In our time, the quantity of waste paper has sharply increased, and mainly at the expense of “disposable” literature in addition to Newspapers and magazines in mailboxes is many leaflets, all sorts of campaigning materials, etc., and — free. Sin not to use such gifts.

In our time, the quantity of waste paper has sharply increased, and mainly at the expense of “disposable” literature in addition to Newspapers and magazines in mailboxes is many leaflets, all sorts of campaigning materials, etc., and — free. Sin not to use such gifts.

In the Chelyabinsk club “Russian craftsmen” realized this long ago and developed a technology for the manufacture of paper pulp, fuel briquettes (approximate size 290x170x100 mm). The duration of combustion of the briquette is about two hours, and the heating value is 2 times higher than in coal. It is also important that, after the combustion of conventional Newspapers is 80% of the ash from briquettes is only 5%.

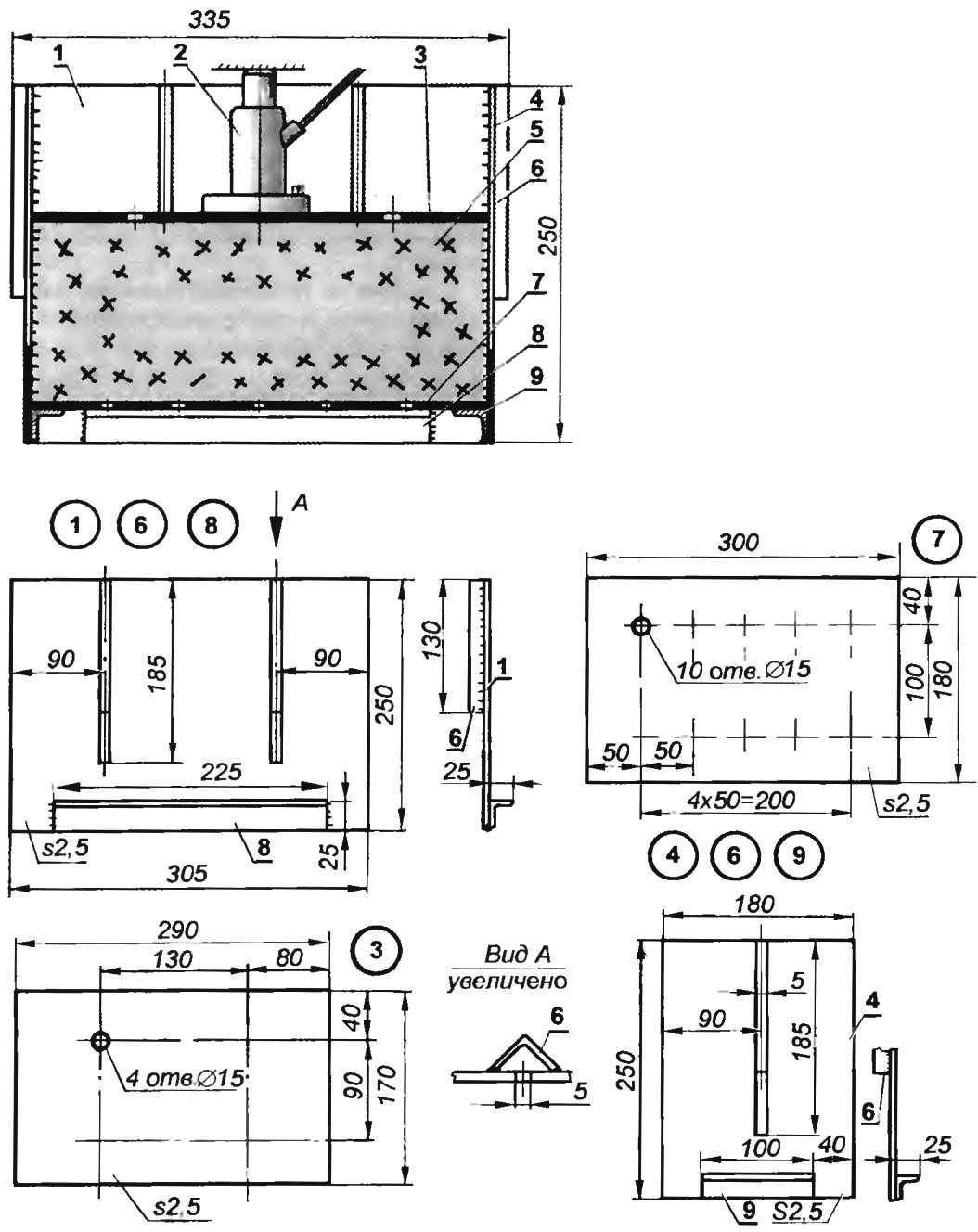

To obtain a printed “wood” you need to make a simple press, a version of which is shown in Fig. Of course, the size of the structure can be adjusted depending on the size of the heating device.

Press for making briquettes:

1 — the big wall (steel sheet s2,5; 2); 2 — Jack; 3 — cover (steel sheet s2,5); 4 — small wall (steel sheet s2,5; 2); 5 — paper weight; 6 — strengthening of walls (area 10×10; L130; 6 items); 7 — bottom plate (steel sheet s2,5; 2 ). 8,9 — brackets of the bottom (area 25×25; 2 PCs.)

The body of said press consists of two large and two small walls, tops and bottoms. Holes drilled in the latter for discharging moisture. With the same purpose in the walls made cuts (round holes will not interfere with the recess of the briquettes from the press). So as not to disturb the strength and stiffness of the walls, zones of cuts on the outside corners strengthened by 10×10 mm. For installation from below the bottom wall welded brackets-popki 25×25 mm; wall welded together in a rectangular box.

Force element press — car Jack. In the manufacture of briquettes of paper pulp (Newspapers, cardboard, etc.) crushed and soaked for 10 — 12 hours. Then in the box press on the supporting angles-brackets fit the bottom, it is wet paper pulp and the top cover, which is provided by a car Jack. Under its influence, the water is squeezed out from the pulp through the holes in the bottom and the cover and through the notches in the walls. After removing the efforts of the box, turned around and pushed a paper briquette. Drying time 5 — 7 days, after which the briquettes are ready for use.

S. HAMMERS, Chelyabinsk