In mechanical engineering, and especially in the construction of the pipe installation is often associated with the need to weld them to the flanges or rings. To maintain precise perpendicularity them to the tube axis is not less important than to achieve high quality weld.

In mechanical engineering, and especially in the construction of the pipe installation is often associated with the need to weld them to the flanges or rings. To maintain precise perpendicularity them to the tube axis is not less important than to achieve high quality weld.

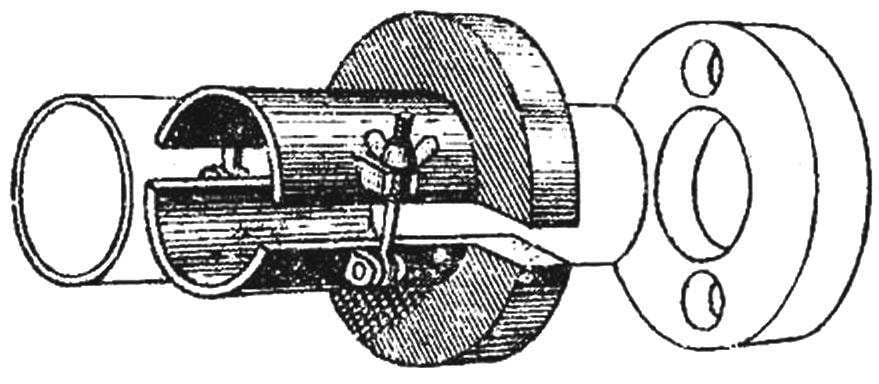

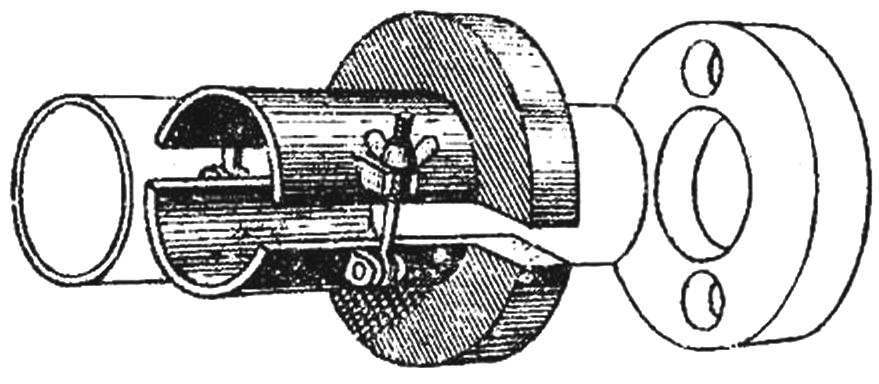

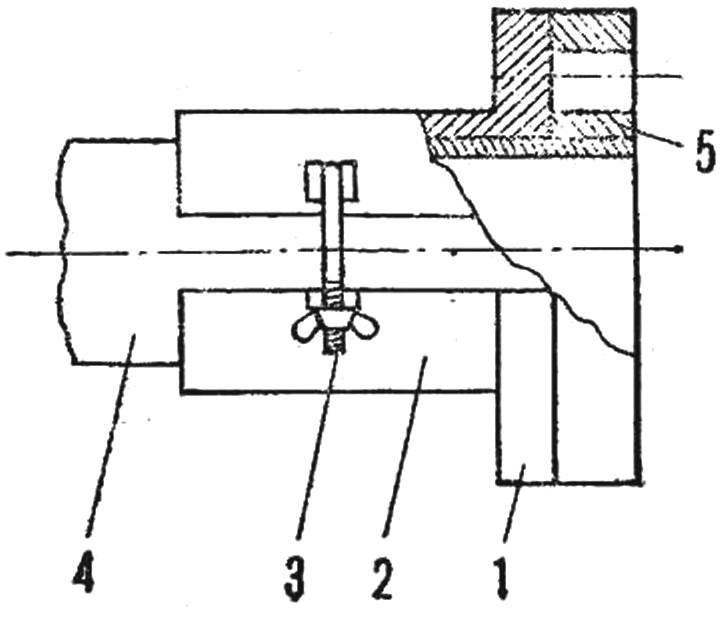

To ensure not only the accuracy but also the speed of performance, innovators Nikolaev I. N. Kozlova, I. P. Malygin, D. P. pacuk suggested that the original fixture — detachable cuff: two hinged half-rings — guide, combine the split bushing. This kind of conductor is approaching or is put on a pipe and secured with the pinch bolt. Then to the ends of its halves pressed tightly mounted element and through the slits of the sleeve prihvatyvaya welding. Final welding is performed after removing the bushing with the half-rings.

The flange before welding:

1 — loop, 2 — split sleeve, 3 —clamping screw, 4—pipe, 5 — flange.