Most of its parts are collected in the nodes using plug-in round thorns on glue (carpentry, casein, PVA). Dock first sidewall with the bottom and top, align perpendicular to the installation planes and the equality of the diagonals of the resulting boxes. Then hung the back wall and the bottom of the front ground Board. It must be stressed that with the installation of the rear wall of the design gets final hardness, and thereafter, no correction is impossible.

The narrow panel under the ledge of the corner of the kitchen can be screwed with screws to the small sidewall and support the rear rack. The front Desk made up of two bars. It carries a complex load: gives additional support to the top, two horizontal guide slides extendable drawer, front panel and door. Set strut Assembly with horizontal bars on the spines, inserted with adhesive into the through hole of the tops and bottoms. The same is attached and the guide Board of the drawer.

Assembly of all parts of the hull will be safer if the mating surface pre-lubricated with glue and allow to dry.

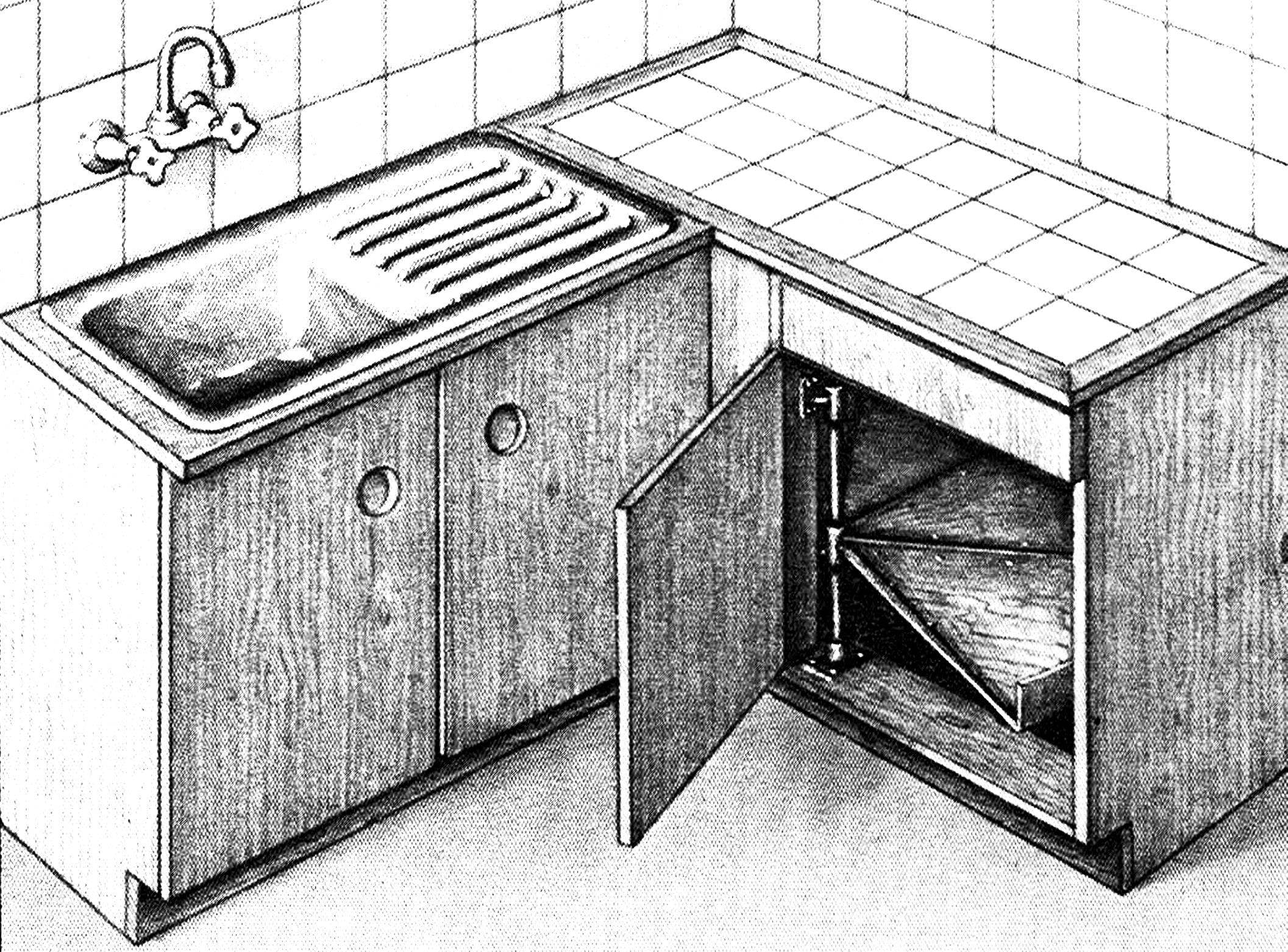

Fig. 2. The body of the table:

1 — front panel, 2 — rail frame, 3 — ceramic tile, 4 — counter, 5 — panel projection 6 — additional stand, 7 — a guide box 8 is a support bar box 9 — additional leg, 10 — support rails drawer, 11, 21 — side panel, 12 back wall, 13, 20 — base plate sidewall, the 14 — door 15 — a flange (thrust bearing), 16, 17 rack, 18 — underbody, 19 — ground Board. A — the top corner of the table.

