For the Christmas tree offer a stand-technoise, which will serve not only the holidays, but all year round, in a variety of life situations — for fixing of racks, poles, etc., not to dig in them in the ground.

For the Christmas tree offer a stand-technoise, which will serve not only the holidays, but all year round, in a variety of life situations — for fixing of racks, poles, etc., not to dig in them in the ground. For home handymen — lovers to work with metal here is the drawing of this stand, which is quite clear and its design and even production technology.

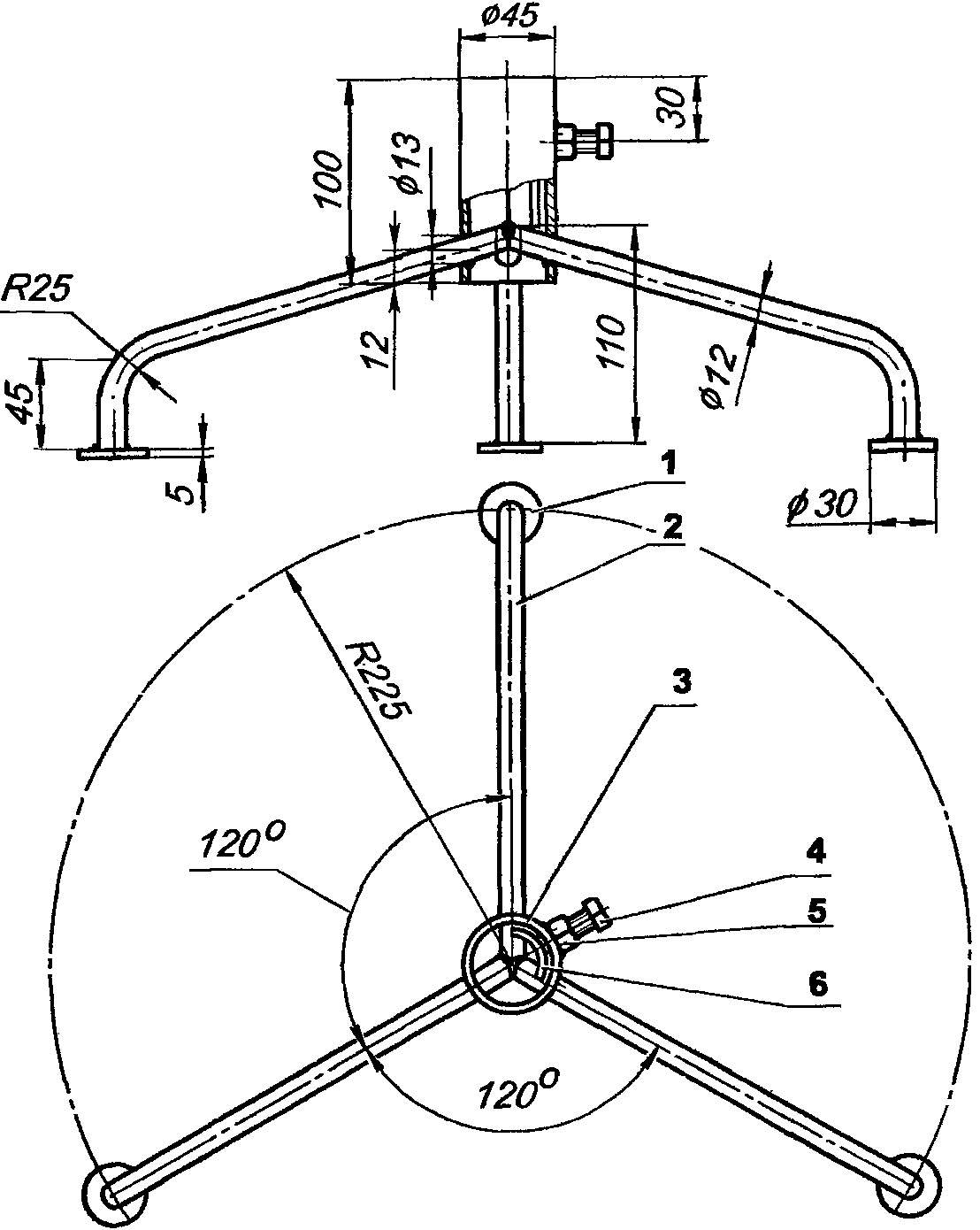

For the legs used thin-wall steel pipe outer diameter 12 mm, from the old beds, and the housing and lining — thick-walled segments of water with a diameter of 45 mm and a wall thickness of 2.5 mm. For the manufacture of a lining cut from the same tubular workpiece longitudinal third part and bent it to the outer radius of 20 mm.

Stand tripod for Christmas trees:

1 — thrust bearing (3 pieces); 2 — leg (tube Ø 12×1, 3). 3 — housing (tube Ø 45×2,5); 4 — clip (bolt M10); 5 — nut M10; 6 — lining (pipe Ø 40).

As a clamp for the lining used the M10 bolt with the same nut. The nut was welded to the housing, pre-drilled a hole with a diameter of 10.5 mm. the Lining to the clamp not welded — to fail it will not allow the converging inside the enclosure legs. As glides to the legs used furniture (wide) washers.

In washer-thrust drilled near the outer edges of the small holes (diameter 6 mm) — if necessary, through them, the stand can additionally be attached with screws to a wooden base (floor) or pins of wire, to the ground.

A. MATVEICHUK, Zavodoukovsk, Tyumen region.