Many readers of “M-K” is familiar with epoxy is an excellent material for wikileak almost universal glue, perfect binding for any kind of fillers. But not all obviously know that epoxy resin has wonderful ornamental material.

Many readers of “M-K” is familiar with epoxy is an excellent material for wikileak almost universal glue, perfect binding for any kind of fillers. But not all obviously know that epoxy resin has wonderful ornamental material.

But first a few words about the resin. It is of two grades, ED-5 and ED-6. Both are composed of two components, resin and hardener, which before operation thoroughly mixed in the ratio of 7:1.

The curing time of the resin is from four to twelve hours, depending on temperature, concentration of curing agent and mix volume. In large volumes due to self-heating of the mixture in the polymerization of the resin hardens very quickly, and sometimes even, as they say, “burned” — very hot, foam in the form of dirty foam solidifies, becoming unusable. So, if you want to pour the resin a large amount, it is necessary to put the vessel in cold water, snow, ice.

AS IN AMBER

Entomologists, Amateurs may be advisable to retain the caught insect is not rare in boxes with glass top, and drenched in epoxy resin, then they can be viewed from all sides — top, bottom, side.

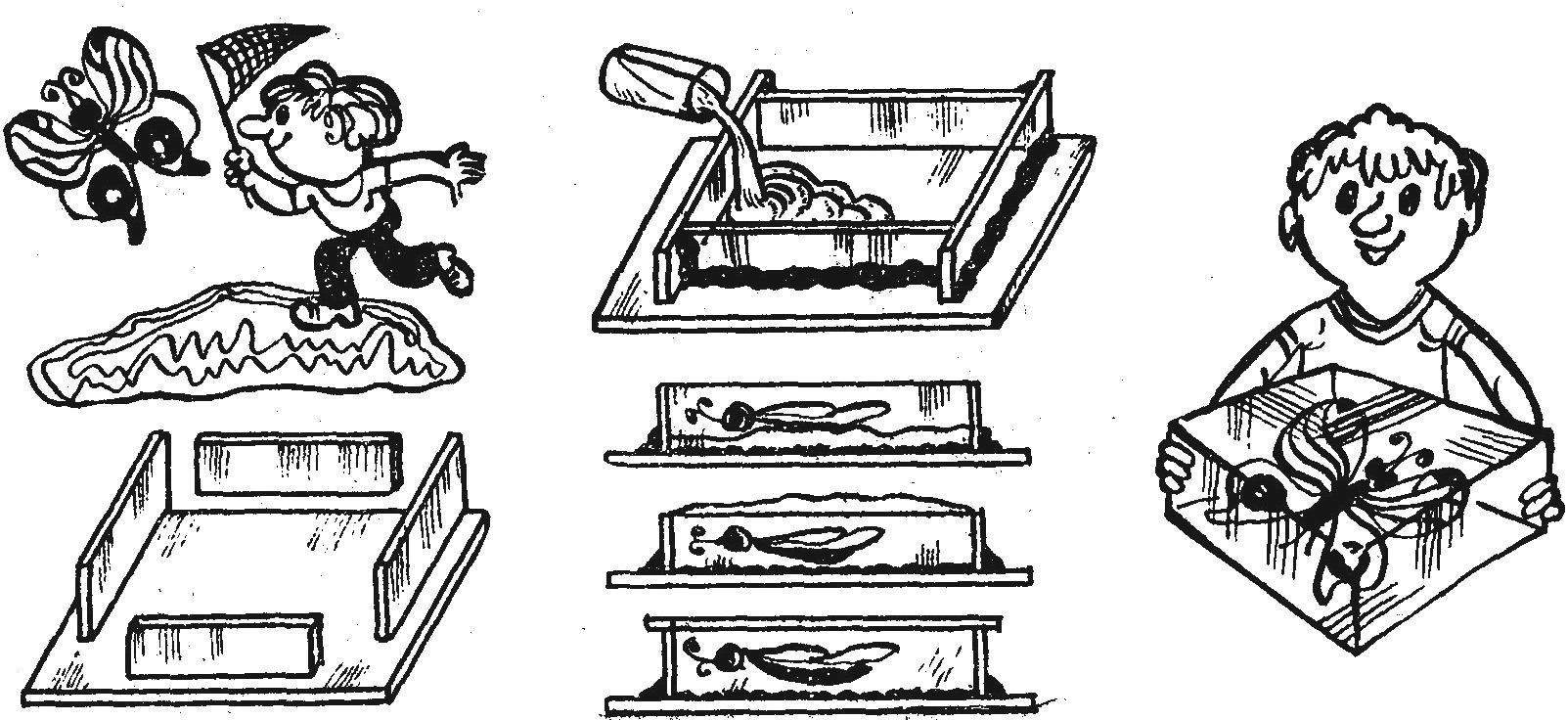

Casting insects in resin is produced in a collapsible form plexiglass: sealed with plasticine four sidewalls, bottom and cover.

In the form of about half of its height filled with resin, and its surface is carefully Packed carefully expanded the insect. Make sure that under it had no air bubbles.

Fig. 1. The sequence of manufacturing epoxy “packaging”.

