Popularity of electronic musical instruments, an increasing number of Amateur youth and pop ensembles caused an increased demand for powerful, high quality low-frequency amplifiers. The industry has developed serial production of ULF with output power from 50 to 100 watts for a variety of ensembles (“trembita” 80 watts “Podilia” — 50 watt, ULF-100— 100 watts). Yes, and Amateurs created many interesting designs concert reinforcement equipment.

Popularity of electronic musical instruments, an increasing number of Amateur youth and pop ensembles caused an increased demand for powerful, high quality low-frequency amplifiers. The industry has developed serial production of ULF with output power from 50 to 100 watts for a variety of ensembles (“trembita” 80 watts “Podilia” — 50 watt, ULF-100— 100 watts). Yes, and Amateurs created many interesting designs concert reinforcement equipment.

However, without good sound speaker capabilities high quality amp be unused.

Readers sound column designed by engineer E. Avramenko. In three years of operation of the column with stavatti amplifier for bass guitar has been confirmed, the dignity of the structure.

In the column with 6 speakers 15ГД-10, manufactured by the Leningrad plant named after A. S. Popov. Instead, you can use speakers of a different type, but it will have to resize the column.

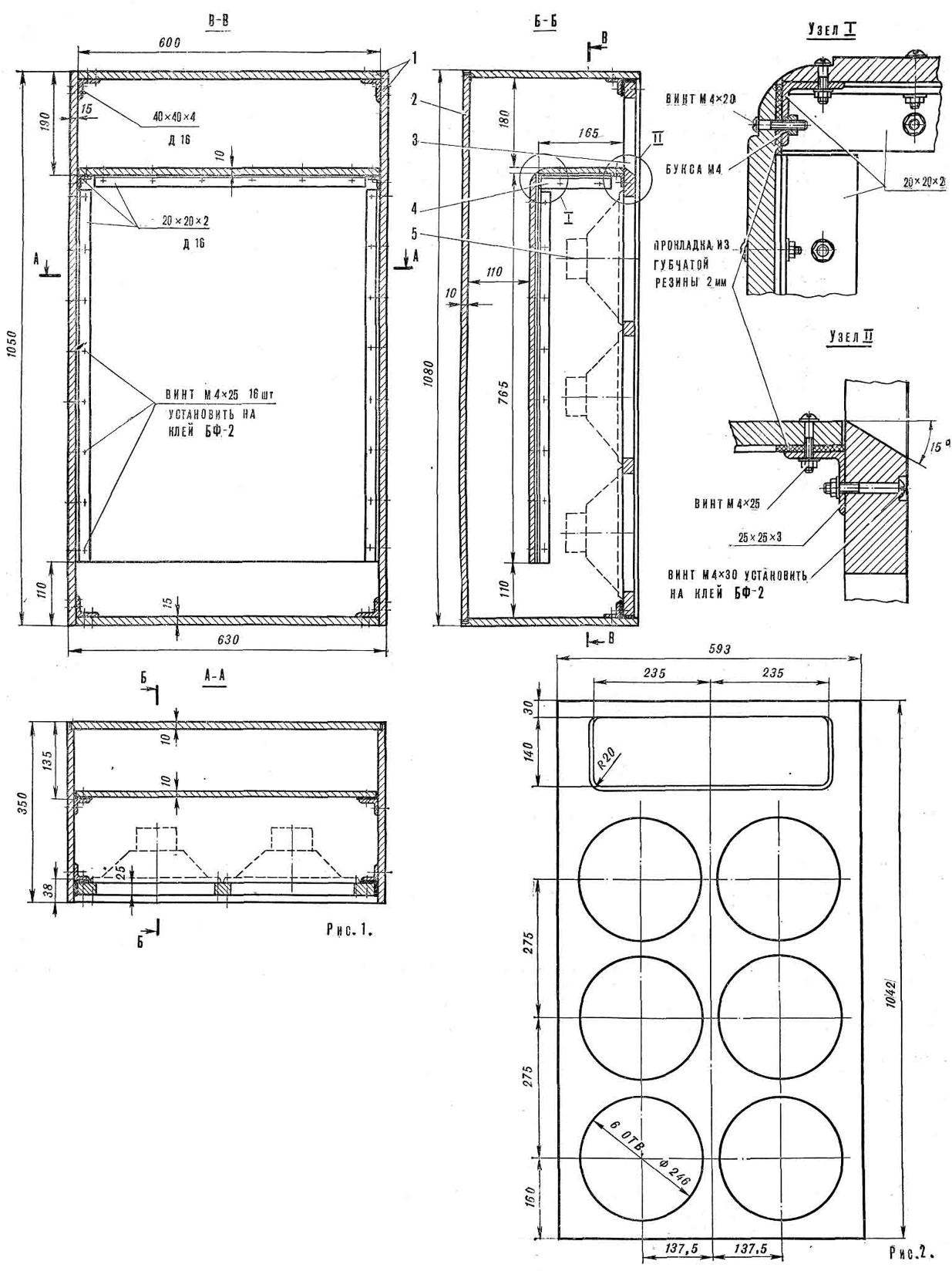

HOUSING column (Fig. 1) is produced of plywood or particle Board. Their dimensions are in millimeters and number: 1080X350X15 — 2; 630X350X15 — 2; 600X770X10 — 1; 600Х170Х10 — 1; 1045X595X25 — 1.

Fig. 1. Case (in section):

1, 2 — side and rear wall 3 — front Board 4 — partition of the acoustic labyrinth, the 5 — loudspeaker.

Fig. 2. The front Board.

Plywood panels are going on the spikes dovetail width 25 — 30 mm and fastened additionally dural area of size 40X40X4 mm. Such connection makes the whole construction more rigid and reduces the possibility of extraneous sounds at the resonant frequency.

ACOUSTIC LABYRINTH increases the impact of sound power speakers at frequencies below the resonant frequency of the speaker, improve the shape of their frequency response. It consists of horizontal and vertical partitions, which are attached to the body with dural corners size 20Х20Х2 mm using a cushioning strip of sponge rubber with a thickness of 2-3 mm. Vertical partition is removable, allowing access to the speakers. In reference shelves of the corners of the holes in which are mounted bushings with threaded screws М4Х20.

FRONT BOARD under the speakers is made of plywood or solid wood plate with a minimum thickness of 25 mm (Fig. 2).

