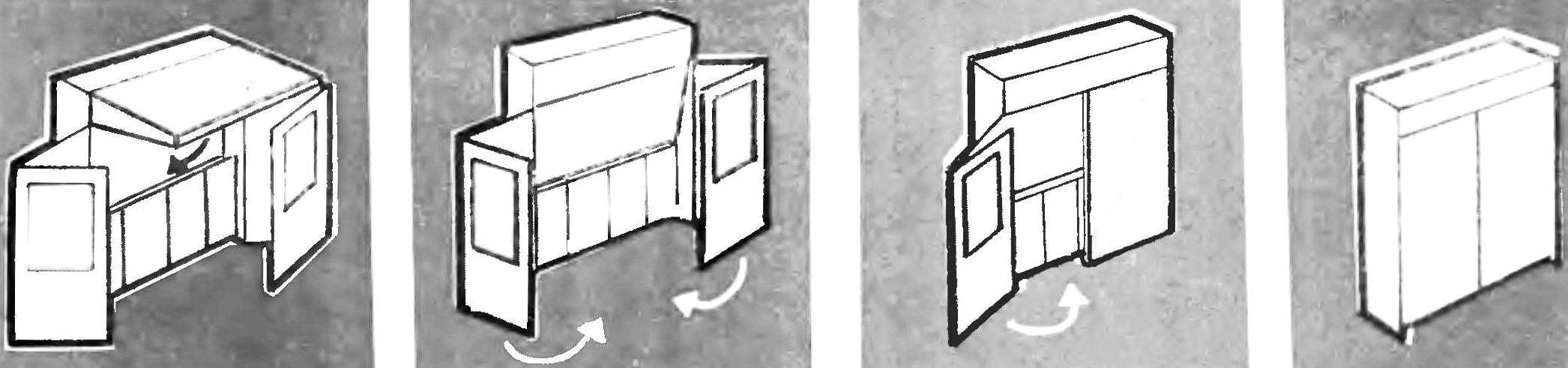

Foldable amenities building-Annex (A — omit the section of the roof, B — twin doors, In lifting a small section of the floor, Mr. most of the lifting section of the floor):

1 — metal roof, 2 glazed doors, 3 ground bar, 4 — floor boards, 5 — M12, 6 — rail mounting wall of the main frame, 7 — a wall supporting frame, 8 — omit the sidewall of the roof, 9 — timber frame canopy, the 10 — panel-door, 11 — beam purlins, 12 — glazed door, 13 — bearing beam, 14 — rubber gasket, 15 rubber band, 16 — hinge, 17 — door handle, 18 — lag, 19 — metal corner strap, 20 — Board side ground strap. I — hinge rotating part of the roof, II — hinge sexual shield III — schematic of rubber tape (POS. 15) in the open (left) and folded (right) position, water supply without.

Next, collect all panel rotary elements. Drop the roof is assembled from two side walls with holes for hinges, the two load-bearing beams and sheathing. Top the entire surface is covered with roofing iron. Omit the part of the roof attached to the walls of the load-bearing frame bolts M12 with washers and lock nuts. Free edge attached to the visor of rubber attached to the roof of the rotating part and fixed with screws and a metal plate.

Paired doors consist of two wings: a dull and glazed, connected by hinges. Each leaf is collected from grooved boards (sexual slats) with a thickness of 28 mm. Glazed sash already a little deaf for convenience when cleaning amenities for the winter. Paired doors are attached to the walls of the carrier frame by hinges. In the working position of the construction of deaf doors are side walls, and glazed fulfill its intended purpose.

Floor amenities consist of two hinged panel elements collected separately. Each panel is made from two supporting bars, side ground boards, log and plank flooring. Each shield element is attached to the wall carrier frame with bolted joints, as well as the lowered part of the roof. To the floor has not dropped below the required level, under the angles necessary to bring a simple Foundation of bricks or logs are tarred up to the level of the lower edges of the bearing walls of the frame.

All moving parts of the utility unit in the working position are fixed simple latches window latches. For constipation design for the winter to a dull door shutters conventional screw eyelets for a lock.

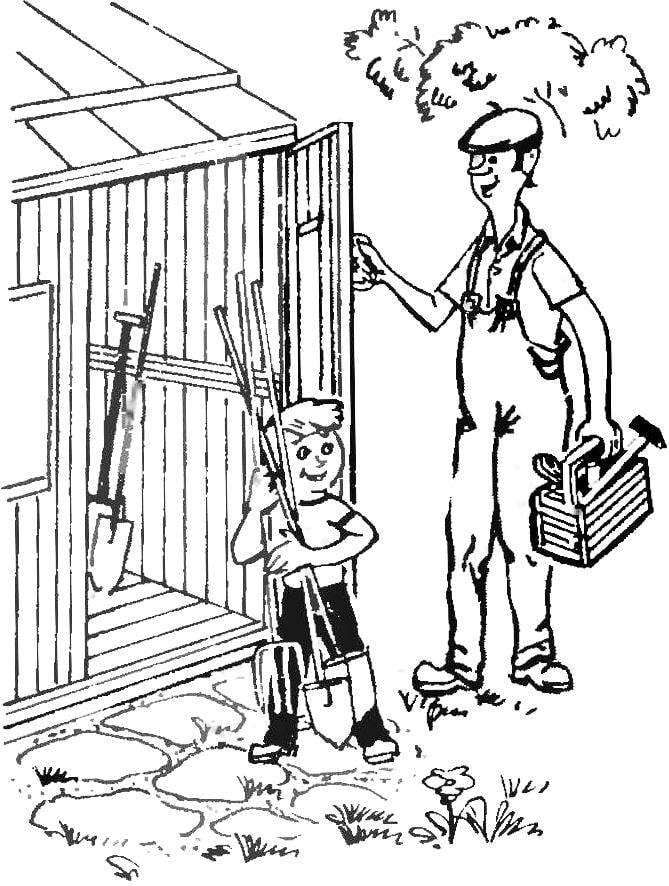

Recommend to read SECURITY ALARM This is a safety alarm device (SLD) is designed to automatically alarm (electrozone) in the case of penetration of unauthorized persons in the protected object — an apartment, dacha,... DUTCH-STYLE POTATOES The experience of potato growers shows: Dutch technology for growing root crops is the most effective, with minimal labor costs. The rows are clean and even, and the harvest is excellent....  What outbuildings do not see in the garden or suburban areas! Most often it is a tiny shed, located at the far end of the site, or a large economic unit, combined with a summer kitchen. The disadvantage of such designs is the considerable consumption of lumber. And most importantly, what they take away precious space from the garden. However, these problems can be solved if maintenance was to make an extension to the house. Folding the shed design will be convenient for the workshop.

What outbuildings do not see in the garden or suburban areas! Most often it is a tiny shed, located at the far end of the site, or a large economic unit, combined with a summer kitchen. The disadvantage of such designs is the considerable consumption of lumber. And most importantly, what they take away precious space from the garden. However, these problems can be solved if maintenance was to make an extension to the house. Folding the shed design will be convenient for the workshop.