Scoop for garbage collection — it would seem that can be easier. But no, in this elementary product their problems. In stores sold plastic shovels (one-piece) and with a metal bucket and wooden handle. And those and others to be unreliable: break on the bridge at the junction of the handle with the vertical rear wall of the bucket. Is inadvertently pressed a little harder to scoop semi — Yves plastic crack is formed, and a metal jumper — plastic deformation. Over time, the defects accumulate, and the result is failure.

Scoop for garbage collection — it would seem that can be easier. But no, in this elementary product their problems. In stores sold plastic shovels (one-piece) and with a metal bucket and wooden handle. And those and others to be unreliable: break on the bridge at the junction of the handle with the vertical rear wall of the bucket. Is inadvertently pressed a little harder to scoop semi — Yves plastic crack is formed, and a metal jumper — plastic deformation. Over time, the defects accumulate, and the result is failure.

I, like many others, this trouble has not bypassed. “Burying” a dozen scoops of the purchase, decided to make my own — durable, reliable and technologically advanced. The result is a scoop of 3 parts: the handle, bushing and bucket.

Handle — hardwood; I turned from aspen billet on a lathe. (However, about lathe loudly. Just in my small home workshop a fixture on the base of drill for turning small wood parts.) After making it I sanded and coated the furniture with lacquer. The handle turned out beautiful and comfortable.

Bushing and bucket was made of sheet steel with a thickness of 0.5 mm followed by painting nitroenamels (and you can use galvanized roofing iron). Thickness 0.5 mm — optimal: it is sufficient to ensure the necessary rigidity of the whole structure, on the other hand, makes it quite easy to make bending operations in forming the details.

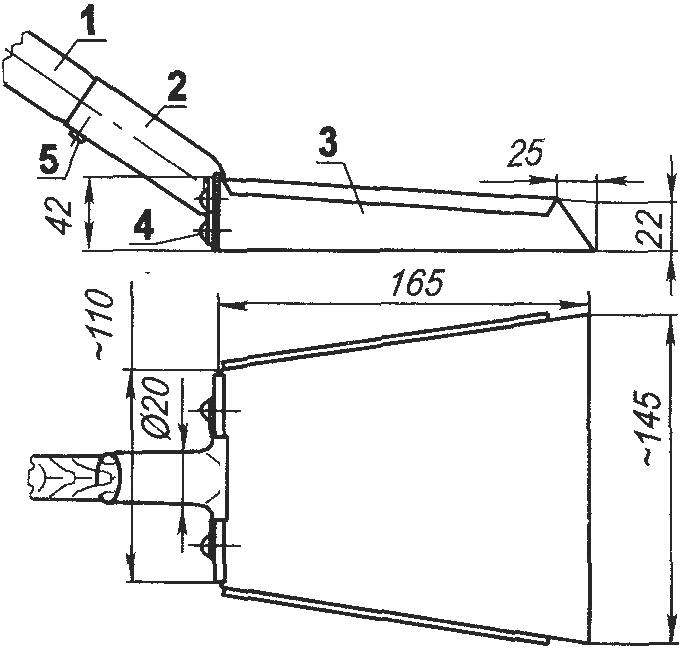

Household scoop:

1 — stick (pine, birch, aspen…); 2 — bushing (steel, sheet s0,5 — 0,6); 3 — ladle (steel, sheet s0,5 — 0,6); 4 — rivet (3 pieces); 5 — stopper (screw 3×10)