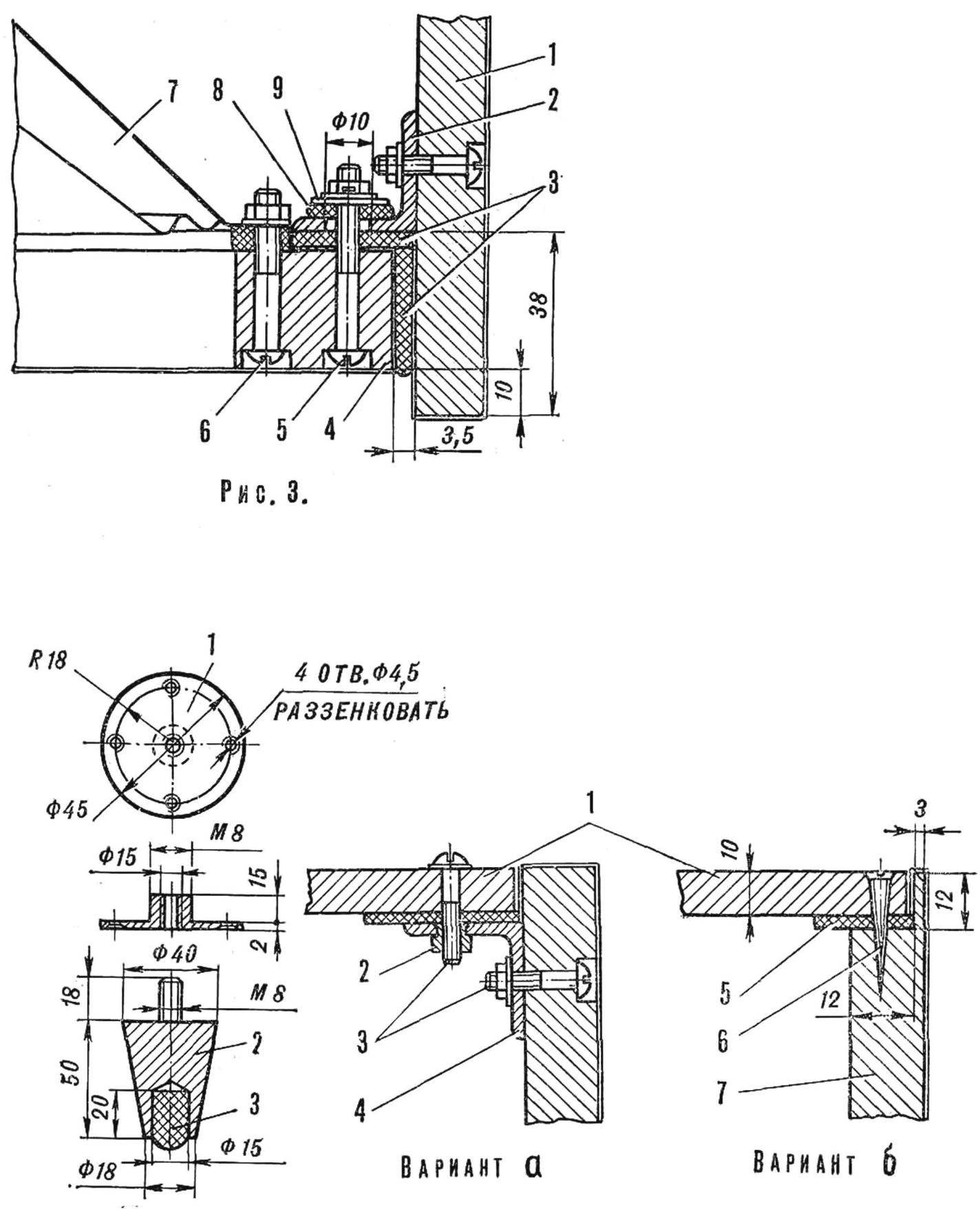

To reduce the transmission of vibration to the housing of the front Board is fastened to it using the shock absorbing pads of sponge rubber with a thickness of 4-5 mm. Mounting screws, the Board does not have hard contact with the seat angle. This is achieved by using a floating landing mounting screw in the base area with cushioning washers of sponge rubber (Fig. 3). The screws of the Board and speaker are rolled on glue BF-2 wpoty. They must make holes O 1,8 — 2,2 mm for cotter pins or lock nuts to use.

The front side of the front Board before her covered with radiomenu nitro dark color tones.

REAR panel of the column is solid, without holes and slots. Thereby increasing the efficiency of the column by the use of reflected sound energy.

Is attached to the rear wall of one of the methods shown in figure 5. In the shelves of seat angles to make the hole and install a bushing with thread M4 (Fig. 5A) or in the side walls of the casing column choose a groove size 12X12 mm (Fig. 5B). The rear wall is mounted through a cushioning strip of sponge rubber with a thickness of 2-3 mm. Distance between mounting screws is 100-110 mm.

DESIGN speakers carry out in such sequence. Paste over body faux leather or leatherette dark color. This produces the segment, equal in length to the perimeter of the body and 90-100 mm greater than the width. The junction features in the middle of the base of the column. After fining the side walls of the remaining material coated with glue, wrapped into the case and grab a Shoe of nails “Tex” with an interval of 10-12 mm. it is Recommended that casein glue or mastic for linoleum.

After the glue dries, the nails were removed and the excess material is trimmed. Care must be taken that no air bubbles and wrinkles.