After the first coat is almost cured, the final fill. The resin should be poured to the top, to form a convex meniscus on its surface. After this form carefully covered with a lid (don’t forget about the air bubbles!) and is left alone to fully cure. The next day take the form of: epoxy absolutely not adhesive with plexiglass, so the shape can easily understand, and you will remain gleaming polished faces of a light honey colour with a block buried in it insects.

PORTRAIT-SOUVENIR

Fans of photography can you recommend a way to finish portraits using epoxy resin. The picture is cut out from the contour of the head and is attached using the same resin on the pre-fanerovannoy valuable wood plate. Then, the entire surface with a photo covered with a layer of epoxy resin and kept for 20-30 min, the resin is partially absorbed, and, if necessary, covered with resin again. Next, the surface is covered with a plexiglass plate, tightly pressed to remove air bubbles with a sheet of thick plywood, which is a heavy load of iron, dumbbell, etc.

Fig. 2. The design of the portrait-souvenir.

After curing, the resin is separated from the plexiglass surface.

The final step is cropping portrait of a preselected contour and finish of ends: sanding and coating them with varnish or paint of suitable color.

EPOXY NECKLACE…

Lovers of jewelry work you can offer to do some nifty trinkets from the “amber”, which successfully fulfill all the same epoxy resin.

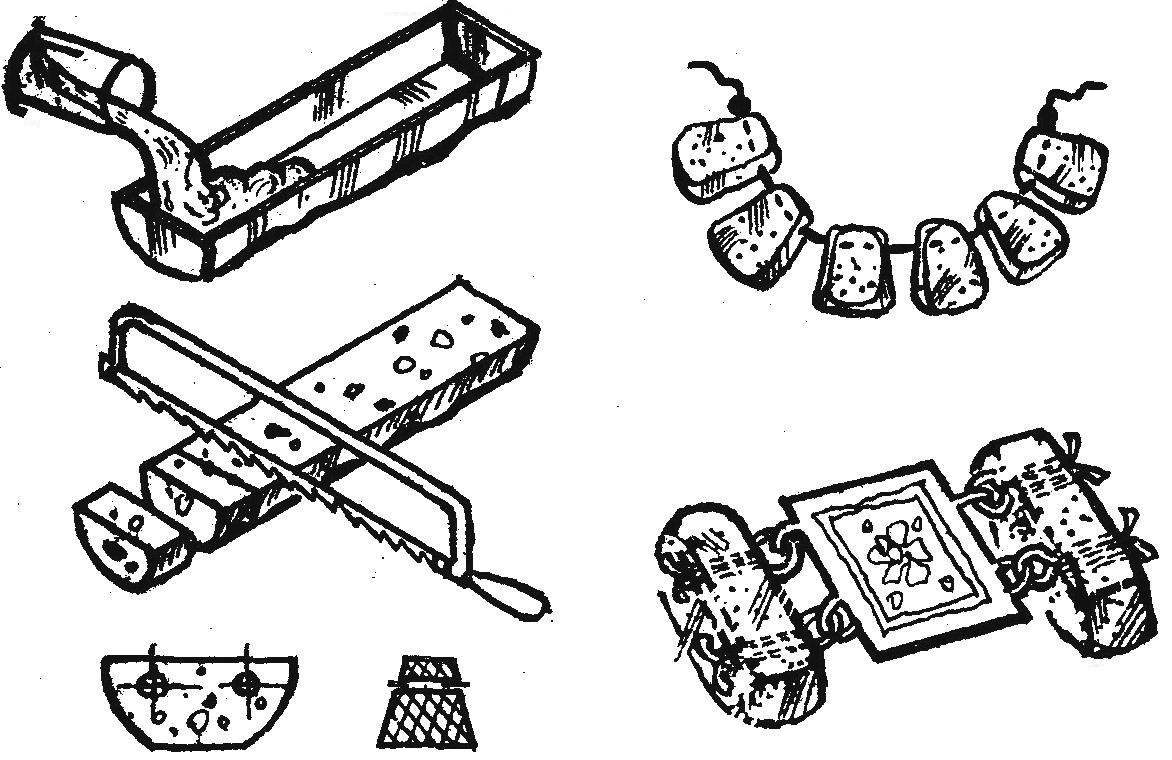

For making bracelet or necklaces you will need, in addition to the epoxy resin, and Plexiglas, a few pieces of sheet brass and brass or copper wire.

Gently heating a sheet of plexiglass over gas or tiles, bend it into a trough (better irregular shape). The ends of the gutters fill with plasticine and pour in the slit of the resin. To produce an imitation amber resin surface in different places drip a few drops of water, a few drops of a medium red, brown and yellow flowers and two or three movements match gently stir them in resin. From water produced streaks of milky, and the nitro — each its hue. Good effect also makes the shading of the pieces of previously prepared resin, multiple stained by one of the above ways. In this case, the pieces of tinted resin is crushed with a hammer, and laid in a trough shape and filled with resin.

Fig. 3. “Amber” of the workpiece.

After polymerization, the casting removed from the mold and cut into segments. The ends of the segments are polished and drilled using a simple conductor two holes in each.

Segments are going in a bracelet or necklace using silk or nylon thread, and to the extreme segments fastened clasp of polished sheet brass. The decoration is ready.

I. EVSTRATOV