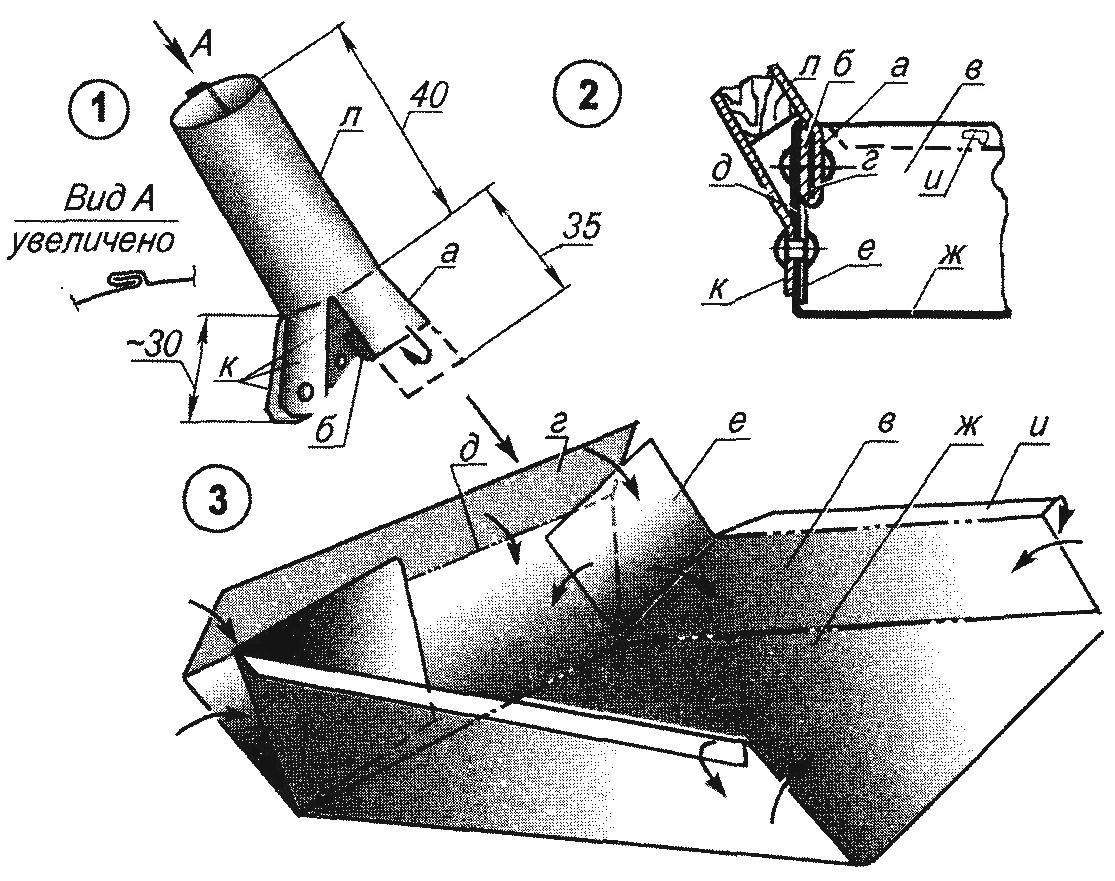

The formation of the bucket and the handle:

a,b — front tab-sleeve; in — Board of the bucket; g — lock; d — the rear exterior wall of the bucket; e — rear inner wall of the bucket; well — bucket basis; and — frame; rear feet of the sleeve; l — body bushings; 1 — sleeve; 2 — scoop Assembly; 3 — formation of the bucket

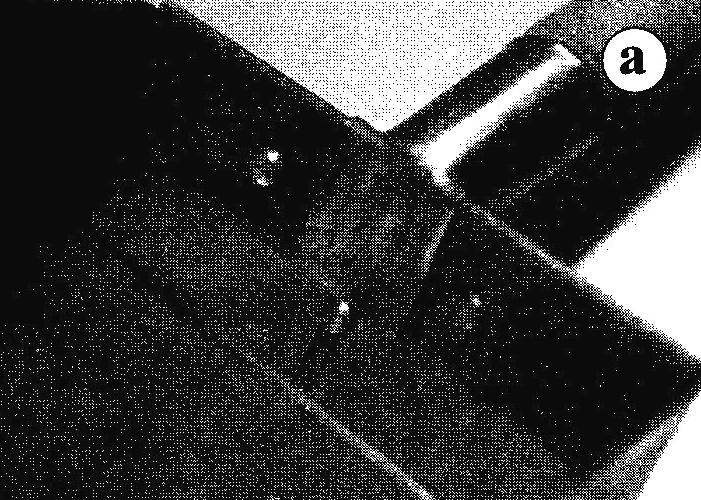

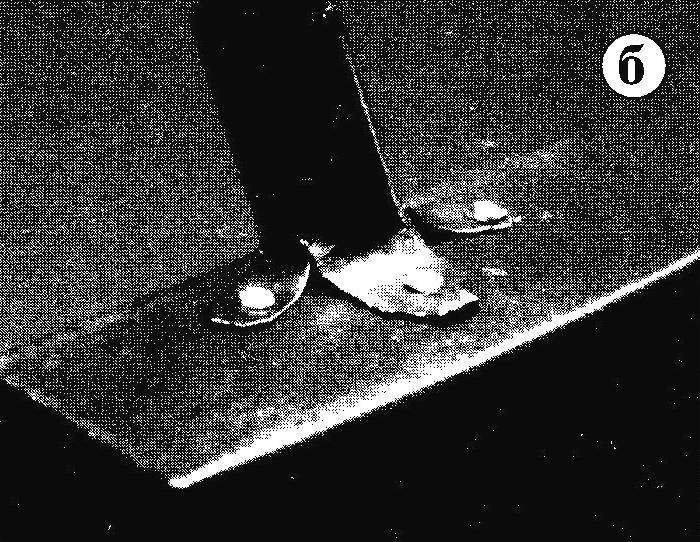

The fastening of the sleeve to the bucket (the inside view; b — back view)

For the manufacture of bushings were used steel mandrel with a diameter of 20 mm, the connection is simple the recumbent fold. The lower end of the sleeve on a length of about 35 mm that I cut into 4 feet: one (front) with a width of approximately 20mm (rear), narrower(10 — 11mm). These legs play a major role in ensuring the strength and rigidity of the connection node of the bushing with a bucket.

Manufacturer of bucket should be made in the following sequence:

— mark contour lines and bending according to the drawing of the sweep and cut the workpiece of 0.5 mm steel sheet;

— bend flanging “and” 180°;

— bend up the rear inner wall of the “e” bucket approximately 75 — 80°;

— bend the side “V” perpendicular to the base “W” of the bucket;

— bend up the lock “g” pre-85 — 95°;

— bend the rear outer wall of the “d” perpendicular to the base, and covered it with a castle “d” halves of the rear inner wall “e”;

— to have a foot “and the” sleeve below the castle, and feet “to” outside to the rear of the bucket;

— push the lock together with legs to the rear and hold in compressed position by means of clamps;

— to severity the 3 rivet holes and connect with them through the Bush with a bucket.

Foot sleeve, clasping the back wall of the bucket with two sides, provide the rigidity of the coupling and prevent the appearance of residual plastic deformation. The result is the required strength and durability of the product.

One of the scoops is made by me in the garden, and if necessary, I use it even when performing excavation work. Purchase at such “cruel” treatment has long been bent. And this is alive and well!

STEPANOV, Istra