The inner side of the housing and partitions the acoustic labyrinth hang loose felt with a thickness of 8-10 mm.

Fig. 4. Leg columns:

1 — faceplate (St. 3), 2 — leg (CT. 3), 3 — liner (rubber).

Fig. 5. Mount the rear wall:

1 — back, 2 — Bush M4, 3 — screw М4Х25 mm, 4 corner 20x20X2 mm (D16), 5— strip (sponge rubber), 6 — screw 3X30 mm, 7 — side

The front Board is covered with radiomenu or any other material with a loose structure. A piece of cloth 130-150 mm of more size of the Board is fixed on its corners. Next, the fabric is wrapped, pull, avoiding distortions, and grab on the reverse side of the Board hostami Shoe “Tex” 10-12 mm, starting from the middle of the larger side.

The end front of Board around the perimeter of the coat with a liquid casein glue. When the glue dries, nails are removed and the excess tissue is trimmed. After this surgery to the face Board with glue stick 88 padding of foam rubber in the thickness of 4-5 mm (Fig. 3). In conclusion, using the faceplates to the enclosure base to attach the legs with rubber liners (Fig. 4).

PHASE loudspeakers produced by a DC voltage of 9-12 V. If you connect loudspeakers to their diffusers should deviate to one side. Otherwise you need to swap insights voice coils on those speakers, diffusers which are deflected in the opposite direction.

After Assembly, verify the audio speakers in operating frequency range with a maximum mos,in particular, using a sound generator and a low frequency amplifier. If no resonant rattles and other extraneous sounds, making the column may be over.

MAIN SPECIFICATIONS SPEAKERS

Operating frequency range, Hz…………………………………………40-12000

The impedance at 1000 Hz

(depending on turn on the speakers), ?……84,0, 21,0, 9,4, 2,4

Nominal power, W…………………………………………..90

Dimensions, mm……………………………………………………………….1080х630х350

Weight………………………………………………………………………….28

E. AVRAMENKO