The front panel also gives the structure rigidity. From mating with her she connects with a round plug-in thorns. The exception is the worktop: it is wider than the box, so it can be attached only to the upper edge of the panel, but also spikes that pass through the tabletop. Given that the front panel is covered neighbouring fitment of the kitchen and not visible, the rest of the spikes may also pass through without stopping them for simplification.

Side table fulfill the role of the support legs. They are made from wood laminate, because this material is afraid of water, the bottom sidewalls attached to the support bracket. Under the additional pillar is set and additional leg — cut out of the same bar that was used for the rack itself.

Countertop edging frame of Reiki, which rises above the surface to the thickness of the tiles. The groove in the rail may be selected using a circular saw or a special cutter. The frame is mounted on the table top with glue. And Reiki with top be sure to cinch the clamps until the glue hardens.

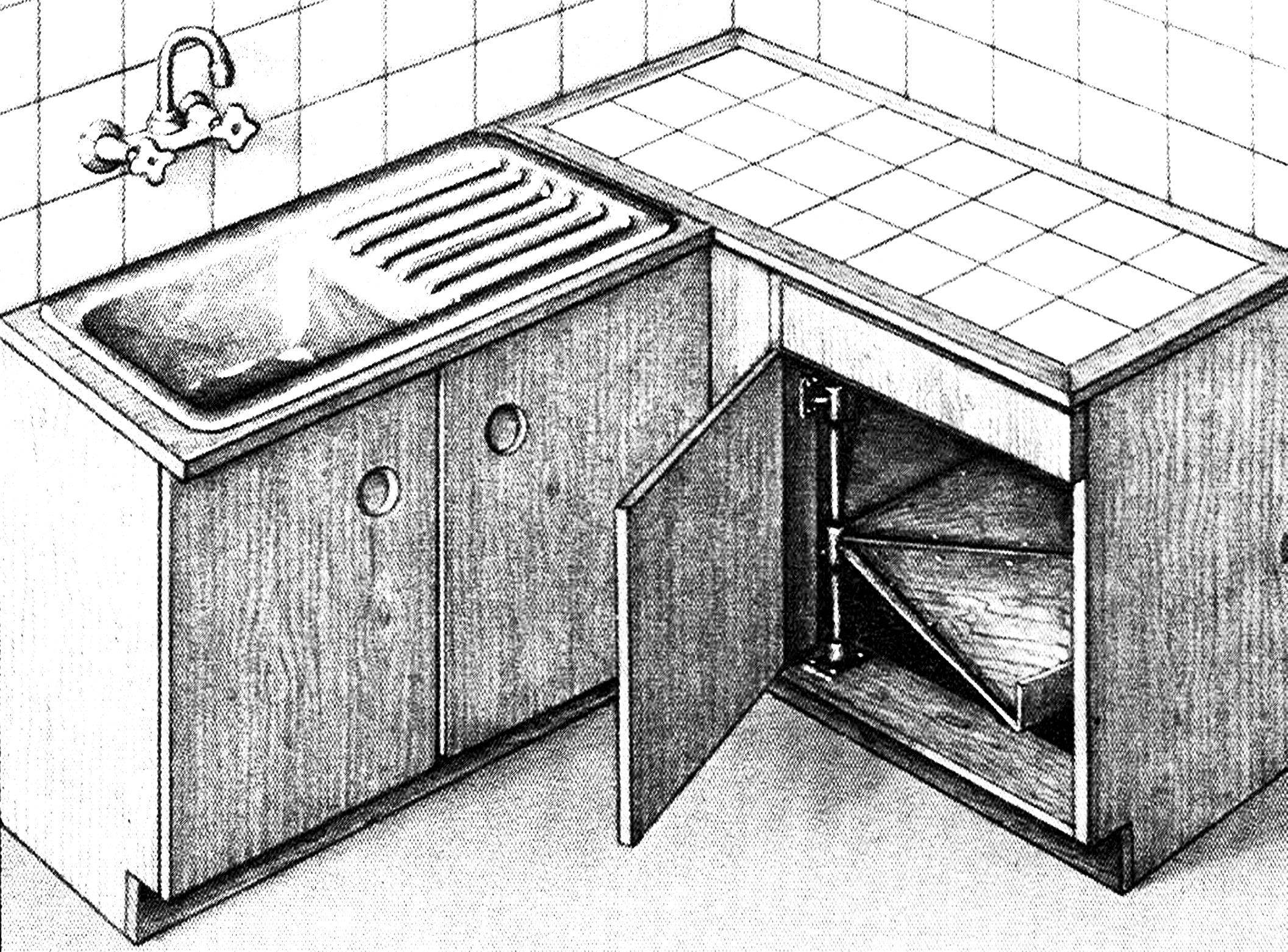

Inaccessible part of kitchen table will be within reach if the shelves are in it to make a semi-circular and rotating.

Inaccessible part of kitchen table will be within reach if the shelves are in it to make a semi-circular and rotating.